Dissolved air flotation sewage processing device with self-cleaning function

A sewage treatment device and dissolved air flotation technology, applied in the direction of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the complexity and cost of equipment and prolonging the effective Problems such as running time and failure to completely solve the problem have achieved the effect of commercial promotion, stable water quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

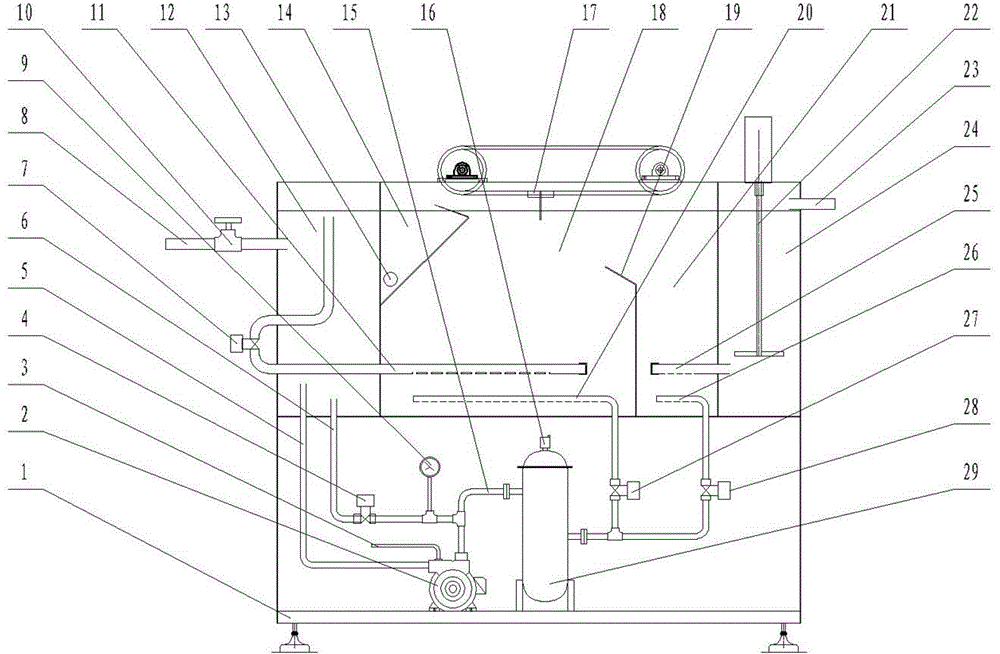

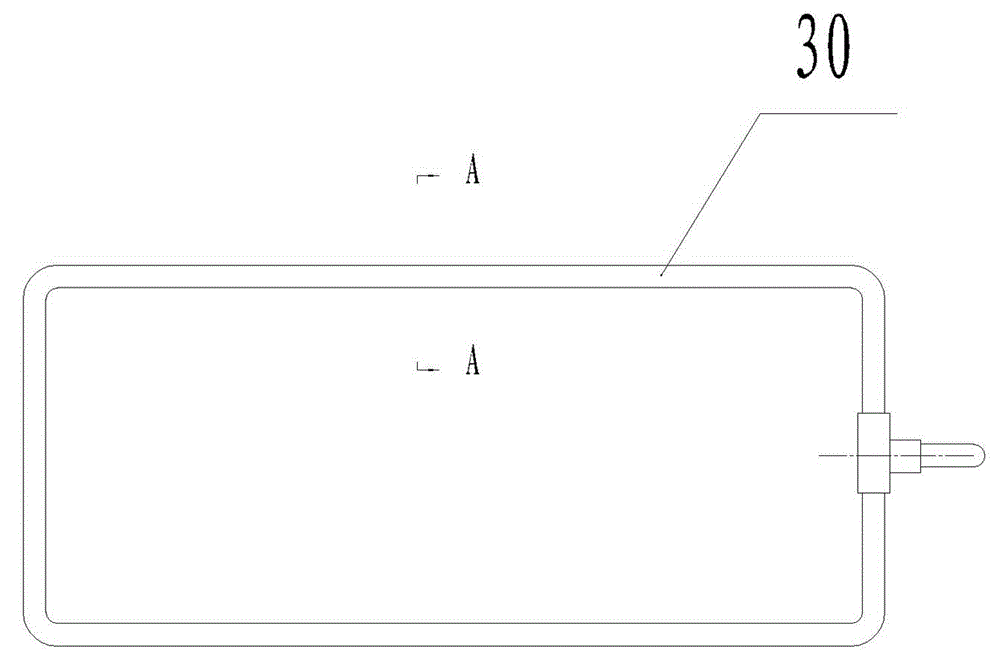

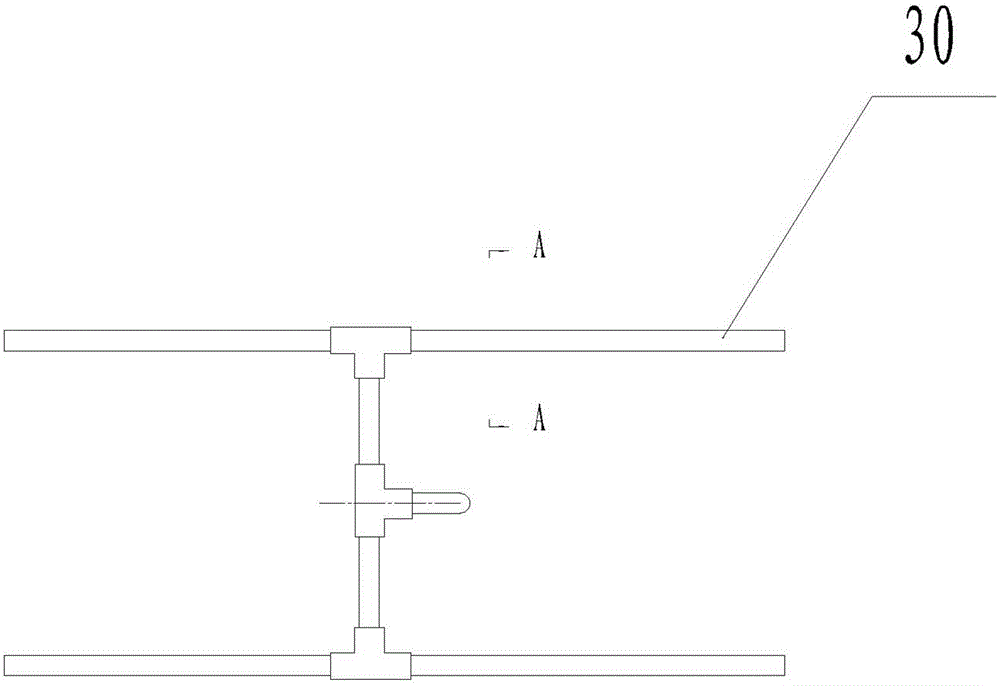

[0024] The present invention is a dissolved air flotation sewage treatment device with self-cleaning function, comprising a base frame 1, a coagulation reaction zone 24, a dissolved air pump 2 arranged on the base frame in sequence, a gas-liquid separation tank 29, and a contact reaction zone 21 , scum separation zone 18, scum scraping device 17, clear water zone 12, the interconnection relation of each part is: coagulation reaction zone 24 inside is provided with agitator 22 and sewage inlet pipe 23 is set at appropriate position; Contact reaction zone 21 and scum The lower part of the separation area 18 is separated by a deflector 19, and the upper part is connected. The upper part of the communication is equipped with a scum scraping device 17. Along the moving direction of the scum scraping device, a scum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com