Ag-In alloy sputtering target

A sputtering target and ag-in technology, which is applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problem of reduced reflectivity of Ag alloy reflective film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

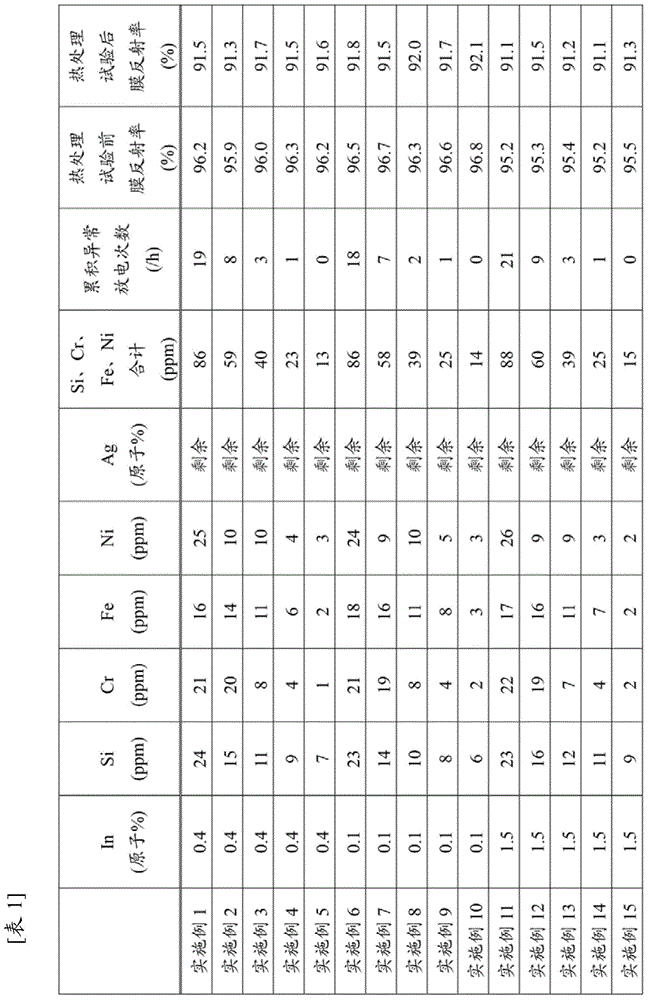

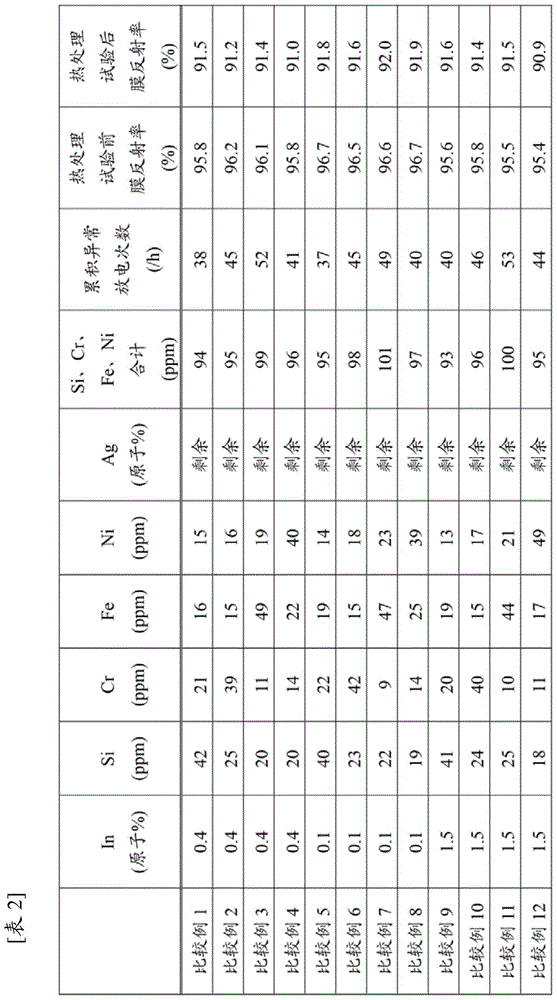

[0037] First, in order to manufacture the Ag-In alloy sputtering target which concerns on 1st Embodiment of this invention, Ag of purity 99.9 mass % (3N) or more is prepared as a raw material. With regard to the Ag raw material, the above-mentioned purification method is carried out, and the content of Si, Cr, Fe, and Ni is all 30 ppm or less with respect to the formed Ag-In alloy sputtering target, and the total content is only 90 ppm or less. Ag raw materials of Si, Cr, Fe and Ni. The selected Ag raw material and the In raw material having a purity of 99.99% by mass or higher are weighed so as to have a predetermined composition.

[0038] Next, the above-mentioned Ag raw material is melted in a high vacuum or an inert gas atmosphere, and a predetermined content of In raw material is added to the obtained molten metal. Thereafter, melting is carried out in a high vacuum or an inert gas atmosphere to produce a molten cast ingot of an Ag alloy containing a predetermined atomic...

no. 2 Embodiment approach 〕

[0048] Next, the case of manufacturing the Ag-In alloy sputtering target of 2nd Embodiment of this invention is demonstrated below.

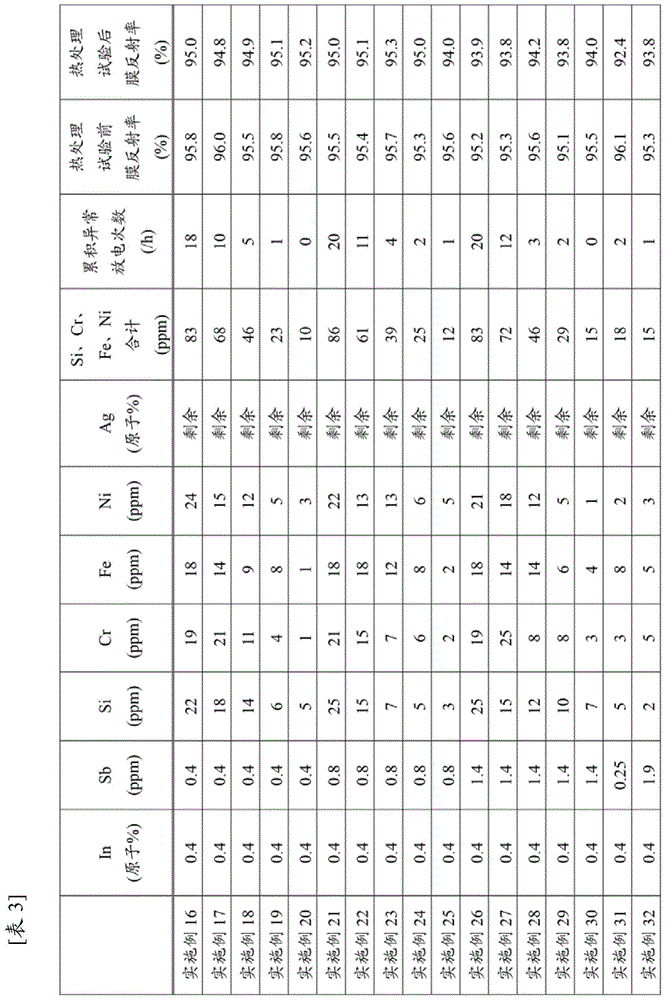

[0049] As in the case of the first embodiment, Ag with a purity of 99.9% by mass (3N) or higher is prepared as a raw material for target production, and the above-mentioned purification method is performed on this Ag raw material, and the Ag-In alloy that is formed is selected. The sputtering target contains an Ag raw material whose Si, Cr, Fe, and Ni contents are all 30 ppm or less, and whose total content is 90 ppm or less. The selected Ag raw material and the In raw material and the Sb raw material having a purity of 99.99% by mass or more are weighed so as to have a predetermined composition.

[0050] Next, the above-mentioned Ag raw material is melted in a high vacuum or an inert gas atmosphere, and predetermined contents of the In raw material and the Sb raw material are added to the obtained molten metal. Thereafter, melting is carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com