Method for preparing activated carbon for supercapacitors from camphor tree leaves

A technology of supercapacitor and activated carbon, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of high energy consumption, small specific surface area of activated carbon, and limited application of supercapacitors, and achieves easy availability of raw materials and equipment cost. Low, maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

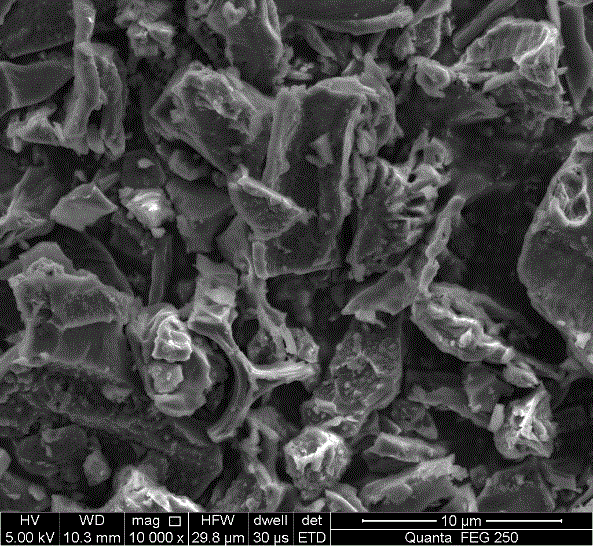

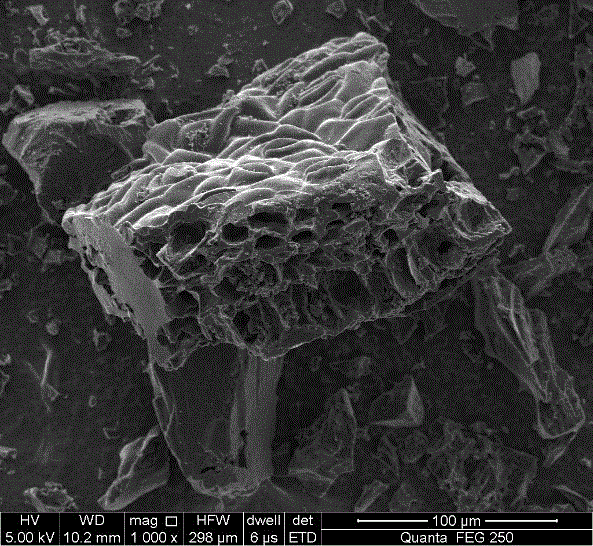

[0031] (1) After the raw material camphor leaves are washed with water to remove surface dust, they are dried in a blast drying oven at 80°C, and then the dried camphor leaves are broken into strip-shaped leaves with a width and length of 2-5mm using a crushing and shearing machine debris;

[0032] (2) Place the dried and crushed raw materials in step (1) in a tube furnace, carbonize and activate for 1 hour at 550°C under the protection of nitrogen;

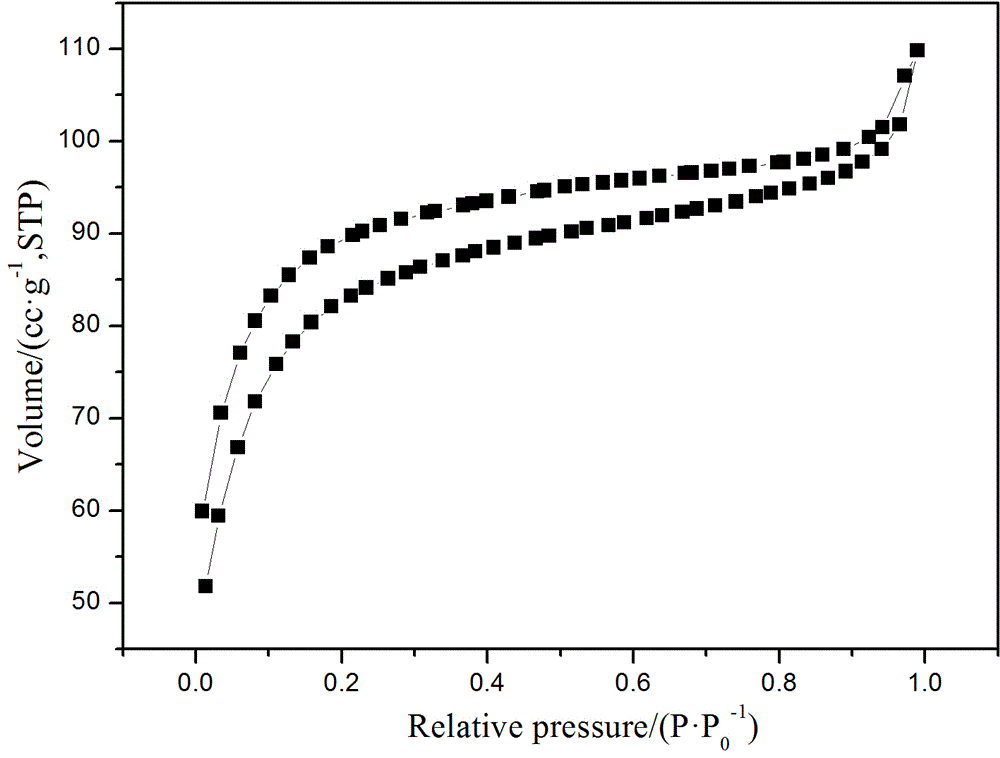

[0033] (3) Grind the carbonized raw materials in step (2), wash and filter with deionized water, wash the filter residue with 1mol / L hydrochloric acid solution at 30°C under stirring, and finally wash with deionized water until pH=6~7 ; The filter residue is first dried in a blast oven at 80°C for 12 hours, and finally dried in a vacuum oven at 120°C for 12 hours to obtain the finished activated carbon with a specific surface area of 311.32m 2 / g, at a discharge current of 300mA / g, its specific capacity can reach 15.57F / g.

Embodiment 2

[0035](1) After the raw material camphor leaves are washed with water to remove surface dust, they are dried in a blast drying oven at 80°C, and then the dried camphor leaves are broken into strips with a width and length of 2 to 5 mm using a crushing and shearing machine Fragments; broken raw materials, soaked in an appropriate amount of 6mol / L acid solution for 12 to 24 hours, and then dried at 140°C;

[0036] (2) Place the impregnated and dried raw materials in step (1) in a tube furnace, carbonize and activate for 1 hour at 500-550°C under the protection of nitrogen;

[0037] (3) Grind the carbonized raw materials in step (2), wash and filter with deionized water, wash the filter residue with 1~3mol / L hydrochloric acid solution at 40°C under stirring, and finally wash with deionized water until pH=6 ~7; The filter residue is first dried in a blast oven at 80°C for 12 hours, and finally dried in a vacuum oven at 120°C for 12 hours to obtain the finished activated carbon wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com