Method and system for supplying power to equipment using thermoelectric generation of pipelines

A technology of thermoelectric power generation and thermoelectric power generation sheet, which is applied in the directions of generators/motors, battery circuit devices, current collectors, etc., can solve problems such as difficulty in making full use of fluid temperature, poor soil thermal conductivity, and disappearance of temperature difference between hot and cold surfaces of power generation sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

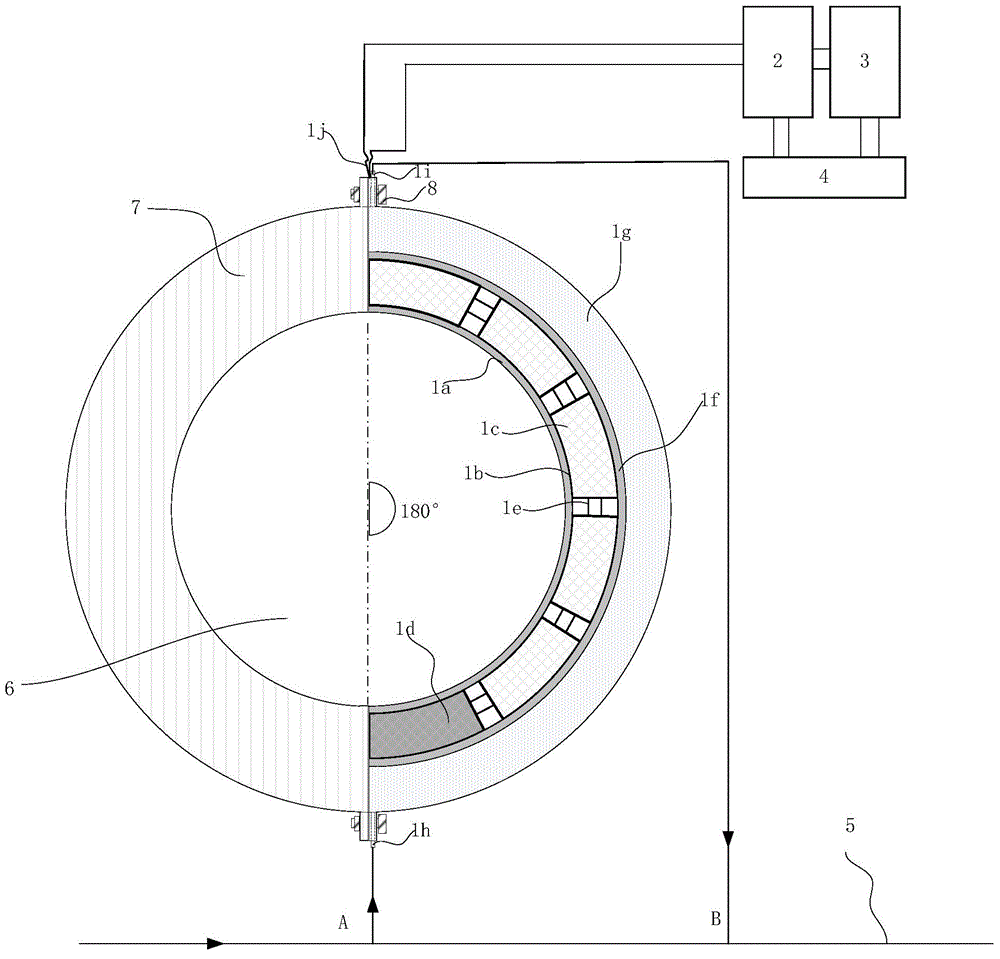

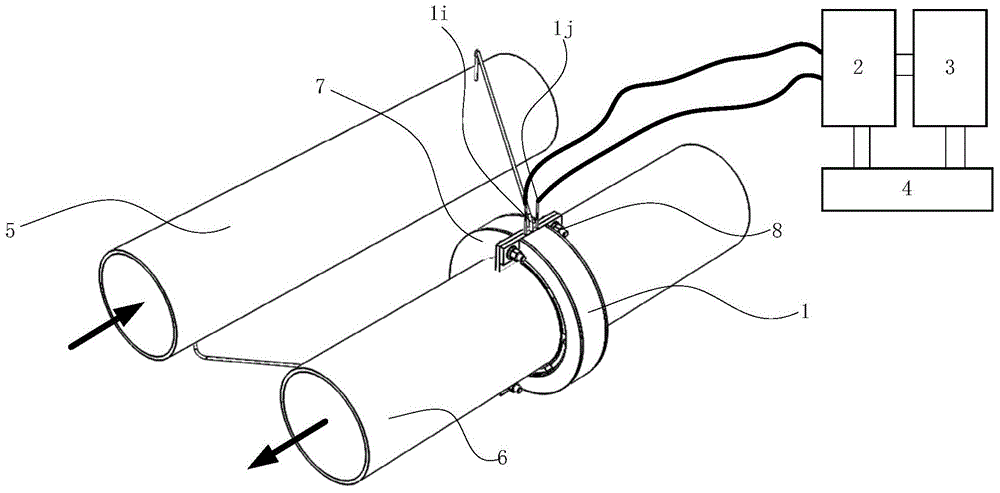

[0066] see figure 1 , figure 2 , image 3 .

[0067] A system for supplying power to equipment using temperature difference power generation in pipelines, comprising a temperature difference power generation system 1, a control circuit 2, an electrical storage device 3, equipment requiring power supply 4, a first pipeline 5 and a second pipeline 6, a fastening dual ring 7, and a tight 8 solid bolts are formed.

[0068] The thermoelectric power generation system 1 consists of an inner layer of compact heat-conducting material layer 1a, a thermoelectric chip arrangement chamber 1b, a thermoelectric chip group 1c, a pseudo-thermoelectric chip group 1d, an internal connection electrode 1e of the power chip, a middle compact thermal conductive material layer 1f, and a fluid The circulation chamber 1g, the inlet 1h of the fluid circulation chamber, the outlet 1i of the fluid circulation chamber, and the electric energy output electrode 1j of the thermoelectric generation sheet g...

Embodiment 2

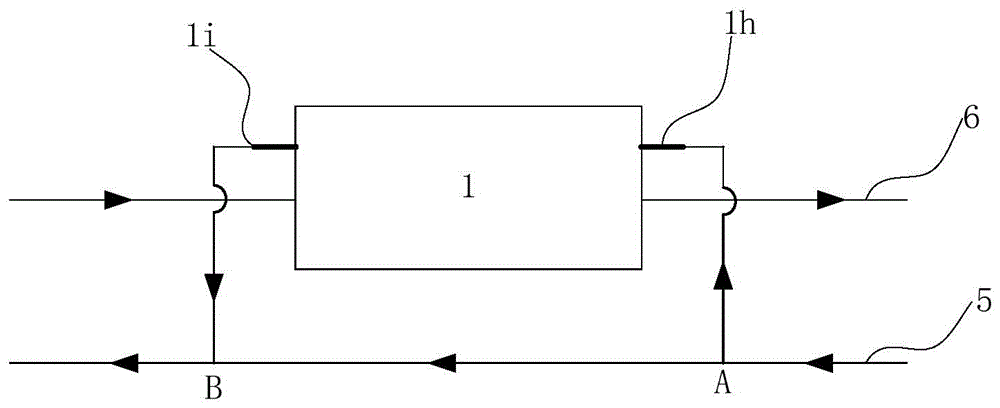

[0073] see Figure 4 with Figure 5 .

[0074] A system that utilizes fluid temperature difference power generation to supply power to equipment, including a temperature difference power generation system 1, a control circuit 2, an electrical storage device 3, equipment requiring power supply 4, a first pipeline 5 and a second pipeline 6, a fastening dual ring 7, and a tight 8 solid bolts are formed.

[0075]The thermoelectric power generation system 1 consists of an inner layer of compact heat-conducting material layer 1a, a thermoelectric chip arrangement chamber 1b, a thermoelectric chip group 1c, a pseudo-thermoelectric chip group 1d, an internal connection electrode 1e of the power chip, a middle compact thermal conductive material layer 1f, and a fluid The circulation chamber 1g, the inlet 1h of the fluid circulation chamber, the outlet 1i of the fluid circulation chamber, and the electric energy output electrode 1j of the thermoelectric generation sheet group. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com