Elliptical-surface aluminum plate unit module mounting structure, aluminum plate wall and mounting method thereof

A unit module and installation structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problem of difficult installation and construction of ultra-high super-large surface ellipsoid alloy wall aluminum panels, tensile and flexural strength of unit plates, and cross-section resistance. Insufficient shear strength, difficult to control the overall surface curvature and flatness, etc., to reduce quality risks, save labor installation costs, and improve decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

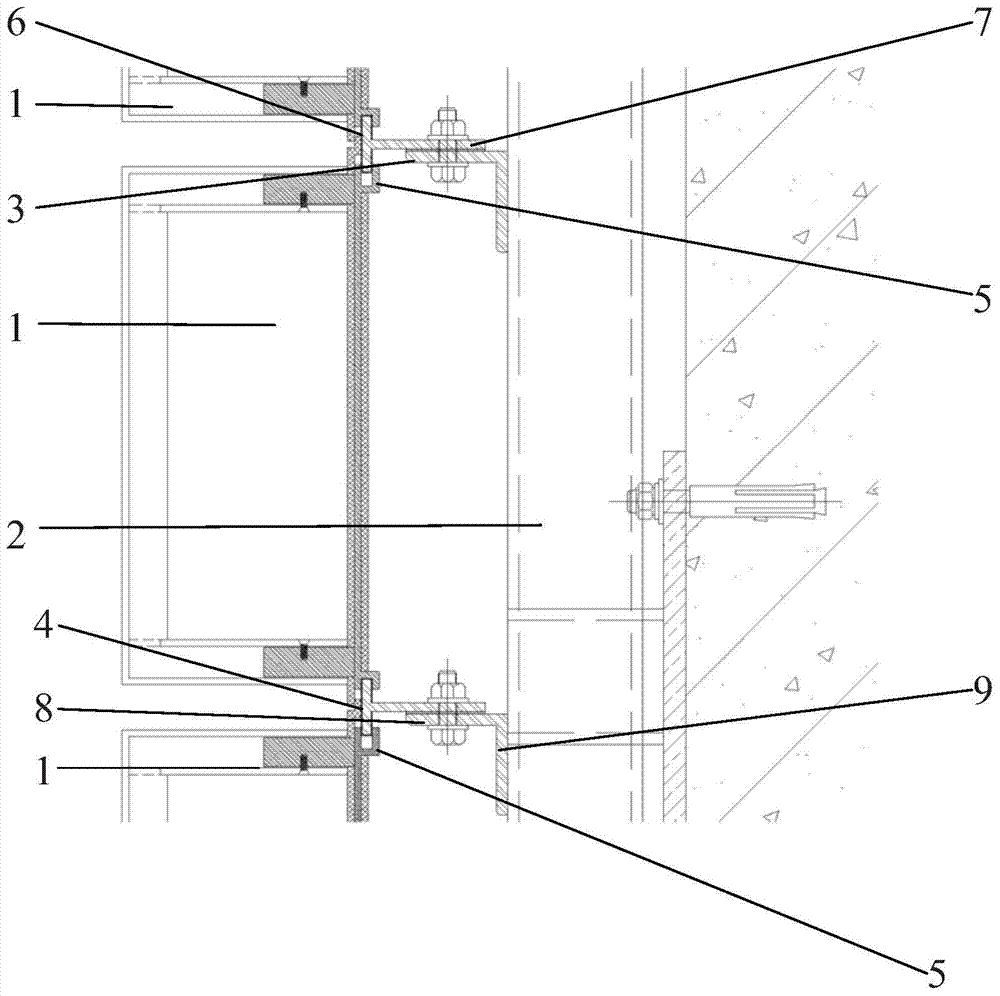

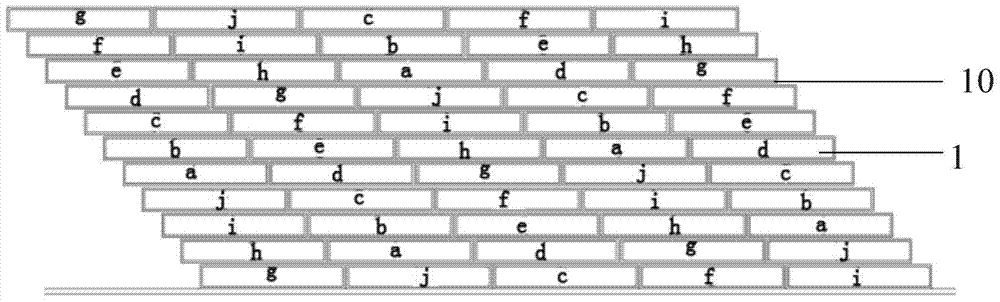

[0033] In order to achieve the purpose of the present invention, in some embodiments, such as figure 1 As shown, the installation structure of the elliptical aluminum plate unit module of the present invention includes a wall steel frame base layer 2, and also includes an aluminum plate unit module 1, and both ends of the aluminum plate unit module 1 are provided with tie points 3 and connectors 4, One end of the connecting piece 4 is clamped on the aluminum plate unit module 1 , and the other end of the connecting piece 4 is connected to the tie point 3 , and the tie point 3 is connected to the base layer 2 of the wall steel frame. The installation structure of the elliptical aluminum plate unit module of the present invention installs the aluminum plate unit module on the base layer of the wall steel frame through the tie points, and uses t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com