Preparation method and application of aquilaria wood hydrolat

A pure dew, agarwood technology, applied in the application, essential oil/spice, fat production, etc., can solve the problems of difficulty in exerting the skin care effect of characteristic spice plants, low content of effective substances, etc., and achieve rich and coordinated smoke and high content of effective substances. , The effect of masking the improvement of miscellaneous air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

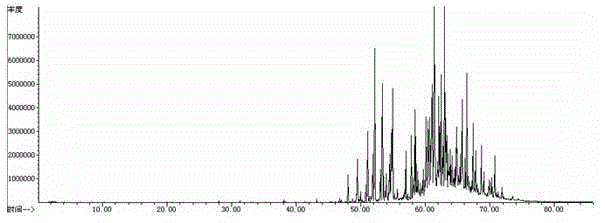

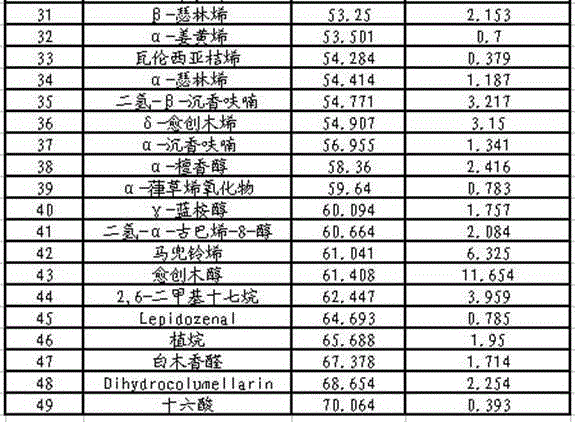

Image

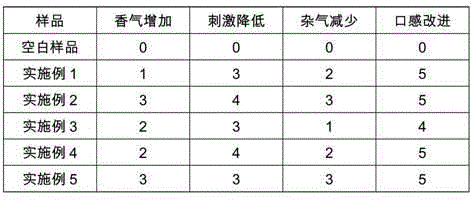

Examples

Embodiment 1

[0034] Weigh 20kg of Acacia heartwood and pulverize it, pass through a 20-mesh sieve to obtain Agarwood powder, add 160kg of deionized water and stir to form a suspension, then add 0.2kg of sucrose ester, and use a flash extractor to perform mechanical crushing for 5 minutes. The mixed liquid is then centrifuged at 5000rpm in a continuous feeding and discharging mode to collect the centrifugate; the centrifuge is passed through a multi-layer cross-flow packing rotary aroma extraction device for aromatherapy, wherein the feed temperature is 70°C, the internal temperature of the distillation tower is 85°C, and the first-stage condensation The water inlet temperature is 25°C, and the secondary condensate inlet temperature is -5°C. After collecting about 50kg of the secondary condensate, stop collecting, and the obtained condensate is agarwood hydrosol. The pure dew prepared in this embodiment has a pure and rich aroma, and the smell is soothing and calming. It has the effects of ...

Embodiment 2

[0036]Weigh 20kg of Acacia heartwood and pulverize it, pass through a 30-mesh sieve to obtain Agarwood powder, add 200kg of deionized water and stir to form a suspension, then add 0.66kg of sucrose ester, and use a flash extractor to perform mechanical crushing for 8 minutes. The mixture is then centrifuged at 4500rpm in a continuous feed-in and out-feed mode to collect the centrifugate; the centrifuge is passed through a multi-layer cross-flow packing rotary aroma extraction device for aromatherapy, wherein the feed temperature is 80°C, the internal temperature of the distillation tower is 90°C, and the first-stage condensation The water inlet temperature is 30°C, and the secondary condensed water inlet temperature is 0°C. After collecting about 50kg of the secondary condensate, stop collecting, and the obtained condensate is agarwood hydrosol. The pure dew prepared in this embodiment has a pure and strong aroma, and the smell is soothing and sedative. It has the effects of s...

Embodiment 3

[0038] Weigh 20kg of Acacia heartwood and crush it, pass it through a 40-mesh sieve to obtain Agarwood powder, add 100kg of deionized water and stir to form a suspension, then add 0.12kg of Tween 60, and use a flash extractor for mechanical crushing for 5 minutes , the mixed liquid is then centrifuged in a continuous feeding and discharging mode at 4000rpm to collect the centrifuged liquid; the centrifuged liquid is passed through a multi-layer cross-flow packing rotary aroma extraction device for aromatherapy, wherein the feed temperature is 75°C, and the internal temperature of the distillation tower is 90°C. The inlet temperature of the condensed water is 35°C, and the inlet temperature of the secondary condensed water is -3°C. After collecting about 50kg of the secondary condensate, the collection is stopped, and the obtained condensate is agarwood hydrosol. The pure dew prepared in this embodiment has a pure and strong aroma, and the smell makes people feel happy and calm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com