Super-hydrophobic cigarette end, preparation method and uses thereof

A super-hydrophobic, hookah technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of high cost, harsh preparation material conditions, unsuitable for large-scale production and use, and achieves low cost and simple preparation method. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of superhydrophobic cigarette butts: immerse waste cigarette butts in deionized water for 30 minutes and take them out, immerse them in absolute ethanol for 30 minutes, take out the cigarette butts and dry them under normal pressure at 60°C for 2 hours to obtain clean cigarette butts; Cetyl trichlorosilane n-hexane solution 20mL, soak the clean cigarette butts in it for 2 minutes, take out and soak in n-hexane for 30 minutes, wash off the unreacted cetyl trichlorosilane remaining on the surface, take out the cigarette butts and put them in the oven Dry at 80°C for 1 hour, and cool naturally to obtain superhydrophobic cigarette butts.

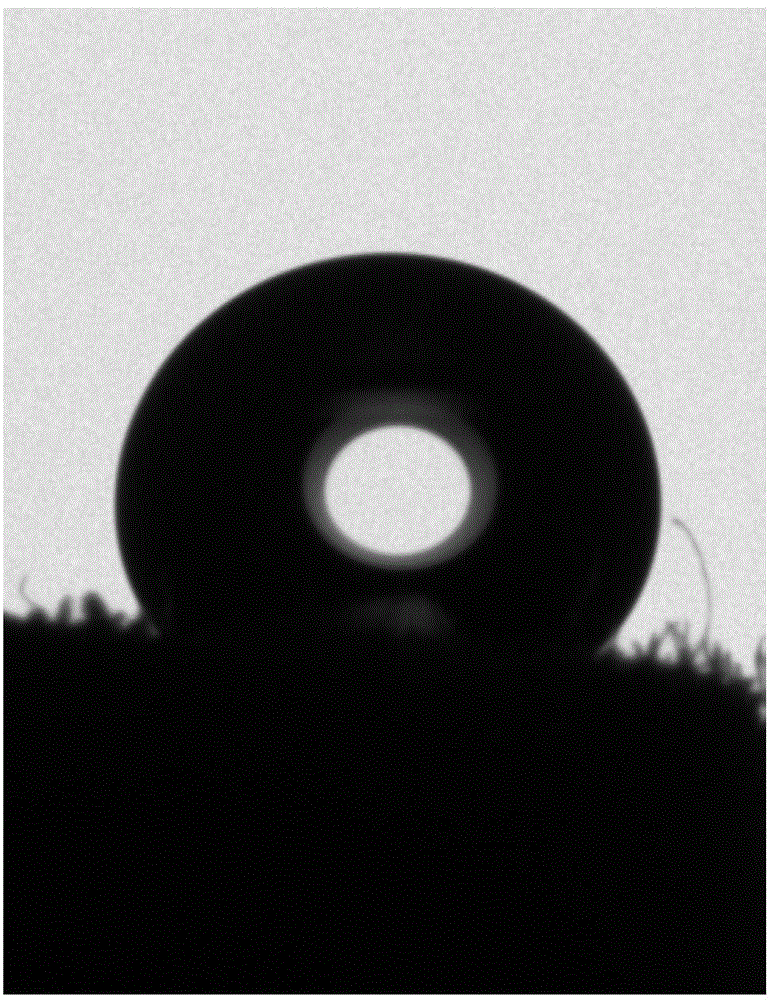

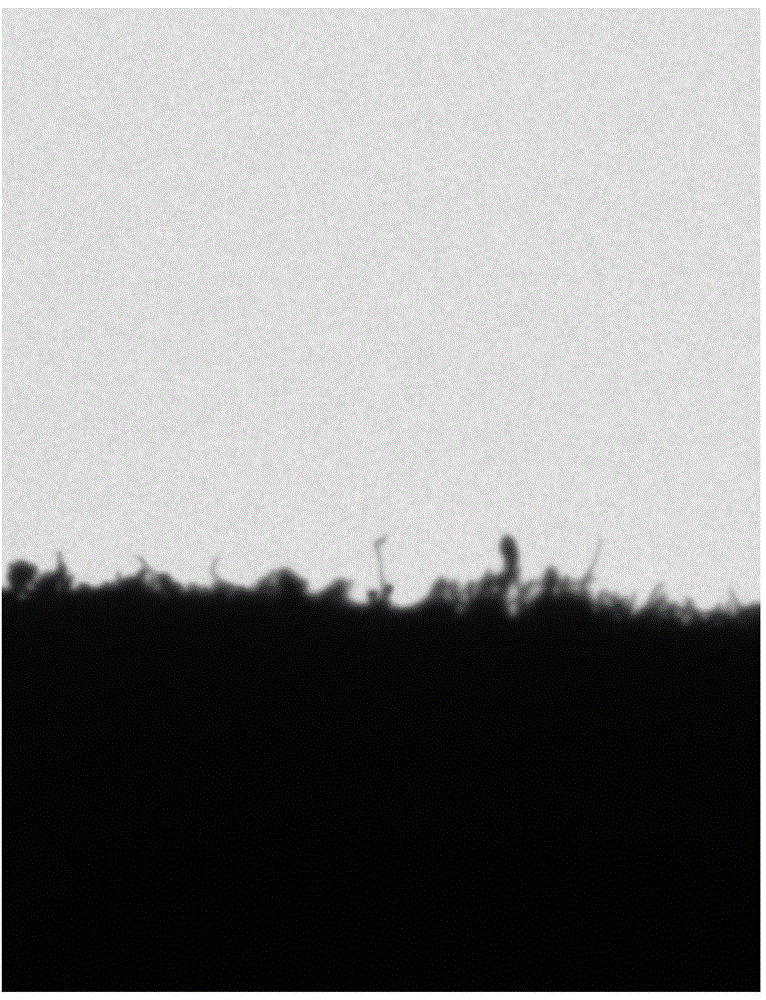

[0027] Such as figure 1 , figure 2 The contact angles of the superhydrophobic cigarette butts described in this example to water and to cetane indicate that the superhydrophobic cigarette butts of the present invention have hydrophobic and lipophilic properties.

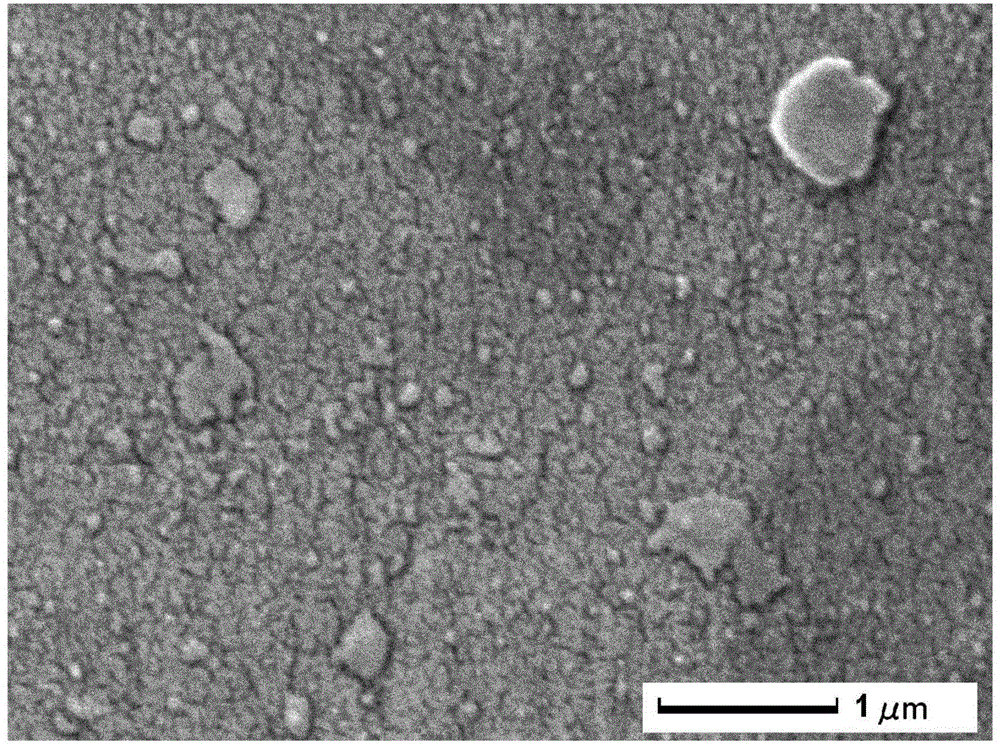

[0028] Such as image 3 The high-power electron microsco...

Embodiment 2

[0033] 1. Preparation of superhydrophobic cigarette butts: immerse discarded cigarette butts in deionized water for 30 minutes and take them out, immerse them in acetone for 30 minutes, and then take out the cigarette butts and dry them under normal pressure at 60°C for 2 hours to obtain clean cigarette butts; prepare 2% octadecyl tri 20mL of n-pentane solution of chlorosilane, soak the clean cigarette butt in it for 5min, take it out and soak it in n-pentane for 30min, wash off the unreacted octadecyl trichlorosilane remaining on the surface, take out the cigarette butt and put it in an oven at 70 Dry at ℃ for 1.5h, and cool naturally to obtain superhydrophobic cigarette butts.

[0034] Preparation of oil-water emulsion: Mix 10 mL of deionized water and 90 mL of hexadecane, add 0.5 g of Span 80, ultrasonically disperse for 2 hours, and disperse evenly to obtain an oil-water emulsion.

[0035] The superhydrophobic cigarette butt is clamped in the middle of the glass separator,...

Embodiment 3

[0037] 1. Preparation of superhydrophobic cigarette butts: immerse waste cigarette butts in deionized water for 30 minutes and take them out, immerse them in methanol for 30 minutes, take out the cigarette butts and dry them under normal pressure at 60°C for 2 hours to obtain clean cigarette butts; prepare 4% cetyl tris 20mL of n-pentane solution of chlorosilane, soak the clean cigarette butt in it for 5min, take it out and soak it in n-pentane for 30min, wash off the unreacted cetyltrichlorosilane remaining on the surface, take out the cigarette butt and put it in an oven at 90 Dry at ℃ for 40 minutes, and get superhydrophobic cigarette butts after natural cooling.

[0038] Preparation of oil-water emulsion: Mix 10 mL of deionized water and 90 mL of isooctane, add 0.5 g of Span 80, ultrasonically disperse for 2 hours, and disperse evenly to obtain an oil-water emulsion.

[0039] The superhydrophobic cigarette butt is clamped in the middle of the glass separator, and the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com