Polyethylene polypropylene fiber high polymer waterproof rolling material for improving artificial weathering aging performance

A polyethylene polypropylene fiber and polymer waterproof technology, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of high leakage rate, improve artificial weather aging indicators, reduce Production cost, effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The polyethylene polypropylene polymer waterproof membrane for improving the artificial weathering performance is composed of the following components by weight:

[0029] 92.0 parts of linear low-density polyethylene resin, 1.5 parts of titanium oxide, 0.1 parts of Span 85, and 8.0 parts of active agent;

[0030] Described activator obtains by following preparation method:

[0031] ①Steam explosion treatment: Put the residue of Luo Han Guo extracted by water into a steam explosion tank for treatment, the explosion pressure is 3.0-3.5Mpa, and the pressure holding time is maintained at 150-200s;

[0032] ②High-shear homogenizer treatment: Add the material obtained in step ① into pure water of equal weight, and process it through a high-shear homogenizer at a line speed of 30-40m / s and a time of 3-5min, and dry until the moisture content is Activator is obtained below 5%.

Embodiment 2

[0034] The polyethylene polypropylene polymer waterproof membrane for improving the artificial weathering performance is composed of the following components by weight:

[0035] 93.0 parts of linear low-density polyethylene resin, 0.5 parts of titanium oxide, 0.5 parts of Span 85, and 7.0 parts of active agent;

[0036] Described activator obtains by following preparation method:

[0037] ①Steam explosion treatment: Put the residue of Luo Han Guo extracted by water into a steam explosion tank for treatment, the explosion pressure is 3.0-3.5Mpa, and the pressure holding time is maintained at 150-200s;

[0038] ②High-shear homogenizer treatment: Add the material obtained in step ① into pure water of equal weight, and process it through a high-shear homogenizer at a line speed of 30-40m / s and a time of 3-5min, and dry until the moisture content is Activator is obtained below 5%.

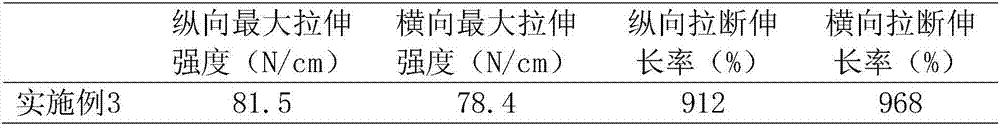

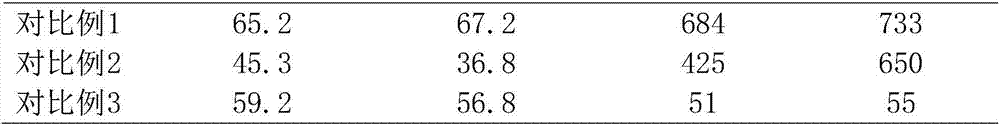

Embodiment 3

[0040] The polyethylene polypropylene polymer waterproof membrane for improving the artificial weathering performance is composed of the following components by weight:

[0041] 95.0 parts of linear low-density polyethylene resin, 1.0 parts of titanium oxide, 0.3 parts of Span 85, and 5.0 parts of active agent;

[0042] Described activator obtains by following preparation method:

[0043] ①Steam explosion treatment: Put the residue of Luo Han Guo extracted by water into a steam explosion tank for treatment, the explosion pressure is 3.0-3.5Mpa, and the pressure holding time is maintained at 150-200s;

[0044] ②High-shear homogenizer treatment: Add the material obtained in step ① into pure water of equal weight, and process it through a high-shear homogenizer at a line speed of 30-40m / s and a time of 3-5min, and dry until the moisture content is Activator is obtained below 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com