Dacron color silk with photocatalytic degradation function and preparing method thereof

A photocatalytic, colored yarn technology, applied in the direction of melt spinning, single-component polyester rayon, textiles and papermaking, etc. The effect of promotion and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

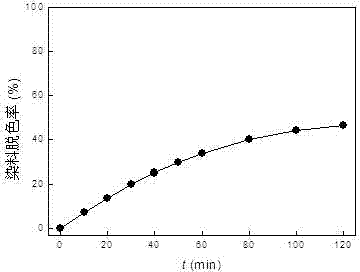

Embodiment 1

[0021] 1. Contains Nano TiO 2 Preparation of PET Masterbatch

[0022] Using blending compounding and melt kneading technology, the nano-TiO with a mass fraction of 20% 2 Particles, 0.4% tetrabutyl titanate coupling agent, 0.6% polyethylene dispersant (molecular weight 2000-4000) and 79% polyester (PET) resin are mixed evenly in a high-speed mixer, and then added to the twin-screw extrusion Melt and mix uniformly in the machine, then cool in a water bath and pelletize with a pelletizer, and finally dry in a vacuum to obtain nano-TiO 2 PET masterbatch.

[0023] 2. Nano-TiO 2 -Preparation of PET color yarn

[0024] The mass fraction of 5% containing nano-TiO 2 PET masterbatch, 5% color masterbatch and 90% conventional PET chips are mixed and melt-spun, and then stretched on a stretching machine to obtain nano-TiO 2 -PET colored yarn. Main spinning process: spinning temperature: 275°C, spinning speed: 800m / min, drawing speed: 800m / min.

[0025] 3. Alkali reduction treat...

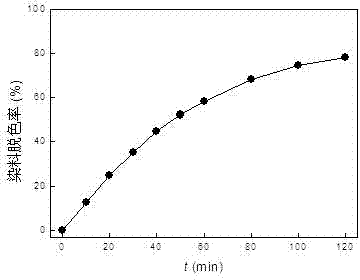

Embodiment 2

[0030] 1. Contains Nano TiO 2 Preparation of PET Masterbatch

[0031] The process is the same as the 1-step process in Example 1.

[0032] 2. Nano-TiO 2 -Preparation of PET color yarn

[0033] 15% by weight containing nano-TiO 2 PET masterbatch, 5% color masterbatch and 80% conventional PET chips, all the other are the same as the 2-step process in embodiment 1.

[0034] 3. Alkali reduction treatment

[0035] Process is the same as the 3-step process in Example 1.

[0036] 4. Photocatalytic degradation performance evaluation method

[0037] The experimental method was the same as the 4-step experimental method in Example 1, and the decolorization rate of the dye reached 78.2% after 2 hours of light irradiation.

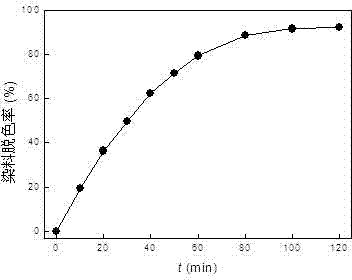

Embodiment 3

[0039] 1. Contains Nano TiO 2 Preparation of PET Masterbatch

[0040] The process is the same as the 1-step process in Example 1.

[0041] 2. Nano-TiO 2 -Preparation of PET color yarn

[0042] 25% by weight containing nano-TiO 2 PET masterbatch, 5% color masterbatch and 70% conventional PET chips, all the other are the same as the 2-step process in embodiment 1.

[0043] 3. Alkali reduction treatment

[0044] Process is the same as the 3-step process in Example 1.

[0045] 4. Photocatalytic degradation performance evaluation method

[0046] The experimental method was the same as the 4-step experimental method in Example 1, and the decolorization rate of the dye reached 92.3% after 2 hours of light irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com