Classified filtering pre-liming tank

A technology of graded filtration and pre-ash bucket, which is applied in the direction of purification with alkaline earth compounds and purification with physical methods, which can solve the problems of serious energy consumption and complicated process, and achieve the effects of convenient operation, low energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

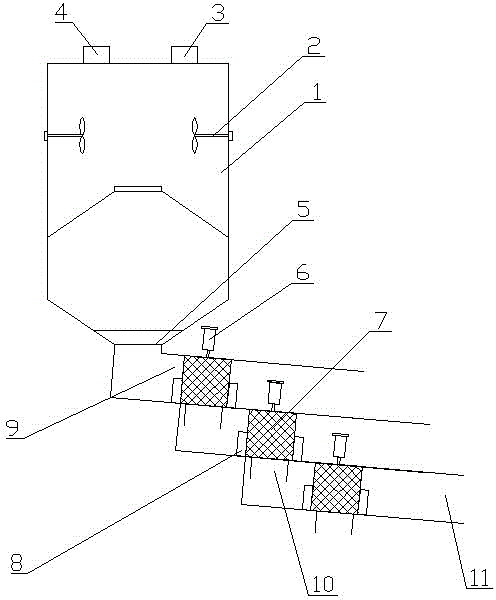

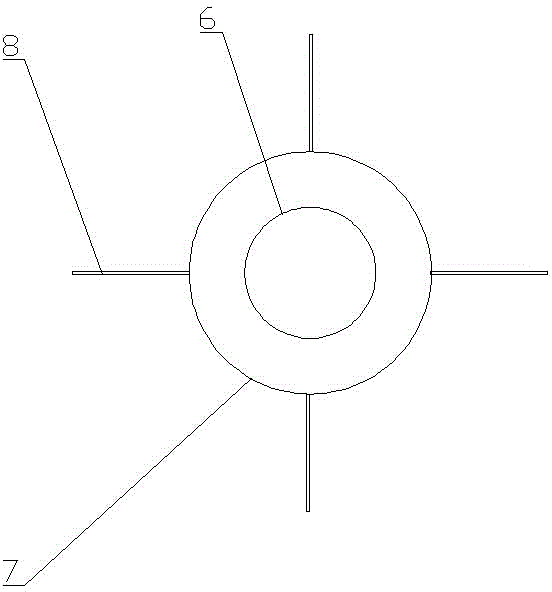

[0032] see figure 1 and figure 2 The graded filtration pre-ash barrel of the present invention comprises a barrel body 1 and an agitator 2 arranged on the barrel body, a cane juice inlet 3, a lime milk inlet 4, and a discharge port 5; a pre-ash juice solid-liquid separation device is arranged under the barrel body , the solid-liquid separation device is divided into 2-4 layers of filter mechanisms, each layer of filter mechanism includes a filter screen frame 7, a filter channel 9; Vertically arranged in the filter channel 9, the filter channel at the inner bottom is provided with a separation liquid outlet 10, and the upper and lower layers of filter channels 9 are connected by the separation liquid outlet 10; the filter screen frame 7 can rotate freely around the support shaft.

[0033] The grid size of the uppermost filter screen frame 7 matches the average size of the pre-lime juice floc; the grid size of each layer of filter screen frame 7 decreases layer by layer with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com