Cement grinding aid composition by taking glycerinum distillation residues as main raw material as well as preparation method and application thereof

A technology of cement grinding aid and distillation residue, applied in the field of cement grinding aid composition, can solve the problems of poor grinding aid effect and the like, and achieve the effects of more full utilization, high utilization, good grinding aid and enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

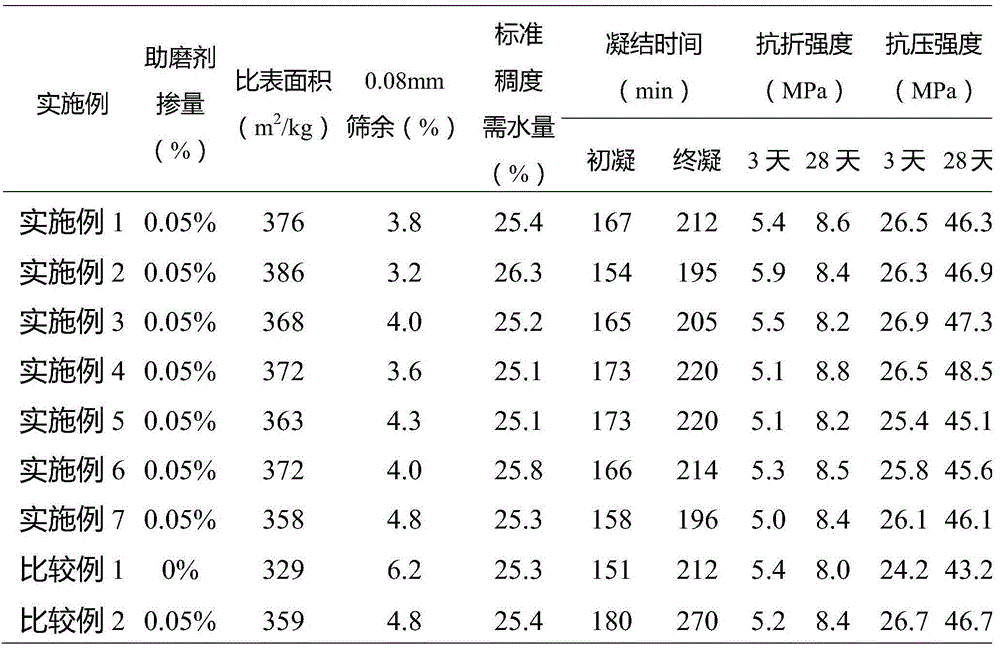

Examples

Embodiment 1

[0031] During the production process of chemically synthesizing glycerin in a factory, the mass composition of the glycerin distillation residue discharged is 35% sodium chloride, 18% glycerin, 8% polymerized glycerin, and the balance is water.

[0032] Step a): Get 1000g of glycerin distillation residue, centrifuge to remove most of the sodium chloride, take 500g of the separated liquid phase I, add 1500g of absolute ethanol, after fully stirring, filter off the inorganic salts to obtain the liquid phase II, and use Ethanol is distilled off under normal pressure in the distiller until the mixture has a constant weight to obtain a mixture A whose main component is glycerol and polyglycerol;

[0033] Step b): Take 100 g of the mixture A obtained in step a) and add it to the reaction kettle, insert a copper wire with a diameter of 2 mm in the kettle, and insert the copper wire into the reaction medium, then add 1 g of sodium carbonate as a catalyst, turn on the nitrogen protectio...

Embodiment 2

[0040] During the production process of chemically synthesizing glycerin in a certain factory, the mass composition of the glycerin distillation residue excluded is 20% sodium chloride, 20% glycerin, 10% polymerized glycerin, and the balance is water.

[0041] Step a): Get 1000g of glycerin distillation residue, centrifuge to remove most of the sodium chloride, take 500g of the separated liquid phase I, add 2000g of absolute ethanol, after fully stirring, filter off the inorganic salts to obtain the liquid phase II, and use Ethanol is distilled off under normal pressure in the distiller until the mixture has a constant weight to obtain a mixture A whose main component is glycerol and polyglycerol;

[0042] Step b): Take 100g of the mixture A obtained in step a) and add it to the reaction kettle, insert a copper wire with a diameter of 2mm in the kettle, insert the copper wire into the reaction medium, add 3g of sodium carbonate as a catalyst, turn on the nitrogen protection, an...

Embodiment 3

[0046] During the production process of chemically synthesizing glycerin in a factory, the mass composition of the glycerin distillation residue discharged is 50% sodium chloride, 10% glycerin, 5% polymerized glycerin, and the balance is water.

[0047] Step a): Take 1000g of glycerin distillation residue, centrifuge to remove most of the sodium chloride, take 400g of the separated liquid phase I, add 3000g of absolute ethanol, stir well, filter off the inorganic salts, obtain the liquid phase II, and use Ethanol is distilled off under normal pressure in the distiller until the mixture has a constant weight to obtain a mixture A whose main component is glycerol and polyglycerol;

[0048] Step b): Take 100g of the mixture A obtained in step a) and add it to the reaction kettle, insert a copper wire with a diameter of 2mm in the kettle, insert the copper wire into the reaction medium, then add 2g of sodium carbonate as a catalyst, turn on the nitrogen protection, and heat React ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com