Cow and goat milk compound infant formula milk powder and preparation method thereof

A technology of infant formula and goat milk powder, applied in dairy products, milk preparations, applications, etc., can solve the problems of not being able to give full play to the nutritional effects of cow's milk and goat's milk, and not improve the nutritional content and taste, and achieve Effects of retaining nutrients, alleviating allergies, and preventing adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

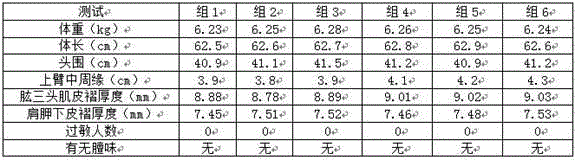

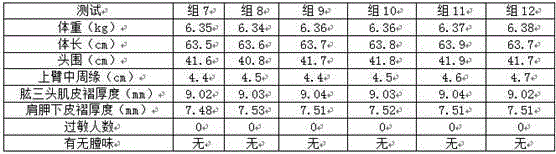

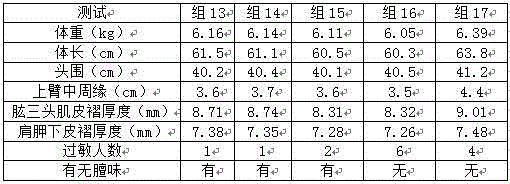

Examples

Embodiment 1

[0039] A method for preparing infant formula milk powder compounded with cow and goat milk comprises the following steps in sequence:

[0040] (1) Mix 180 parts of fresh goat milk, 8 parts of concentrated goat whey protein powder, 8 parts of vegetable oil, 0.5 parts of milk fat, 35 parts of lactose, 0.5 parts of fructo-oligosaccharide and 1.5 parts of galacto-oligosaccharide in parts by weight. Stir at 40°C until completely dissolved to obtain a mixed solution; wherein, fresh goat milk contains 13% dry matter;

[0041] (2) Homogenize the mixed solution at 15MPa, and control the temperature at 40°C;

[0042] (3) Temporary cooling at a temperature of 1°C for no more than 12 hours;

[0043] (4) Concentrate and spray dry to obtain powdery base powder, the concentration temperature is 40°C; when spray drying, the inlet air temperature is 150°C, and the exhaust air temperature is 80°C;

[0044] (5) Add 0.2 part of ARA, 0.15 part of DHA, 0.1 part of multivitamin, and 1 part of mult...

Embodiment 2

[0049] A method for preparing infant formula milk powder compounded with cow and goat milk comprises the following steps in sequence:

[0050] (1) Mix 380 parts of fresh goat milk, 14 parts of concentrated goat whey protein powder, 15 parts of vegetable oil, 2.5 parts of milk fat, 46 parts of lactose, 1 part of fructo-oligosaccharide and 1 part of galacto-oligosaccharide in parts by weight. Stir at 50°C until completely dissolved to obtain a mixed solution; wherein, fresh goat milk contains 10% dry matter;

[0051] (2) Homogenize the mixed solution at 20MPa, and control the temperature at 50°C;

[0052] (3) Temporary cooling at a temperature of 10°C for no more than 12 hours;

[0053] (4) Concentrate and spray dry to obtain powdery base powder, the concentration temperature is 50°C; when spray drying, the inlet air temperature is 170°C, and the exhaust air temperature is 90°C;

[0054] (5) Add 0.6 parts of ARA, 0.5 parts of DHA, 0.2 parts of multivitamins, and 0.5 parts of m...

Embodiment 3

[0059] A method for preparing infant formula milk powder compounded with cow and goat milk comprises the following steps in sequence:

[0060] (1) Mix 280 parts of fresh goat milk, 10 parts of concentrated goat whey protein powder, 12 parts of vegetable oil, 1.5 parts of milk fat, 40 parts of lactose, 0.9 parts of fructo-oligosaccharide and 1.2 parts of galacto-oligosaccharide in parts by weight. Stir at 45°C until completely dissolved to obtain a mixed solution; wherein, fresh goat milk contains 12% dry matter;

[0061] (2) Homogenize the mixed solution at 18MPa, and control the temperature at 45°C;

[0062] (3) Temporary cooling at a temperature of 5°C for no more than 12 hours;

[0063] (4) Concentrate and spray dry to obtain powdery base powder, the concentration temperature is 45°C; when spray drying, the inlet air temperature is 160°C, and the exhaust air temperature is 85°C;

[0064] (5) Add 0.4 parts of ARA, 0.3 parts of DHA, 0.18 parts of multivitamins, and 0.8 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com