Intelligent concrete crack self repairing material preparation method

A self-healing material and concrete technology, which is applied in the field of preparing intelligent concrete crack self-healing materials, can solve the problems of insufficient crack repair, difficult construction, short shelf life, etc., to achieve good repair of micro-cracks, make up for difficult construction, and easy to use The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

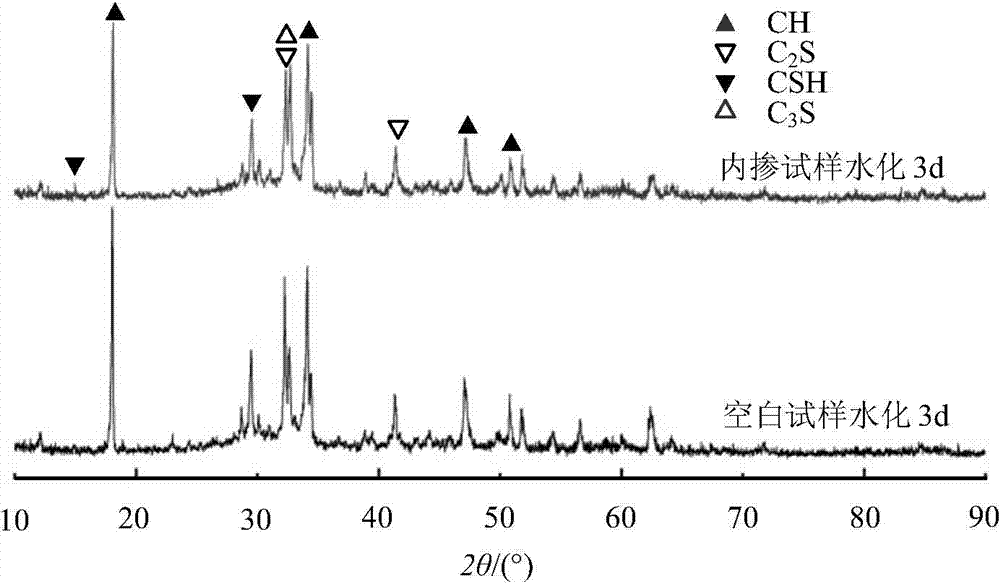

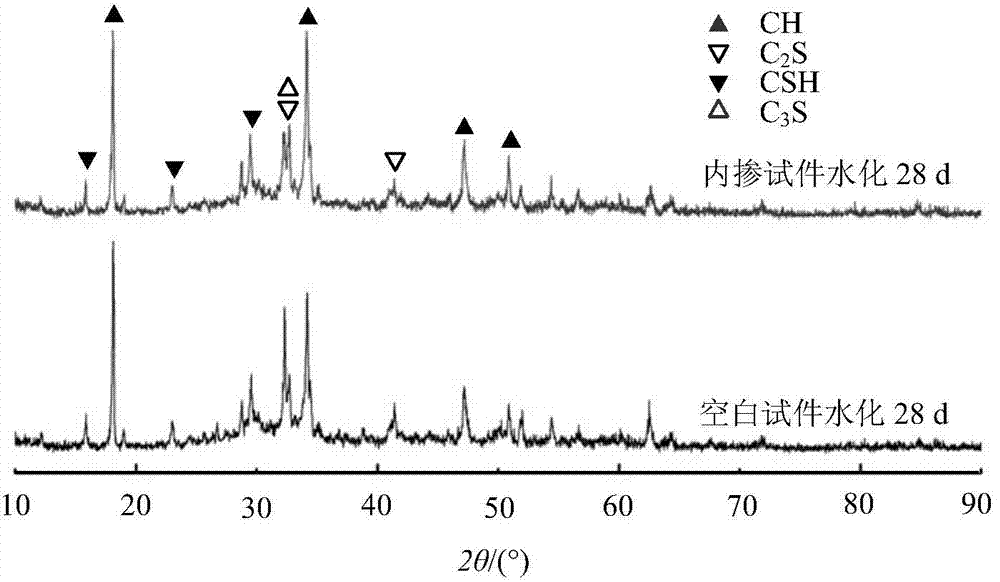

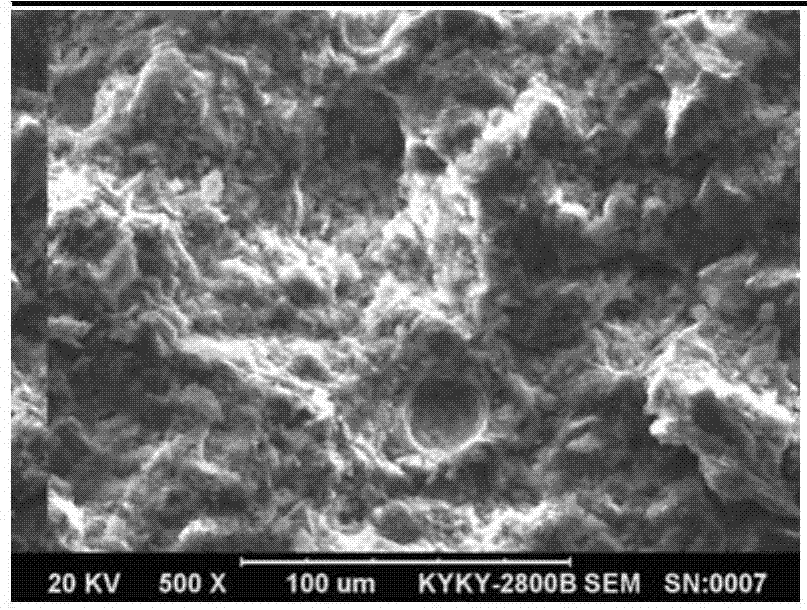

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: sodium citrate is 40%, choline chloride is 18%, KAl(SO 4 ) 2 12H 2 O is 15%, Na 2 SiO 3 9H 2 O is 15%, Ca(OH) 2 15%. In this test, a plastic plate with a thickness of 0.2mm is used to make reserved cracks, the crack length is 100mm, width is 0.2mm, and depth is 50mm. The self-repairing material content is 0%, the 28d compressive strength of ordinary concrete specimens is 39.2MPa, the self-repairing material content is 0.5%, and the 28d compressive strength of ordinary concrete specimens is 42.9MPa. The self-repairing material content is 0%, the 28d compressive strength of the reserved joint concrete specimen is 35.9MPa, the self-repairing material content is 0.5%, and the 28d compressive strength of the reserved joint concrete specimen is 36.2MPa.

Embodiment 2

[0029] Embodiment 2: sodium citrate is 40%, choline chloride is 18%, KAl(SO 4 ) 2 12H 2 O is 12%, Na 2 SiO 3 9H 2 O is 15%, Ca(OH) 2 15%. In this test, a plastic plate with a thickness of 0.2mm is used to make reserved cracks, the crack length is 100mm, width is 0.2mm, and depth is 50mm. The self-repairing material content is 0%, the 28d compressive strength of ordinary concrete specimens is 39.2MPa, the self-repairing material content is 1%, and the 28d compressive strength of ordinary concrete specimens is 45.2MPa. The self-repairing material content is 0%, the 28d compressive strength of the reserved joint concrete specimen is 35.9MPa, the self-repairing material content is 1%, and the 28d reserved joint concrete specimen's compressive strength is 40.5MPa.

Embodiment 3

[0030] Embodiment 3: sodium citrate is 40%, choline chloride is 18%, KAl(SO 4 ) 2 12H 2 O is 12%, Na 2 SiO 3 9H 2 O is 15%, Ca(OH)2 15%. In this test, a plastic plate with a thickness of 0.2mm is used to make reserved cracks, the crack length is 100mm, width is 0.2mm, and depth is 50mm. The self-repairing material content is 0%, the 28d compressive strength of ordinary concrete specimens is 39.2MPa, the self-repairing material content is 1.5%, and the 28d compressive strength of ordinary concrete specimens is 49.2MPa. The amount of self-repairing material is 0%, the 28d compressive strength of the reserved joint concrete specimen is 35.9MPa, the self-repairing material content is 1.5%, and the 28d compressive strength of the reserved joint concrete specimen is 44.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com