High yielding cellulase engineering bacterium and application thereof

A technology of cellulase and engineering bacteria, applied in the directions of enzymes, enzymes, fungi, etc., can solve the problems of low cellulase yield, unsuitable for large-scale production and use, etc., and achieve the effect of improving enzyme activity and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

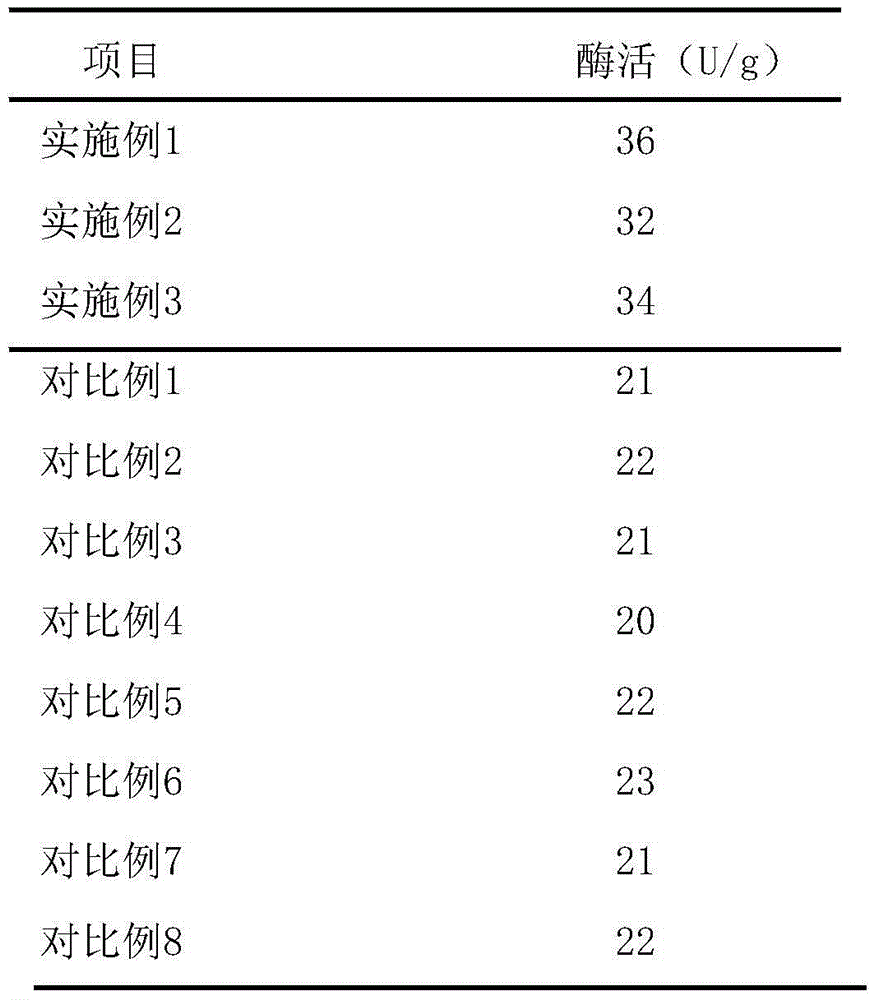

Examples

Embodiment 1-3

[0020] Embodiments 1-3 of the present invention relate to the construction of a high-yielding cellulase engineering bacterium, all consisting of the following steps:

[0021] A. Construction of Amylase Gene Knockout Plasmid

[0022] (1) Synthesis of recombinant fragments

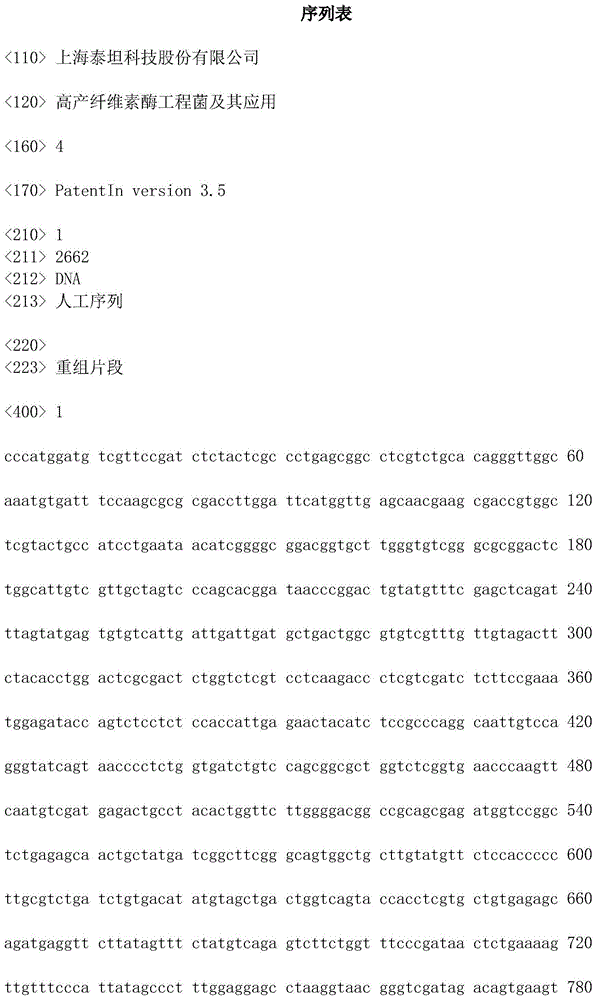

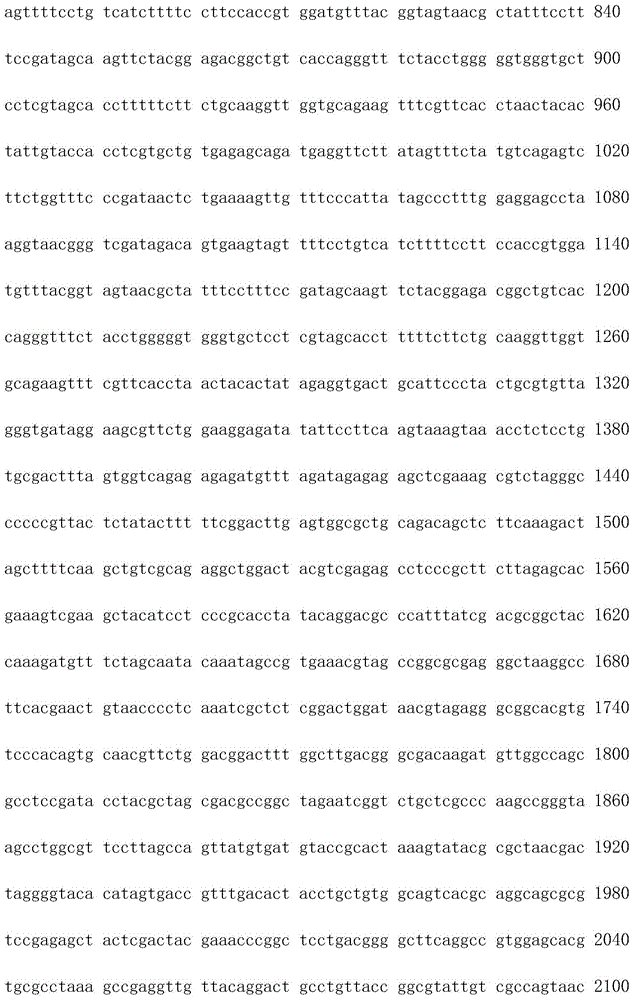

[0023] The recombinant fragment consists of the first half of the amylase gene (SEQ ID NO.2), the hygromycin B resistance gene expression unit (SEQ ID NO.3), and the second half of the amylase gene (SEQ ID NO.4). The recombinant fragment (SEQ ID NO.1) was digested with 2 μL of NcoI enzyme solution (purchased from TakaRa) at a certain temperature for 16 hours;

[0024] (2) Extraction and digestion of pCAMBIA1300

[0025] Escherichia coli E.coli DH5α containing the pCAMBIA1300 plasmid was shaken and cultured at 37°C for 12 hours; 1.5 mL of the bacteria was placed in an EP tube, centrifuged at 4000 rpm for 3 min, and the supernatant was discarded; 0.1 mL of solution I (1% glucose, 50 mM EDTA pH 8.0, 25mM Tri...

Embodiment 1

[0061] As mentioned above, the synthesized recombinant fragment was digested with 2 μL of NcoI enzyme solution at 32.8° C. for 16 hours.

Embodiment 2

[0063] As mentioned above, the synthesized recombinant fragment was digested with 2 μL of NcoI enzyme solution at 32.3° C. for 16 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com