Colour filter of liquid crystal display and liquid crystal display using said colour filter

A liquid crystal display and liquid crystal display technology, applied in the field of color filters, can solve problems such as weak light resistance, low heat resistance, and weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

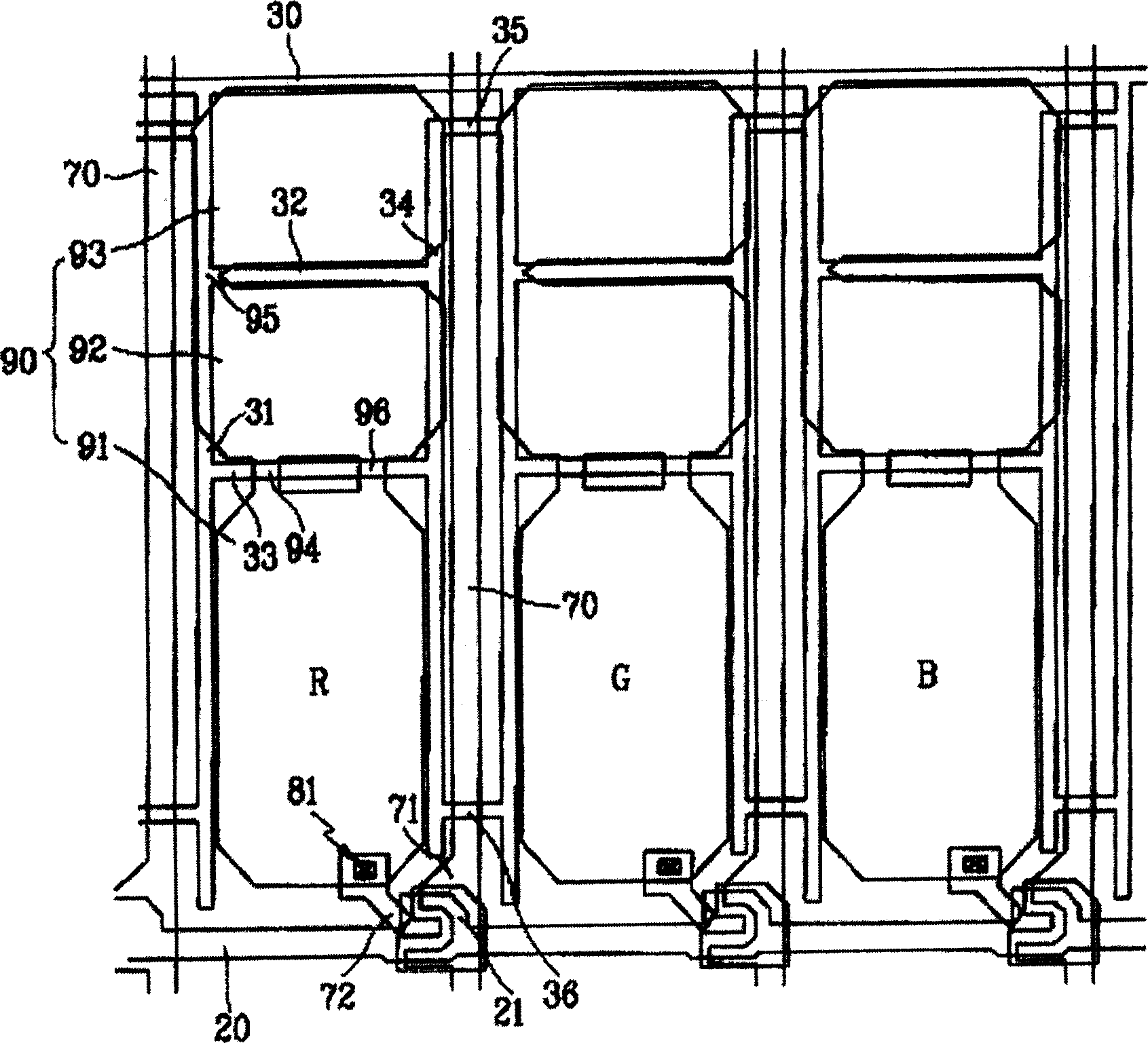

[0076] Embodiment 1-Preparation of color filter

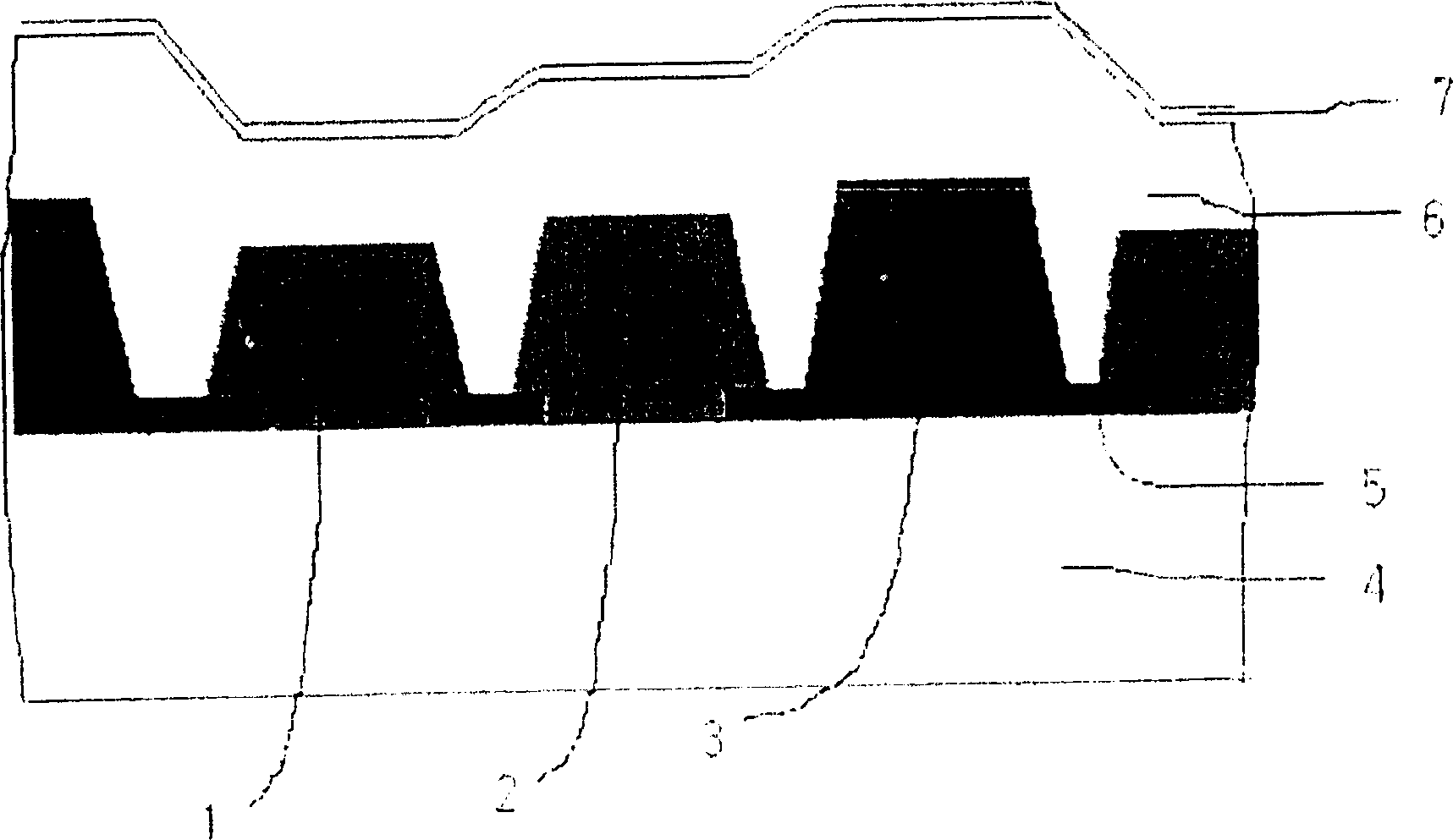

[0077] A 730 mm x 920 mm x 0.7 mm transparent glass substrate (Coming 1737) was cleaned and dried with a UV cleaning device low-pressure mercury lamp. The 1600_ thick Cr film and the 400_ thick Cr film 2 o 3 The films were sprayed continuously to obtain a Cr glass.

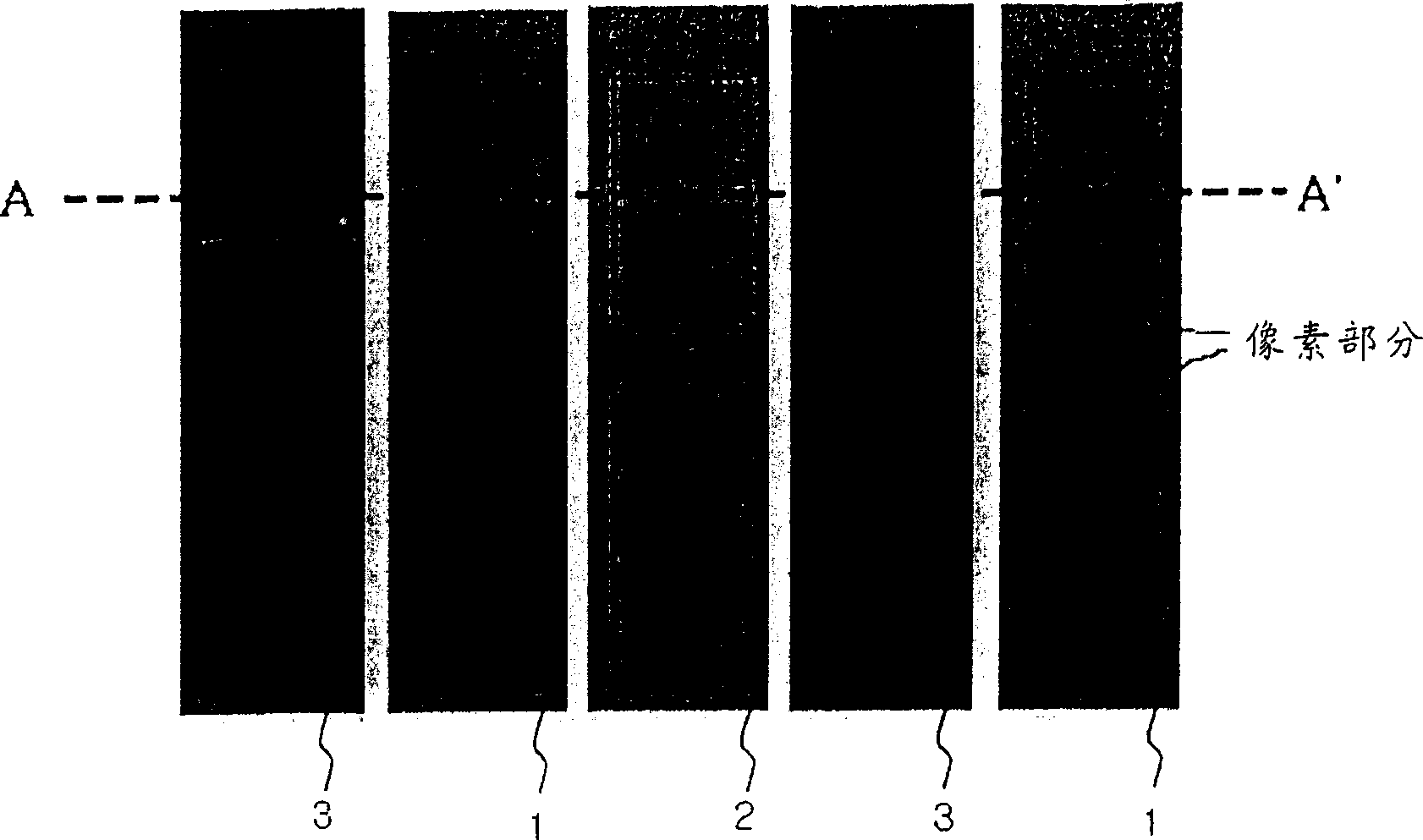

[0078] A posi-photoresist (Clariant's HKT601) with a thickness of 1.2 μm was coated on the Cr glass. After drying, use a mask with 230 μm × 60 μm openings at 50 mJ / cm 2 exposure. The exposed glass is rinsed with alkali. Then, the rinsed opening on the photoresist is etched with CAN (cerium ammonium nitrate), and the sunlight resist is stripped and cleaned to obtain a black matrix glass.

[0079] Red photoresist (Dongwoon Fine-Chem's M-R352) was coated on the prepared black matrix glass, exposed, rinsed, and baked to obtain red pixels. In the same way, green pixels were obtained with green photoresist (Dongwoon Fine-Chem's M-R302S) and blue pixels were obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com