Stearic acid alkylolamide for leather fat-liquoring agent intermediate and method for preparing stearic acid alkylolamide

A technology of fatty acid alkyl alcohol amide and hydroxystearic acid diethanolamide, which is applied in the directions of leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. It can solve the problems of esters affecting performance, high iodine value, and limited application scope, and achieve the effect of strong light resistance and good affinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

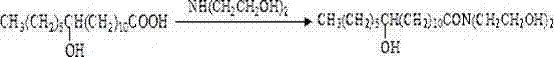

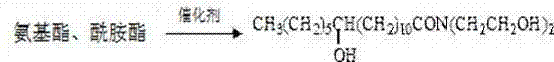

Method used

Image

Examples

Embodiment 1

[0031] 1) Weigh 100 parts of 12-hydroxystearic acid, 30 parts of diethanolamine and 2.5 parts of sodium ethoxide ethanol solution with a mass concentration of 20% in parts by mass;

[0032] 2) Add 12-hydroxystearic acid into a four-necked flask, adjust the temperature of the oil bath temperature control device so that 12-hydroxystearic acid is in a molten state at 80~95°C, then add diethanolamine and raise the temperature to 135°C. Pressure distillation reaction for 4 hours; then lower the temperature to 70°C, add sodium ethoxide ethanol solution with a mass concentration of 20%, and stir for 3 hours. The temperature is lowered to 55°C, and the fatty acid alkanolamide, which is an intermediate of the fatliquoring agent, is discharged; the appearance is beige paste at room temperature, and the purity is above 90%.

Embodiment 2

[0034] 1) According to the number of parts by mass, take 100 parts of 12-hydroxystearic acid, 30 parts of diethanolamine and 3 parts of sodium ethoxide ethanol solution with a mass concentration of 20%;

[0035] 2) Add 12-hydroxystearic acid into a four-necked flask, adjust the temperature of the oil bath temperature control device so that 12-hydroxystearic acid is in a molten state at 80~95°C, then add diethanolamine and raise the temperature to 135°C. Pressure distillation reaction for 4 hours; then lower the temperature to 70°C, add sodium ethoxide ethanol solution with a mass concentration of 20%, and stir for 2.5 hours. The temperature is lowered to 55°C, and the fatty acid alkanolamide, which is an intermediate of the fatliquoring agent, is discharged; the appearance is beige paste at room temperature, and the purity is above 90%.

Embodiment 3

[0037] 1) In parts by mass, 100 parts of 12-hydroxystearic acid, 40 parts of diethanolamine and 5 parts of sodium ethoxide ethanol solution with a mass concentration of 18% were respectively taken;

[0038] 2) Add 12-hydroxystearic acid into a four-necked flask, adjust the temperature of the oil bath temperature control device so that 12-hydroxystearic acid is in a molten state at 80~95°C, then add diethanolamine and raise the temperature to 145°C. Pressure distillation reaction for 3 hours; then lower the temperature to 90°C, add sodium ethoxide ethanol solution with a mass concentration of 18%, and stir for 3 hours. The temperature is lowered to 55°C, and the fatty acid alkanolamide, which is an intermediate of the fatliquoring agent, is discharged; the appearance is beige paste at room temperature, and the purity is above 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com