Device and method of utilizing solar energy light-heat-electric coupling to treat acrylonitrile sewage

A technology of acrylonitrile and solar energy, applied in the field of sewage treatment, can solve the problems of high energy consumption, complex electrocatalytic oxidation process route, etc., and achieve the effect of solving the complex process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation of acrylonitrile simulated sewage:

[0047] (1) Measure an appropriate amount of acrylonitrile, dissolve it in water to prepare a 1000 mg / L stock solution, store it at 4°C, and dilute it to the required concentration when used.

[0048] (2) Weigh an appropriate amount of sodium sulfate, dissolve it in water to form a 50g / L electrolyte stock solution, and dilute to the required concentration when used. Wherein the sodium sulfate concentration that adopts in the example is 5g / L.

[0049] 001 Indoor experimental research:

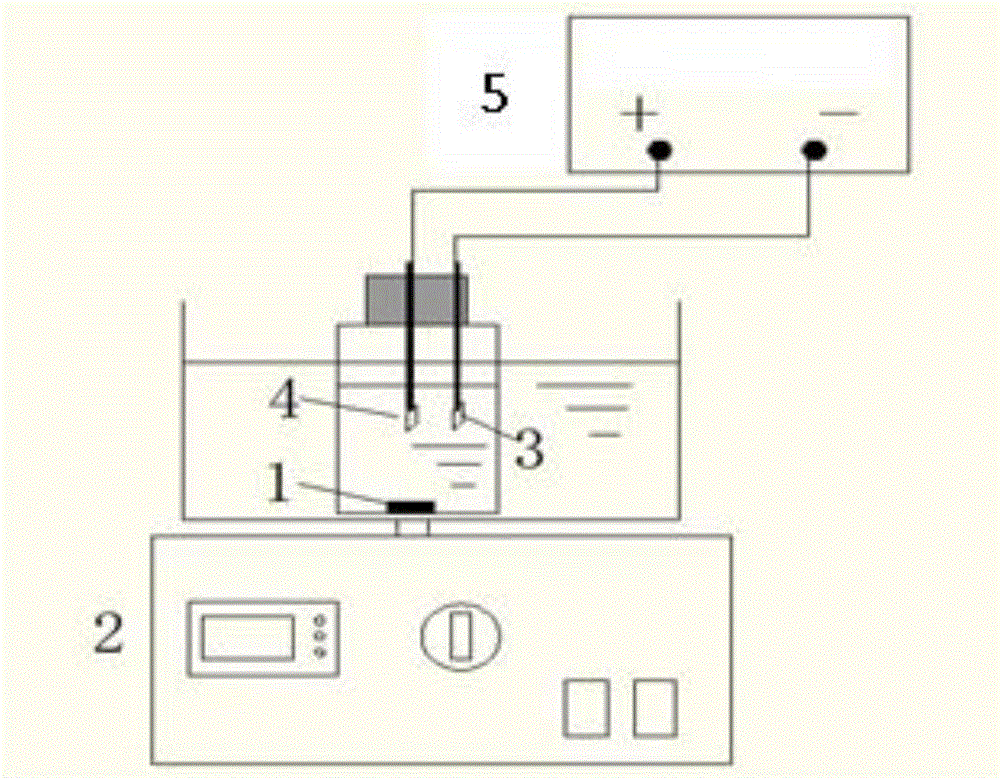

[0050] The indoor electrolysis device in this experiment is as follows: figure 1 shown, using figure 1 Middle 2 provides the temperature required for electrolysis and continues to stir, and at the same time uses a self-made glass container as an electrolytic cell to hold a well-mixed acrylonitrile electrolyte. A two-electrode system was used in the experiment, the cathode (such as figure 1 3) using pure platinum electrodes, the anode...

example 1

[0051] Example 1: The anode uses Ti / (IrO 2 &Ta 2 o 5 ) electrode, the cathode is a platinum electrode, with a rate of 6mA / cm 2 The current density is 40min, the reaction time is 40min, pH=3, and the reaction temperature is 50°C. The acrylonitrile wastewater with a concentration of 200mg / L is degraded, and the COD removal rate after degradation of the acrylonitrile wastewater is 48%.

example 2

[0052] Example 2: The anode uses Ti / (IrO 2 &Ta 2 o 5 ) electrode, the cathode is a platinum electrode, with a rate of 6mA / cm 2 The current density is 1h, the reaction time is 1h, the pH=7, and the reaction temperature is 50°C. The acrylonitrile wastewater with a concentration of 200mg / L is degraded, and the COD removal rate after degradation of the acrylonitrile wastewater is 47.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com