Multi-burner OVD (outside vapour deposition) preparation device of soot optical fiber preforms

A technology of optical fiber preform and loose body, which is applied in the field of optical fiber preform OVD deposition preparation equipment, can solve the problems of low deposition rate and efficiency, and achieve the effects of improving deposition rate and efficiency, good uniformity, and ensuring singleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

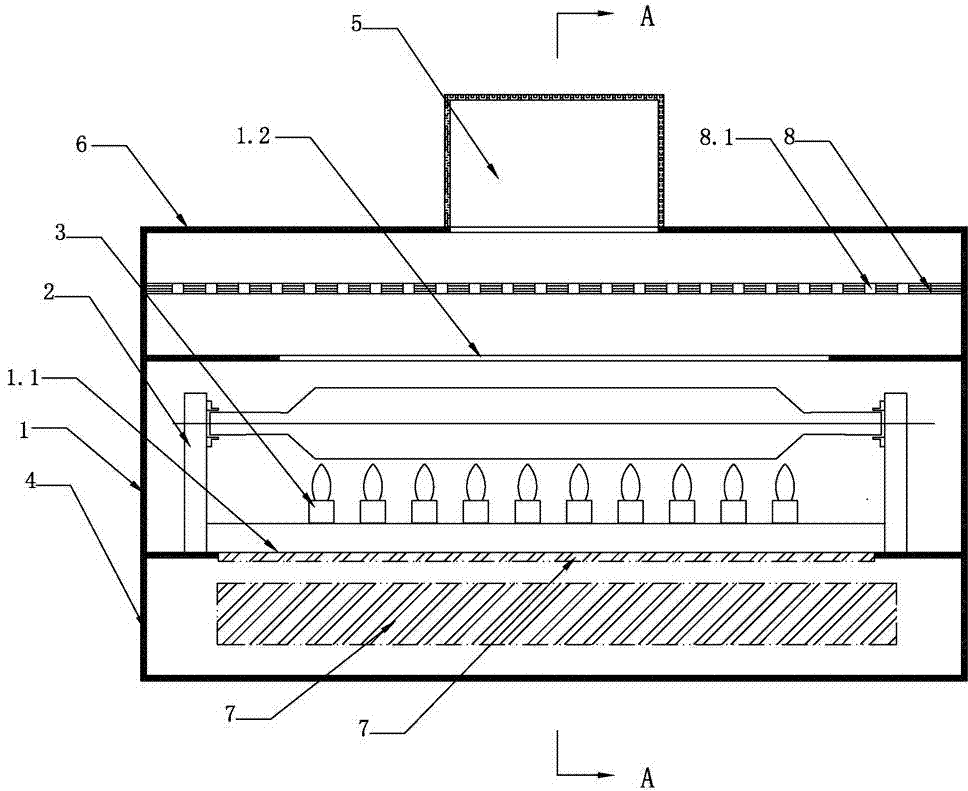

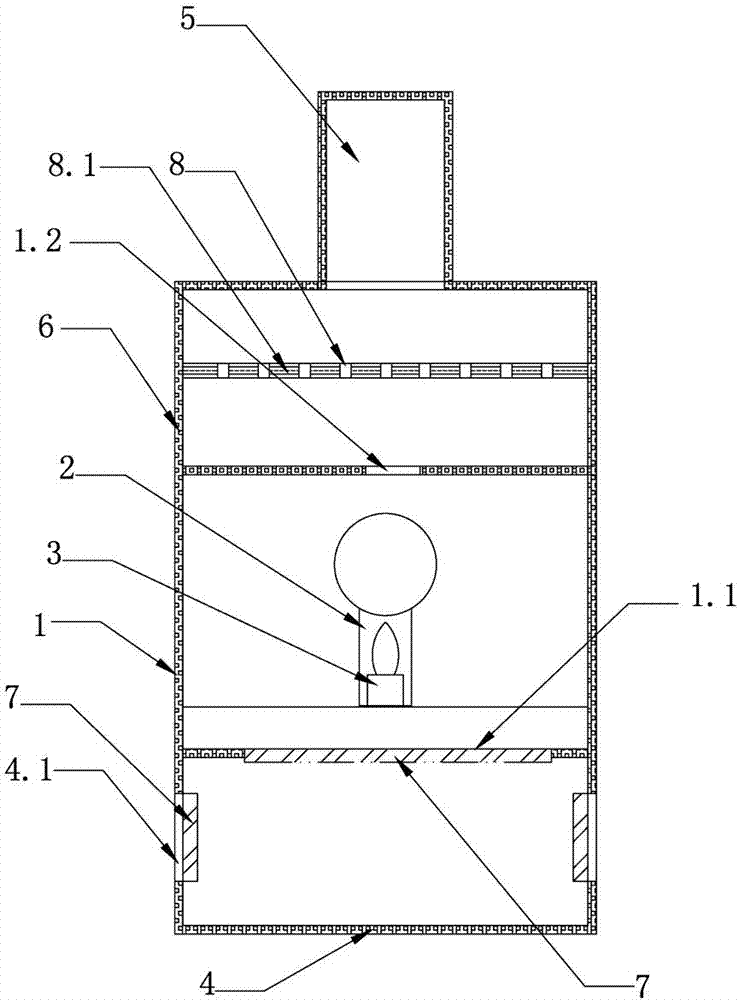

[0010] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

[0011] Such as figure 1 and figure 2 As shown, the soot optical fiber preform OVD deposition preparation device with multiple blowtorches includes a deposition box 1, an optical fiber preform deposition support 2, a blowtorch 3, a blower box 4 and an exhaust pipe 5; on the side of the blower box 4 There is an air supply hole 4.1; the air supply box 4 is set under the deposition box 1, and the optical fiber preform deposition support 2 is set in the deposition box 1; it is characterized in that it also includes a draft box 6, a filter screen 7 and a draft diffuser Laminar flow plate 8; 5 to 15 blowtorches 3 are equidistantly arranged on the optical fiber preform deposition support 2; a number of equidistant ventilation holes 8.1 are provided on the draft and diffuse flow laminar flow plate 8; on the optical fiber preform deposition support 2 The deposition b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com