Method of refining silicon with non-graphite crucible on medium-frequency furnace

An intermediate frequency furnace, non-graphite technology, applied in chemical instruments and methods, silicon compounds, non-metallic elements, etc., can solve the problems of high-purity silicon metal pollution, inapplicability, etc., to reduce smelting costs, improve production efficiency, block The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

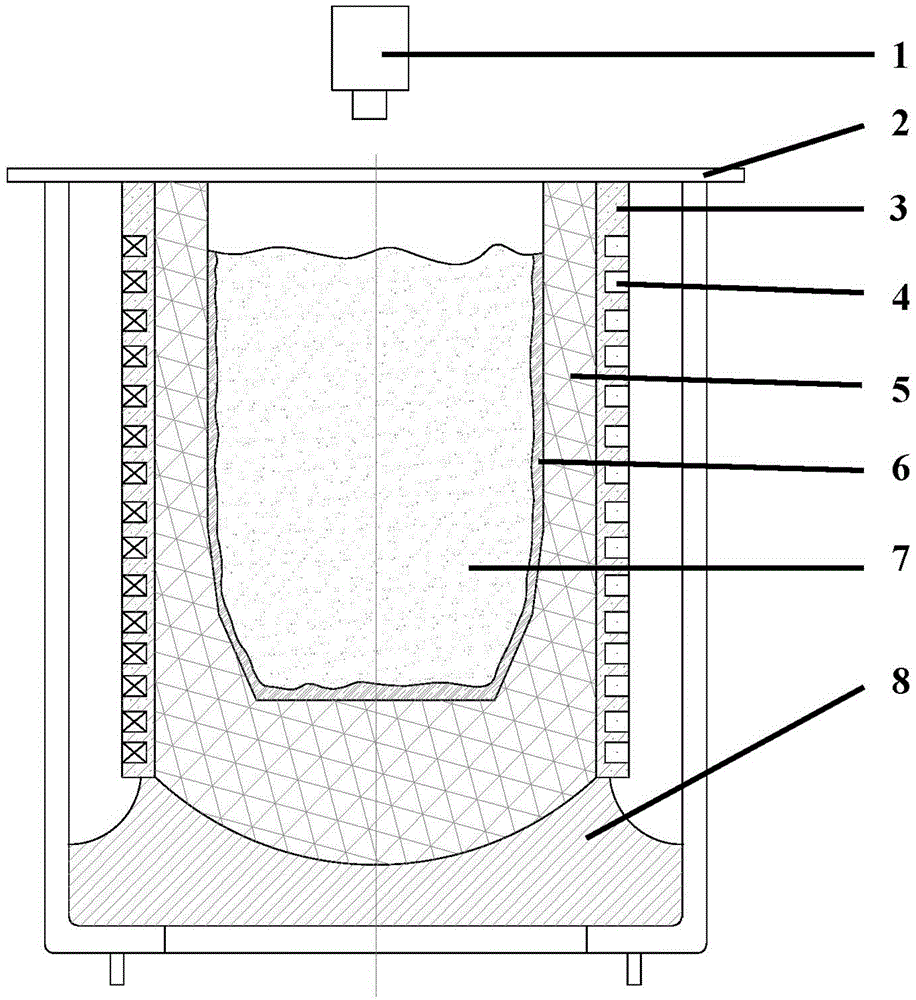

[0030] Such as figure 1 As shown, the non-graphite crucible of the present invention includes an infrared thermometer 1, an intermediate frequency furnace shell 2, a coil red mud 3, a water-cooled coil 4, a cast molding crucible (prefabricated crucible) 5, a silicon slag protective layer 6, and a silicon melt 7. Refractory cement8. Coil red mud 3 is applied to the inside of the water-cooled coil 4, and the coil red mud 3 is baked and sintered. After the sintering of the coil red mud 3 is completed, a crucible mold is built in the intermediate frequency furnace, and the castable is used to cast the crucible 5, or the prefabricated crucible 5 is placed in the intermediate frequency furnace, and the surrounding is filled with dry vibration material. During smelting, a silicon slag protective layer 6 is formed in the crucible 5 , and refractory cement 8 is filled between the bottom of the crucible 5 and the shell 2 of the intermediate frequency furnace. Inside the crucible 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com