Preparation method of hyperbranched polyester modified silver ion-loaded diatomite

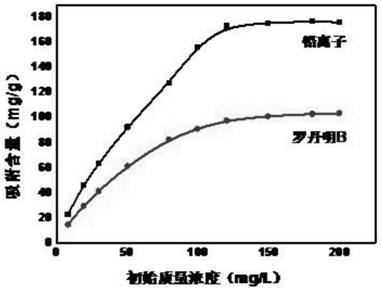

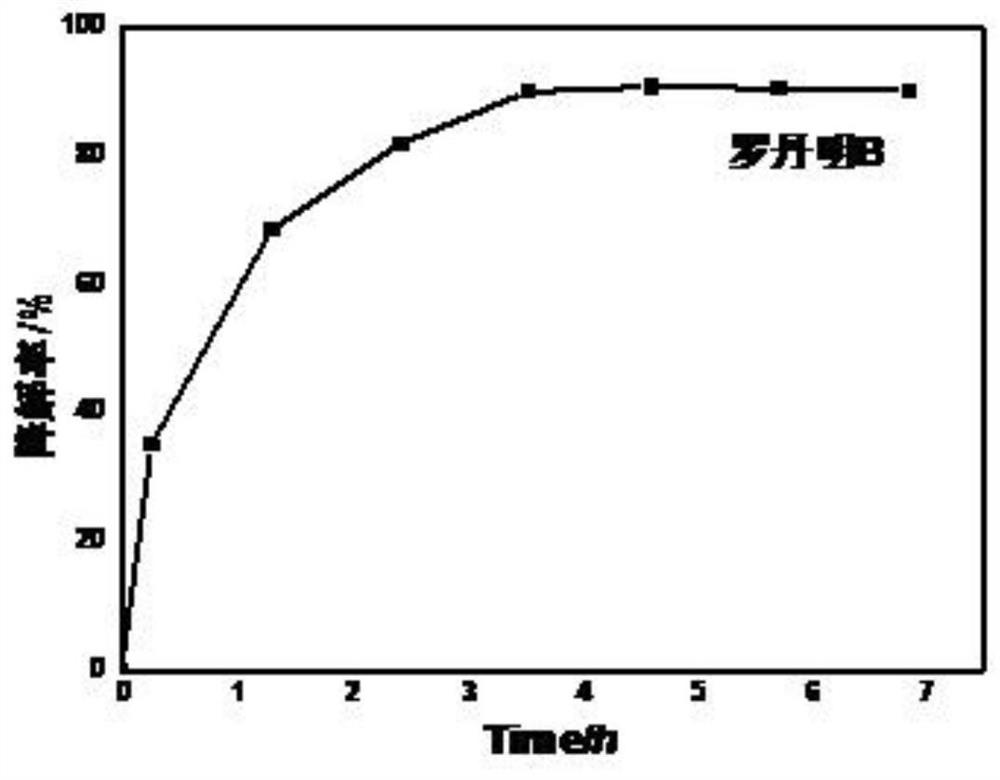

A technology of hyperbranched polyester and diatomite, applied in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve problems such as dye organic pollutant pollution, achieve high adsorption efficiency, low production cost, The effect of good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

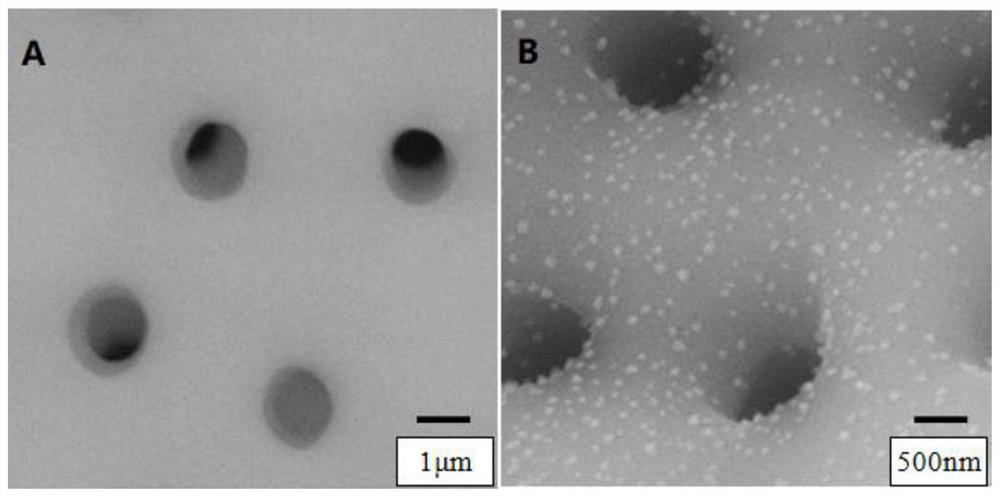

[0028] The preparation of hyperbranched polyester modified loaded silver ion diatomite (CA-Ag@DE) comprises the following steps:

[0029] (1) Preparation of silver ion loaded diatomite (Ag@DE)

[0030] Take 15g of dried diatomite, add 0.20mol / L ascorbic acid solution until the diatomite is completely wetted, dry at 105°C to constant weight, then crush the product and add 0.02% silver nitrate solution until the diatomite is completely wetted. Wet, let stand for 24 hours, and dry at 105°C to obtain silver ion-loaded diatomaceous earth (Ag@DE).

[0031] (2) Preparation of aminosilane-modified diatomite loaded with silver ions (A-Ag@DE)

[0032] Accurately weigh 10 g of diatomite powder loaded with silver ions, put it into 250 mL of NaOH solution with a concentration of 0.5 mol / L, stir at room temperature for 1 h, filter with suction, wash, and dry for later use.

[0033] Accurately weigh 1.5g of activated diatomite powder, put it into a beaker containing 30mL of ethanol solutio...

Embodiment 2

[0037] The preparation of loaded silver ion diatomite (Ag@DE) is the following steps:

[0038] Take 5g of dried diatomite, add 0.25mol / L ascorbic acid solution until the diatomite is completely wetted, dry at 105°C to constant weight, then pulverize the product and add 0.025% silver nitrate solution until the diatomite is completely wetted. Wet it completely, let it rest for 30 hours, and then dry it at 105°C to obtain silver ion-loaded diatomite (Ag@DE);

Embodiment 3

[0040] The preparation of hyperbranched polyester modified loaded silver ion diatomite (CA-Ag@DE) comprises the following steps:

[0041] (1) Preparation of silver ion loaded diatomite (Ag@DE)

[0042] Take 10g of dried diatomite, add 0.20mol / L ascorbic acid solution until the diatomite is completely wetted, dry at 105°C to constant weight, then crush the product and add 0.02% silver nitrate solution until the diatomaceous The soil is completely wetted, and after 24 hours of rest, it is dried at 105°C to obtain silver ion-loaded diatomaceous earth (Ag@DE).

[0043] (2) Preparation of aminosilane-modified diatomite loaded with silver ions (A-Ag@DE)

[0044] Accurately weigh 10 g of silver ion-loaded diatomite powder, put it into 250 mL of NaOH solution with a concentration of 0.5 mol / L, stir at room temperature for 1 h, filter with suction, wash, and dry for later use.

[0045]Accurately weigh 3g of activated diatomite powder, put it into a beaker containing 60mL of ethanol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com