Novel graphene-like molybdenum disulfide-based self-cleaning ecological glass and preparation method thereof

A molybdenum disulfide and graphene technology, applied in the direction of coating, can solve the problems of reducing photocatalytic performance and self-cleaning stability, and achieve the effect of improving the ability of photocatalytic degradation of organic substances, high purity and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

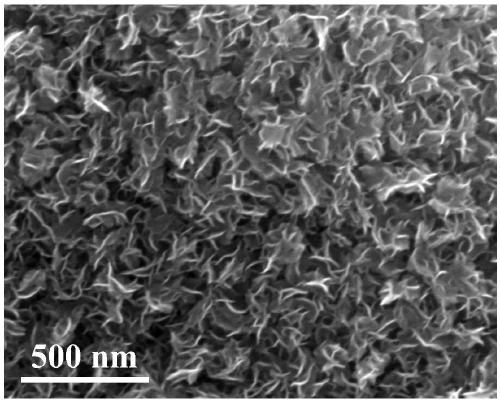

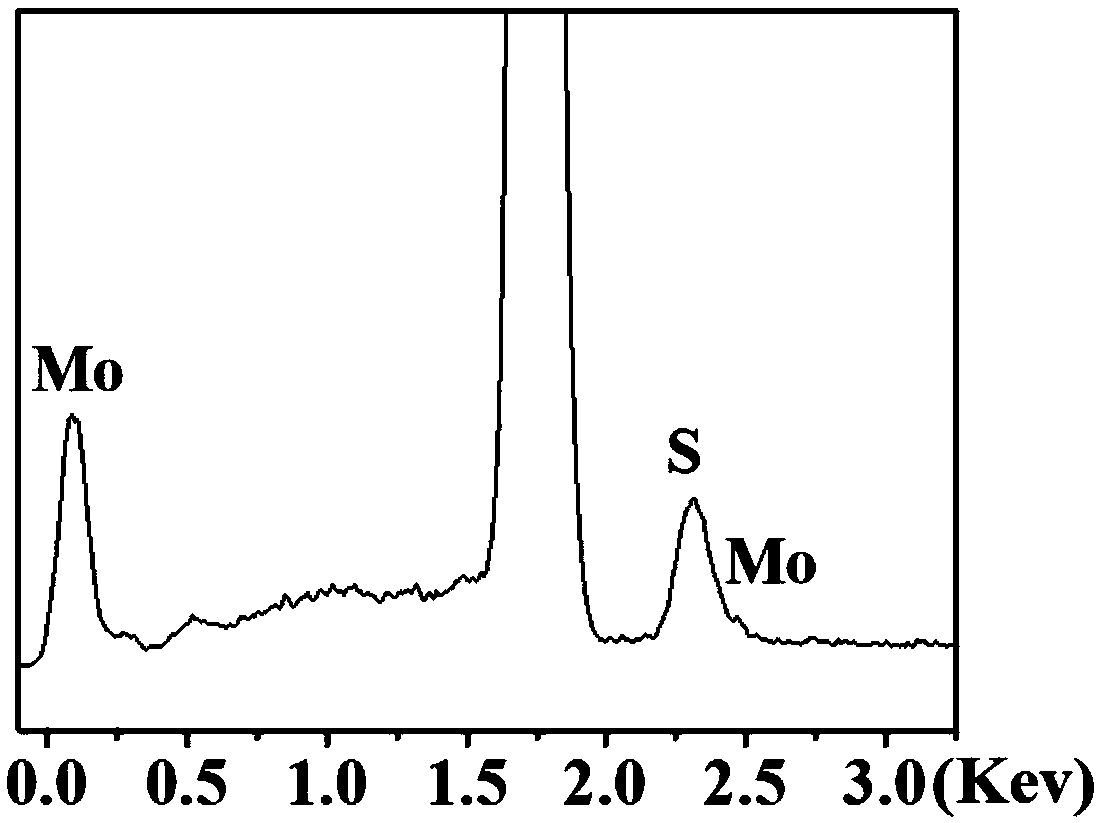

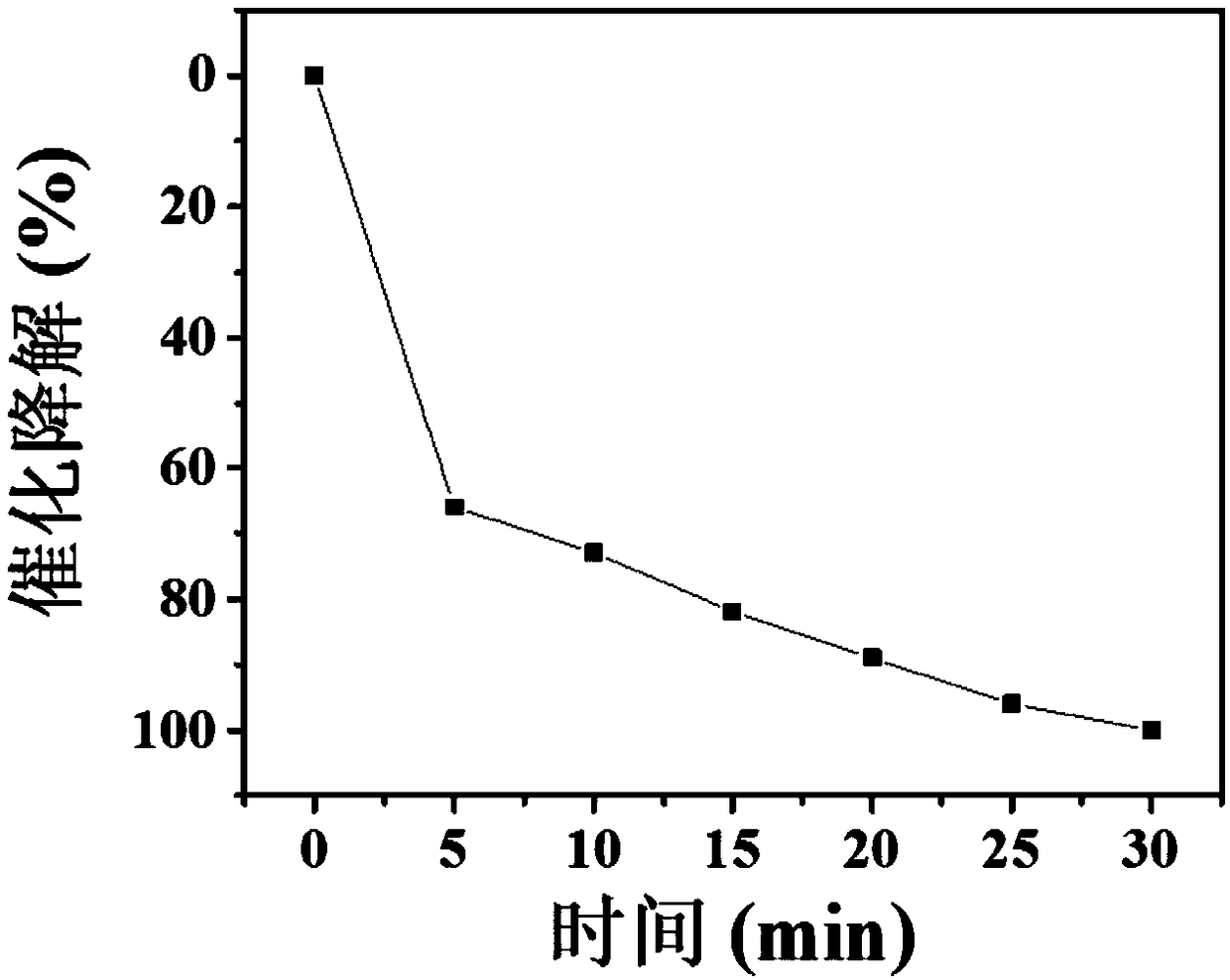

[0027] Remove ordinary stains on the glass surface with an area of 3cm×3cm with water and detergent, then soak the glass in acetone and ethanol and clean it ultrasonically for 30 minutes, and finally wash it repeatedly with deionized water for 3 times. Clean glass using N 2 Purging to remove surface moisture, the purging time is 3min. Take the clean glass and clean it with ultraviolet light for 15 minutes. The evaporation experiment of molybdenum trioxide precursor film was carried out on glass, and molybdenum trioxide powder (MoO 3 ) has a mass of 0.5 g and is placed in an evaporation heating crucible. The clean glass after UV cleaning is placed on top of the crucible. After the evaporation chamber is evacuated, the MoO is heated 3 The powder is evaporated, and the heating temperature is 400°C. Finally, a molybdenum trioxide film is deposited on the glass surface with a thickness of 100nm. Finally, perform molybdenum trioxide sulfide growth molybdenum disulfide self-c...

Embodiment 2

[0030] Remove ordinary stains on the glass surface with an area of 3cm×3cm with water and detergent, then soak the glass in acetone and ethanol and clean it ultrasonically for 30 minutes, and finally wash it repeatedly with deionized water for 3 times. Clean glass using N 2 Purging to remove surface moisture, the purging time is 3min. Take the clean glass and clean it with ultraviolet light for 15 minutes. The evaporation experiment of molybdenum trioxide precursor film was carried out on glass, and molybdenum trioxide powder (MoO 3 ) has a mass of 0.3 g and is placed in an evaporation heating crucible. The clean glass after UV cleaning is placed on top of the crucible. After the evaporation chamber is evacuated, the MoO is heated 3The powder is evaporated, and the heating temperature is 400°C. Finally, a molybdenum trioxide film is deposited on the glass surface with a thickness of 50nm. Finally, perform molybdenum trioxide sulfide growth molybdenum disulfide self-cle...

Embodiment 3

[0033] Remove ordinary stains on the glass surface with an area of 3cm×3cm with water and detergent, then soak the glass in acetone and ethanol and clean it ultrasonically for 30 minutes, and finally wash it repeatedly with deionized water for 3 times. Clean glass using N 2 Purging to remove surface moisture, the purging time is 3min. Take the clean glass and clean it with ultraviolet light for 15 minutes. The evaporation experiment of molybdenum trioxide precursor film was carried out on glass, and molybdenum trioxide powder (MoO 3 ) has a mass of 0.3 g and is placed in an evaporation heating crucible. The clean glass after UV cleaning is placed on top of the crucible. After the evaporation chamber is evacuated, the MoO is heated 3 The powder is evaporated, and the heating temperature is 400°C. Finally, a molybdenum trioxide film is deposited on the glass surface with a thickness of 30nm. Finally, perform molybdenum trioxide sulfide growth molybdenum disulfide self-cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com