Flue-cured tobacco transplanting machine under film

A technology of transplanting machine and flue-cured tobacco, which is applied in the direction of transplanting machinery, application, agriculture, etc., to achieve the effects of high survival rate, favorable planting and growth, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

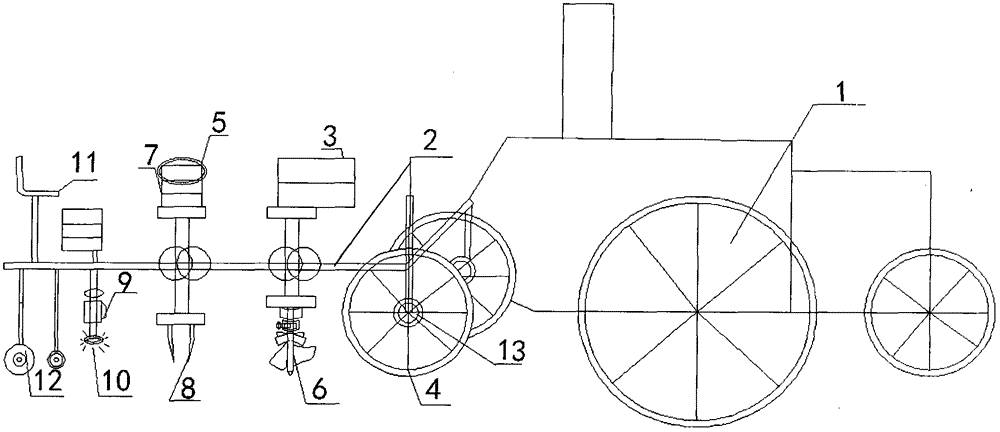

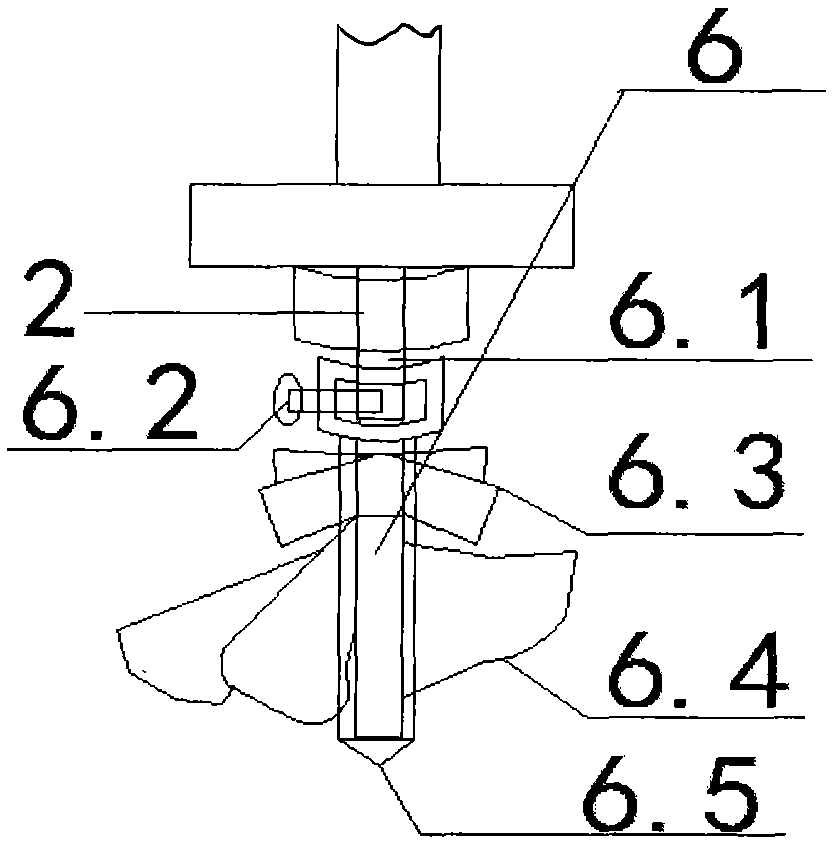

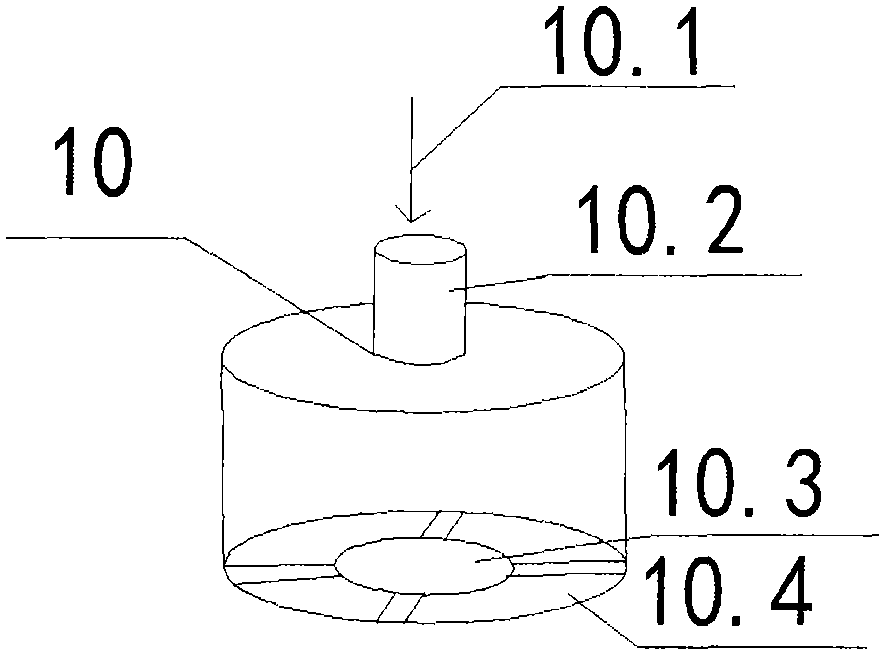

[0021] Such as figure 1 Shown, the flue-cured tobacco transplanting machine under the film of the present invention design mainly is by traction power unit, frame, ground wheel before and after, seedling frame, double crankshaft transmission device, fertilizer agitator, planter and water flow diffuser, power traction adopts The traction tractor 1 with more than 304 power, the front ground wheel 4 and the rear ground wheel 12 are transmission connected with the double crankshaft transmission, so as to realize the up and down circuitous movement of the double crankshaft; 5 to operate, the rear ground wheel 12 can adjust its height up and down according to the height of the ridge to ensure that the depth of the planing hole is suitable. The double crankshaft transmission installed between the front and rear ground wheels and along the length of the fuselage is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com