Control method for frequency-conversion power supply circuit starting process of magnetron

A technology of variable frequency power supply and control method, which is applied in induction heating control, conversion equipment for intermediate conversion to DC conversion, induction heating, etc. Small overvoltage, good self-adaptive ability, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

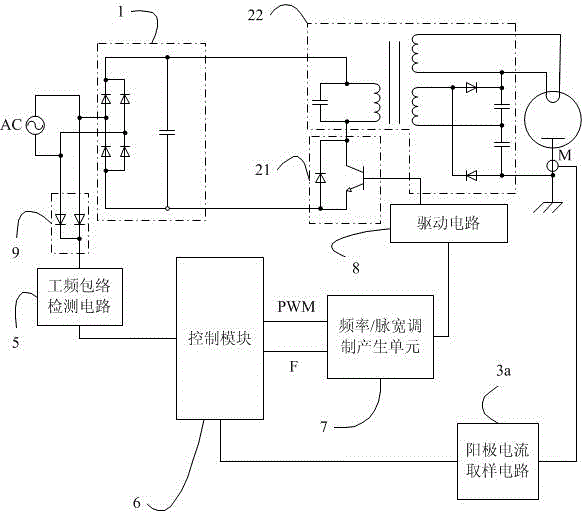

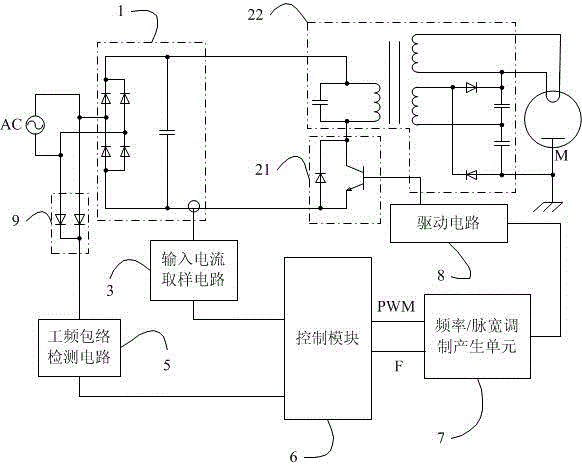

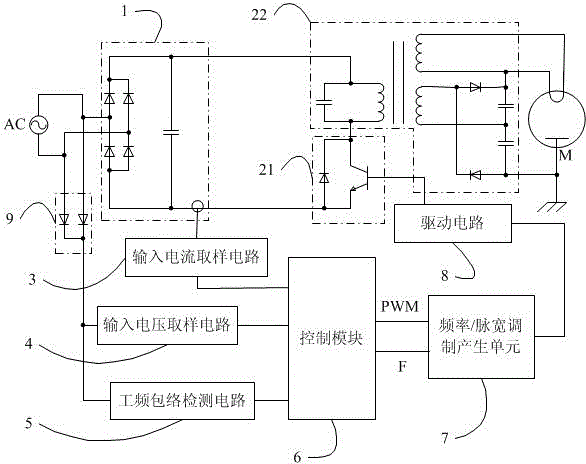

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0059] Aiming at the shortcomings of current products, the present invention finds out the characteristics of the start-up process of the magnetron, and proposes a new control method for the start-up process of the magnetron frequency conversion power supply circuit. Start the initial output power for the variable frequency power supply, then follow the process of increasing the anode current of the magnetron, and then gradually increase the output power of the power supply until the magnetron starts to vibrate.

[0060] The startup process of the present invention is divided into the following stages:

[0061] Stage 1: Start with micro energy and no impact: the variable frequency power supply starts with its minimum output power, which is less than the rated filament power of the magnetron;

[0062] Stage 2: Filament heating power setting: Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com