Optical film

A technology of optical film and polarizing layer, applied in the field of optical film, can solve the problems of picture brightness deterioration and invisible images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

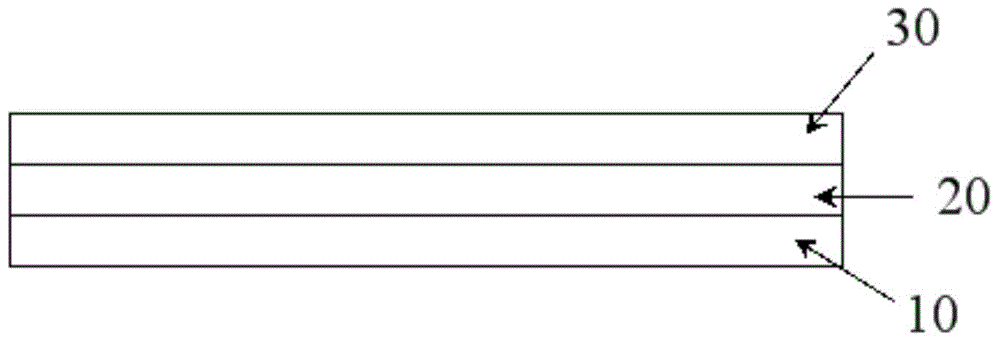

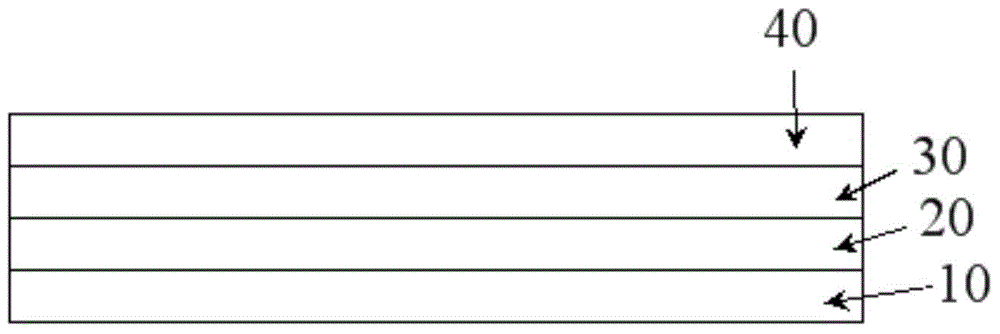

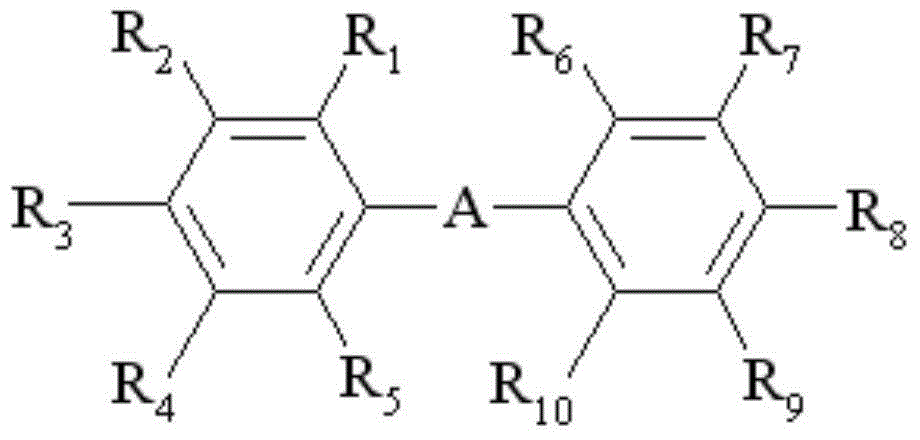

Method used

Image

Examples

Embodiment 1 to 4 and comparative Embodiment 1 to 4

[0139] By dissolving 20 g of 5-norbornenyl-2-methyl-(4-methoxycinnamate) as a photoreactive polymer in 980 g of cyclopentanone, 20 g of dipentaerythritol hexaacrylate and as a photoinitiator 5g Irgacure OXE02 (Ciba-Geigy company, Switzerland) to prepare the coating solution for forming the alignment layer, the coating solution is coated on the triacetyl cellulose (TAC) film so that it has about thickness, and dried in a 70°C drying oven for 2 minutes with hot air, thereby forming a layer. Next, the TAC film having the layer was conveyed in one direction, and while using a high-pressure mercury lamp (80 w / cm) as a light source, and a wire grid polarizing plate (Moxtek Corporation) to irradiate the film with linearly polarized ultraviolet rays Exposure was performed once at a rate of 3 m / min, whereby alignment characteristics were obtained.

[0140] Subsequently, a coating solution for forming a liquid crystal layer having a solid content of about 25% by weight was prepared by...

Embodiment 5

[0147] By the same procedure as described in Example 1, except that an antistatic agent (methacryloylcholine chloride, TCI) was added to the mixture of the polymerizable liquid crystal compound and the reactive non-liquid crystal compound to have a concentration of 3% by weight The same process formed the optical film.

Embodiment 6

[0149] In addition to using a conductive polymer (Aedotron TM ) instead of the TAC film, an optical film was formed by the same process as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com