A kind of preparation method of cationic synthetic vegetable oil fatliquor

A technology for vegetable oil and fatliquor, which is applied in the preparation of organic compounds, the preparation of carboxylic acid amides, chemical instruments and methods, etc., can solve the problems of few varieties of internal emulsification type cationic fatliquor and can not meet the actual needs of production, etc. Achieve excellent dilution stability, enhanced hand and softness, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

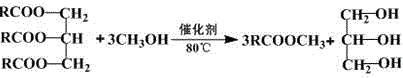

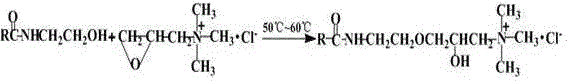

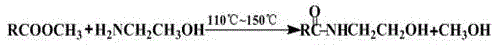

[0025] 1. Transesterification reaction: Add 500 parts of rapeseed oil and 90 parts of methanol into a 1000 mL four-necked flask equipped with a thermometer, a stirring device and a reflux condenser, raise the temperature to 80°C, add 5 parts of p-toluenesulfonic acid, and keep stirring to react 4 hours, after the completion of the reaction, the product was allowed to stand for stratification, the upper strata was rapeseed oil fatty acid methyl ester, and the lower floor was glycerol, and the lower floor was released to obtain rapeseed oil fatty acid methyl ester; Add 200 parts of rapeseed oil fatty acid methyl ester and 50 parts of ethanolamine to a 500 mL four-necked flask with a stirring device and a reflux condenser, raise the temperature to 140°C, and react at 0.04Mpa for 3 hours; 3. Quaternization reaction: cool down to 55°C , add 1.25 parts of triethylamine, take 122 parts of glycidyltrimethylammonium chloride aqueous solution dropwise into the reaction kettle, keep stirr...

Embodiment 2

[0027] 1. Transesterification reaction: Add 500 parts of rapeseed oil and 90 parts of methanol into a 1000 mL four-necked bottle equipped with a thermometer, a stirring device and a reflux condenser, raise the temperature to 80°C, add 5 parts of p-toluenesulfonic acid, and keep stirring to react 3.5 hours, after the completion of the reaction, the product was allowed to stand for stratification, the upper layer was rapeseed fatty acid methyl ester, the lower floor was glycerol, and the lower floor was released to obtain rapeseed fatty acid methyl ester; Add 200 parts of rapeseed oil fatty acid methyl ester and 80 parts of ethanolamine to a 500 mL four-necked flask with a stirring device and a reflux condenser, raise the temperature to 135°C, and react at 0.04Mpa for 3 hours; 3. Quaternization reaction: cool down to 55°C , add 1.25 parts of triethylamine, take 122 parts of glycidyltrimethylammonium chloride aqueous solution dropwise into the reaction kettle, keep stirring and re...

Embodiment 3

[0029] 1. Transesterification reaction: Add 500 parts of rapeseed oil and 90 parts of methanol into a 1000 mL four-necked flask equipped with a thermometer, a stirring device and a reflux condenser, raise the temperature to 80°C, add 5 parts of p-toluenesulfonic acid, and keep stirring to react 4 hours, after the completion of the reaction, the product was allowed to stand for stratification, the upper strata was rapeseed oil fatty acid methyl ester, and the lower floor was glycerol, and the lower floor was released to obtain rapeseed oil fatty acid methyl ester; Add 200 parts of rapeseed oil fatty acid methyl ester and 80 parts of ethanolamine to a 500 mL four-necked flask with a stirring device and a reflux condenser, raise the temperature to 145°C, and react at 0.04Mpa for 4 hours; 3. Quaternization reaction: cool down to 55°C , add 1.25 parts of triethylamine, take 122 parts of glycidyltrimethylammonium chloride aqueous solution dropwise into the reaction kettle, keep stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com