A process for realizing environmental protection and no discharge of penicillin production wastewater

A technology for the production of wastewater and penicillin, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of water resource waste and environmental damage, and achieve water conservation and obvious Environmental benefits, the effect of solving environmental protection wastewater problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

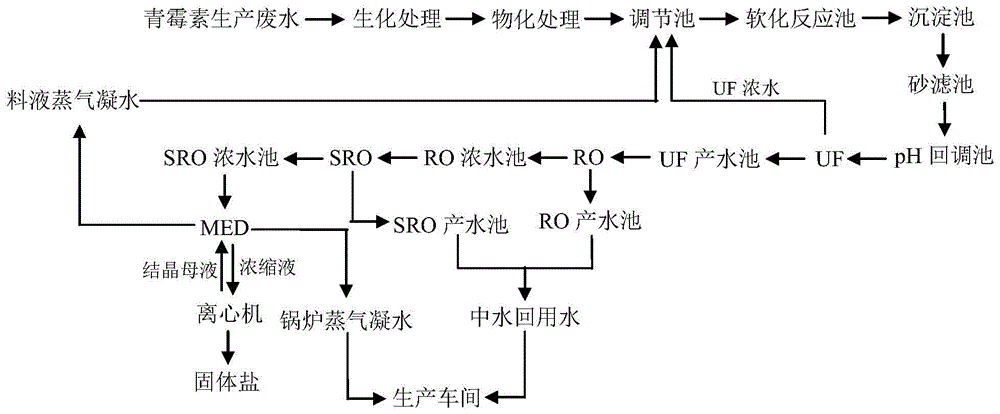

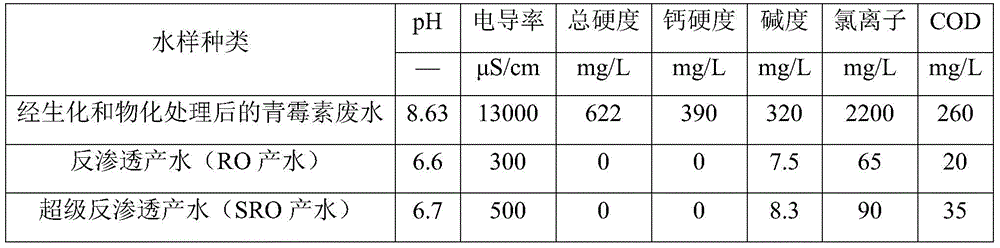

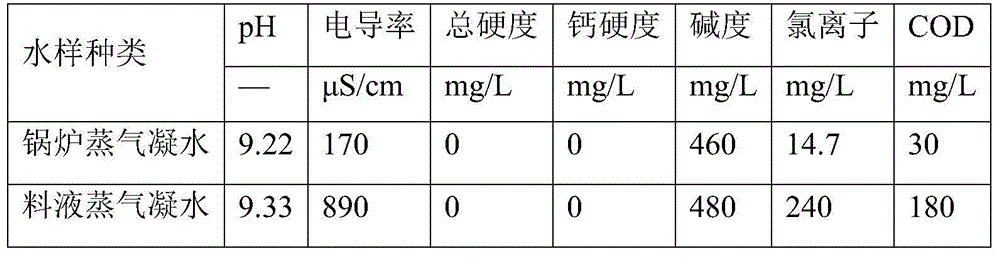

[0024] Embodiment 1 The process of realizing environmental protection and no discharge of penicillin production wastewater according to the present invention

[0025] (1) The penicillin waste water after biochemical and physicochemical treatment enters the regulating tank, and after stirring evenly with a submersible mixer, the waste water after the balanced water quality is obtained;

[0026] (2) the waste water after step (1) gained balance water quality enters softening reaction pool by adjusting tank, frame type agitator is housed in the softening reaction tank, regulates waste water pH=12.0 with 30% sodium hydroxide solution in softening reaction tank, Add polyacrylamide in an amount of 3ppm, the calcium and magnesium ions in the wastewater are precipitated in the form of calcium carbonate and magnesium hydroxide, and wastewater containing sediment is obtained;

[0027] (3) Step (2) gained waste water containing sediment enters the settling tank by the softening reaction ...

Embodiment 2

[0043] Embodiment 2 of the present invention realizes the process of environmental protection without discharge to penicillin production wastewater

[0044] (1) The penicillin waste water after biochemical and physicochemical treatment enters the regulating tank, and after stirring evenly with a submersible mixer, the waste water after the balanced water quality is obtained;

[0045](2) the waste water after the step (1) gained equilibrium water quality enters softening reaction tank by adjustment tank, frame type agitator is housed in the softening reaction tank, regulates waste water pH=12.3 with 30% sodium hydroxide solution in softening reaction tank, Add polyacrylamide in an amount of 3ppm, the calcium and magnesium ions in the wastewater are precipitated in the form of calcium carbonate and magnesium hydroxide, and wastewater containing sediment is obtained;

[0046] (3) Step (2) gained waste water containing sediment enters the settling tank by the softening reaction ta...

Embodiment 3

[0062] Embodiment 3 The process of realizing environmental protection and no discharge of penicillin production wastewater according to the present invention

[0063] (1) The penicillin waste water after biochemical and physicochemical treatment enters the regulating tank, and after stirring evenly with a submersible mixer, the waste water after the balanced water quality is obtained;

[0064] (2) the waste water after the step (1) gained equilibrium water quality enters softening reaction tank by adjustment tank, frame type agitator is housed in the softening reaction tank, regulates waste water pH=12.5 with 30% sodium hydroxide solution in softening reaction tank, Add polyacrylamide in an amount of 2.5ppm, the calcium and magnesium ions in the waste water are precipitated in the form of calcium carbonate and magnesium hydroxide, and waste water containing sediment is obtained;

[0065] (3) Step (2) gained waste water containing sediment enters the settling tank by the soften...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com