Tool Electrode Low Frequency Vibration Electrolytic Machining Device

A tool electrode, low-frequency vibration technology, applied in electric machining equipment, electrochemical machining equipment, accessories and other directions, can solve problems such as difficult adjustment, achieve good replaceability, simple and convenient machining process, improve machining accuracy and machining stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

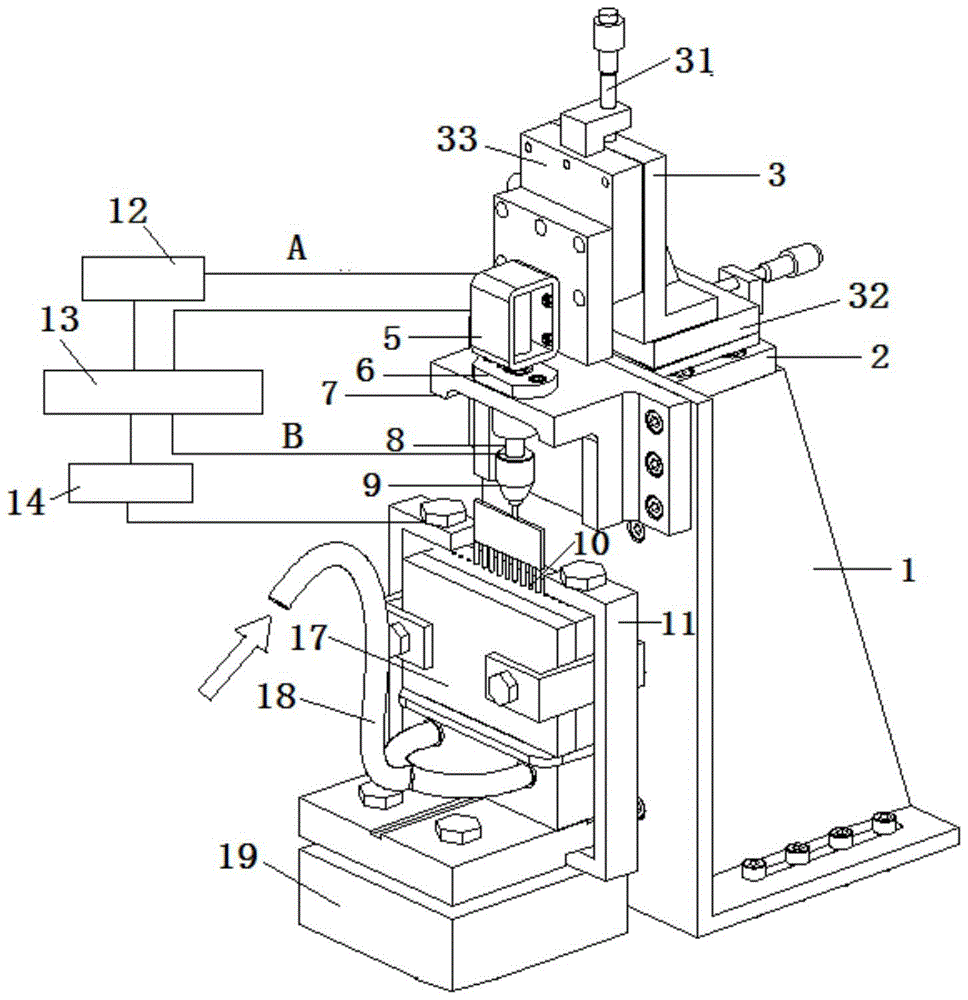

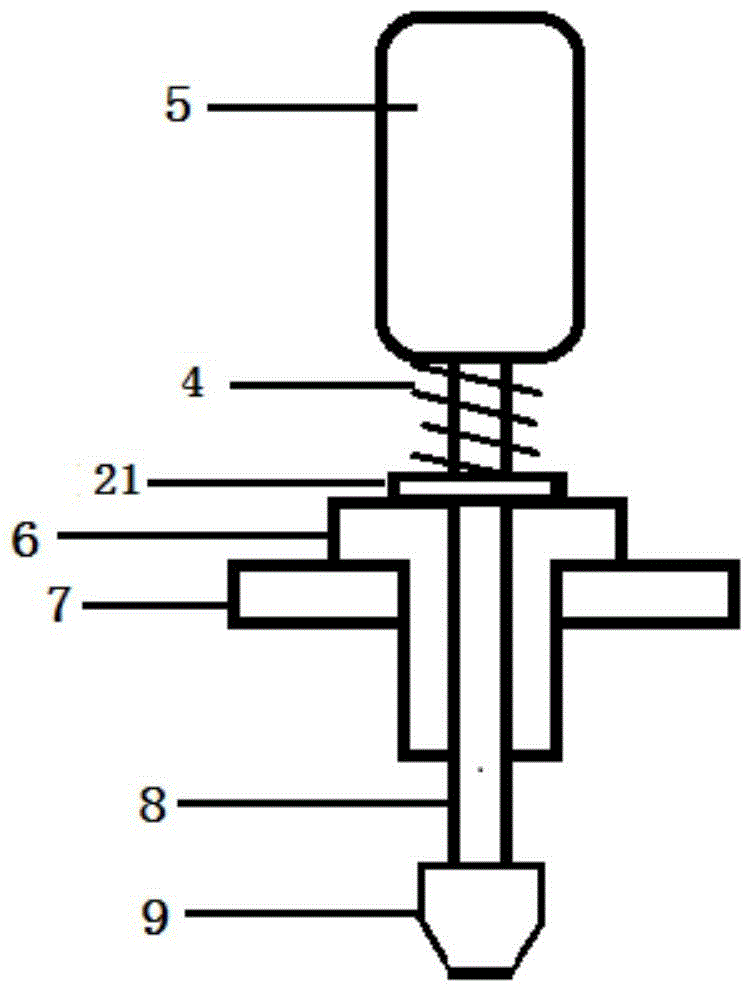

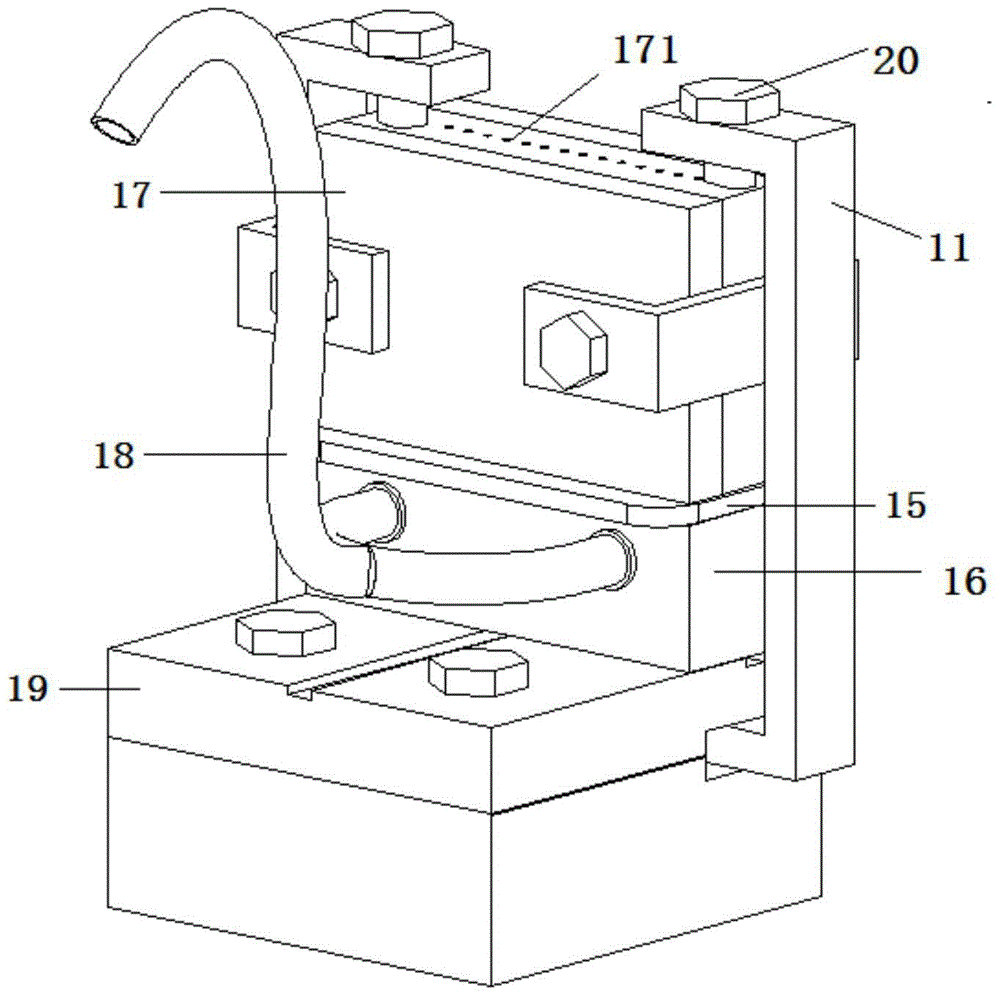

[0023] Referring to the accompanying drawings, the tool electrode low-frequency vibration electrolytic machining device includes a fixing device for fixing the workpiece 17, a through hole 171 is opened on the top surface of the workpiece 17, and a tool electrode 10 is arranged directly above the through hole 171, The tool electrode is aligned with the through hole, and the tool electrode 10 that can move up and down along the through hole 171 is arranged on an adjustment frame, and the adjustment frame is provided with a drive for driving the tool electrode 10 to move up and down. device,

[0024] Described adjusting frame comprises base 1 and displacement platform 3, and the horizontal adjustment plate 32 of described displacement platform 3 is horizontally arranged on the base through connection plate 32, and the vertical adjustment plate 33 of described displacement platform 3 links to each other with driving device through connection plate ;

[0025] Described driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com