Liquid-gas mixer and gas-liquid recovery device by employing liquid-gas mixer

A technology of liquid-gas mixing and mixing chamber, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of waste gas recovery liquid-gas mixers that have not yet been found, and achieve reasonable vertical distribution and realize recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

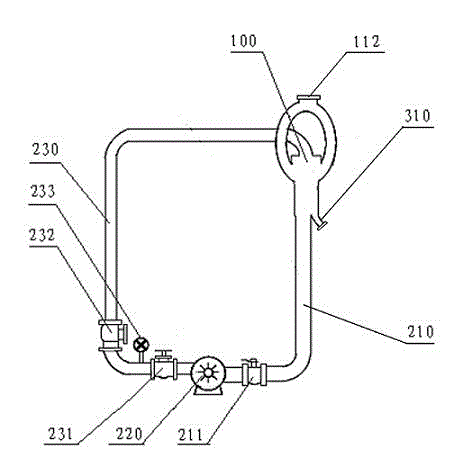

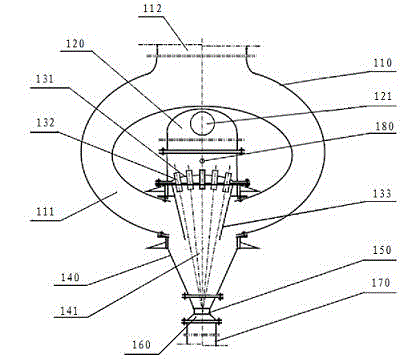

[0010] see figure 1 and figure 2 , the liquid-gas mixer 100 involved in the present invention is mainly composed of an interconnected power drive chamber 120 and a jet mixing chamber, both of which are vertical or horizontal, and the power drive chamber is located in the Above the jet mixing chamber (vertical type) or front end (horizontal type, etc.), the liquid-gas mixer is provided with the partition 131 of the power drive chamber and the jet mixing chamber, and several injection pipes are installed on the partition 132. For example, it can be fixedly welded or fastened with fastening nuts from above, below, or from left and right. The inlet end of the injection pipe is located in the power driving chamber, and the outlet end is located in the jet mixing chamber.

[0011] Preferably, the jet form of each spray pipe is preferably substantially non-diffused or less diffused, so that these small jet streams 141 can be converged into a tapered large jet with a water cross sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com