Feeding device and working method for oilfield waste treatment system

An oil field waste and treatment system technology is applied in the field of the feeding device of the oil field waste treatment system, which can solve the problems of incomplete treatment, insufficient heating of materials, and too many materials, so as to improve the efficiency and effect of treatment operations and improve work efficiency. Efficiency, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

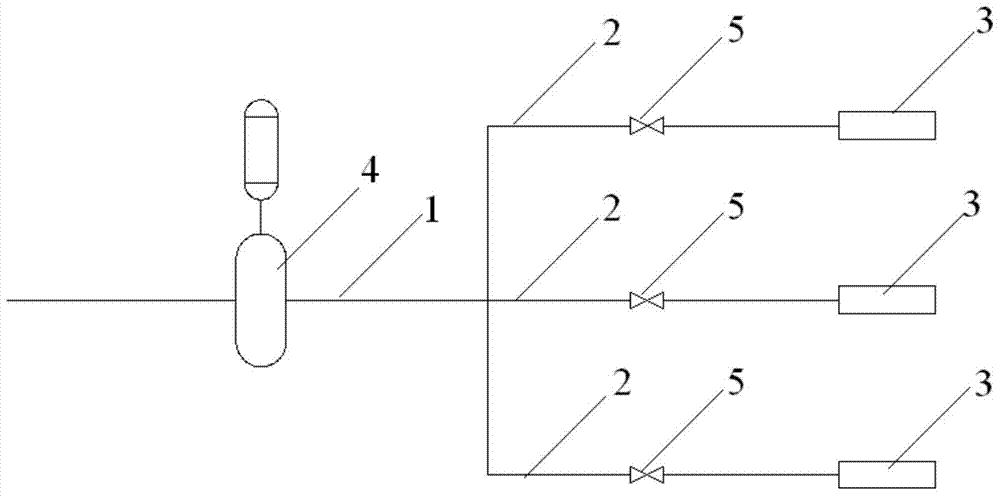

[0024] Such as figure 1 As shown, it includes a main pipe 1 and a plurality of branch pipes 2. The front ends of the branch pipes 2 are all connected to the rear end of the main pipe 1, and the rear ends of the branch pipes 2 are connected to the corresponding heating chamber 3. On the main pipe 1 A main mud pump 4 is installed, and the main mud pump 4 is a displacement pump, and branch valves 5 are installed on the branch pipes 2 .

[0025] When in use, first open the branch valve 5 on one branch pipe 2, and then close the branch valves 5 on the other branch pipes 2. The main mud pump 4 works to pump the material through the main pipe 1 to the corresponding branch pipe 2 and then into the Corresponding to the heating chamber 3.

[0026] After the main mud pump 4 runs for a set time T, close the opened branch valve 5, and then open the branch valve 5 on the next branch pipe 2, so that the material is pumped into the heating chamber 3 corresponding to the next branch pipe 2 ,...

Embodiment 2

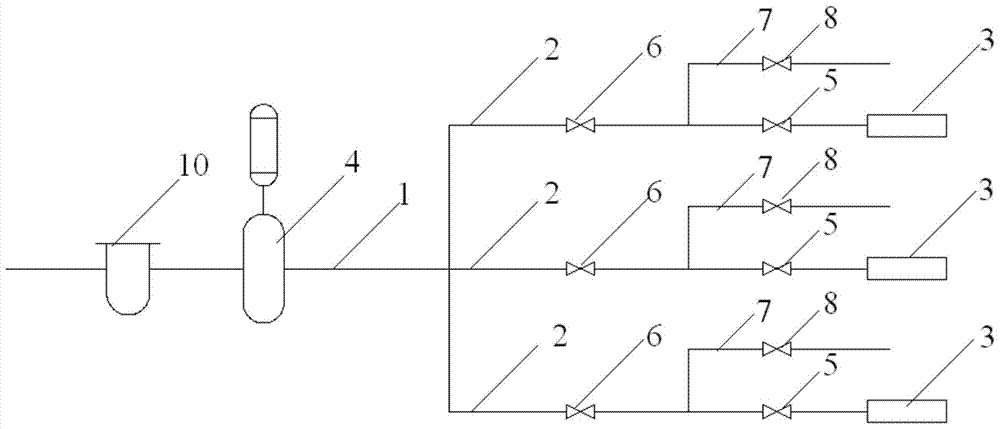

[0029] Such as figure 2 As shown, it has the same structure as that of Embodiment 1, and the different technical feature is that: the branch pipe 2 is equipped with a branch regulating valve 6, and the branch regulating valve 6 is located on the front side of the branch valve 5, and the branch A calibration pipe 7 is installed on the pipes 2, and the front end of the calibration pipe 7 is connected to the branch pipe 2. The connection point between the calibration pipe 7 and the branch pipe 2 is located between the branch regulating valve 6 and the branch valve 5. A calibration valve 8 is installed.

[0030] When in use, close the branch valve 5 of each branch pipe 2, and open the branch regulating valve 6 and calibration valve 8 on each branch pipe 2, use the main mud pump 4 to transport the material through the main pipe 1 to each branch pipe 2, and Discharge from each calibration tube 7. After each calibration tube 7 starts to discharge the material, the amount of materi...

Embodiment 3

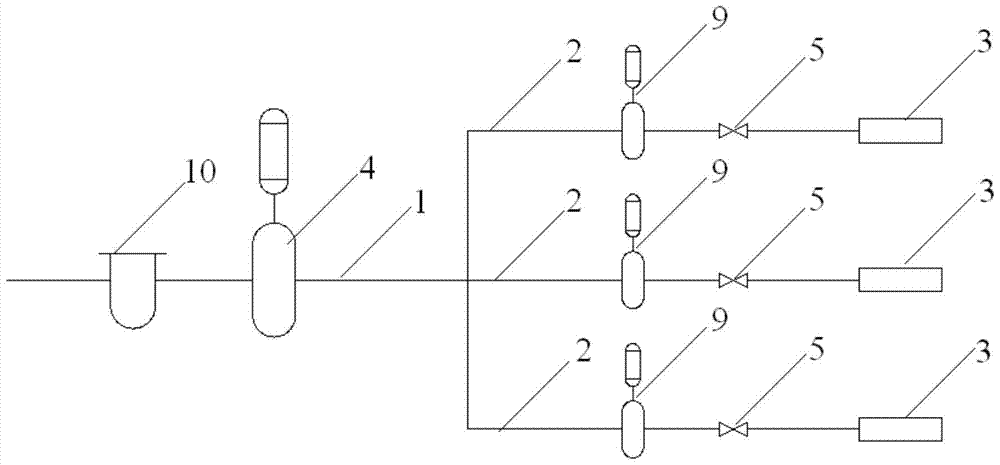

[0033] Such as image 3 As shown, it has the same structure as Embodiment 1, and the difference technical feature is that branch mud pumps 9 are installed on the branch pipes 2, and the branch mud pumps 9 are also displacement pumps, located at the side of the branch valve 5. front side.

[0034] The displacements of the branch mud pumps 9 are all the same, and are all smaller than the main mud pump 4 .

[0035] When in use, the main mud pump 4 transports the material to each branch pipe 2 through the main pipe 1, and then the branch mud pump 9 on each branch pipe 2 pumps the material into each heating chamber 3.

[0036] Since the branch mud pump 9 is a positive displacement pump, the amount of material delivered by each revolution or each stroke of its operation is constant. During the working process, the motor frequency of each branch mud pump 9 is maintained at the same value, and the displacement of the main mud pump 4 must be matched with the total intake of each bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com