Grouting-free adhesive-bonded prestressed steel bar and preparation and construction method thereof

A technology of prestressed steel bars and construction methods, applied to structural elements, building components, building reinforcements, etc., can solve the problems of weakening the cooperating ability of prestressed bars and concrete, plugging pipes, and reducing the mechanical properties of prestressed bars, etc., to achieve Easy on-site use and quality control, good quality controllability, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

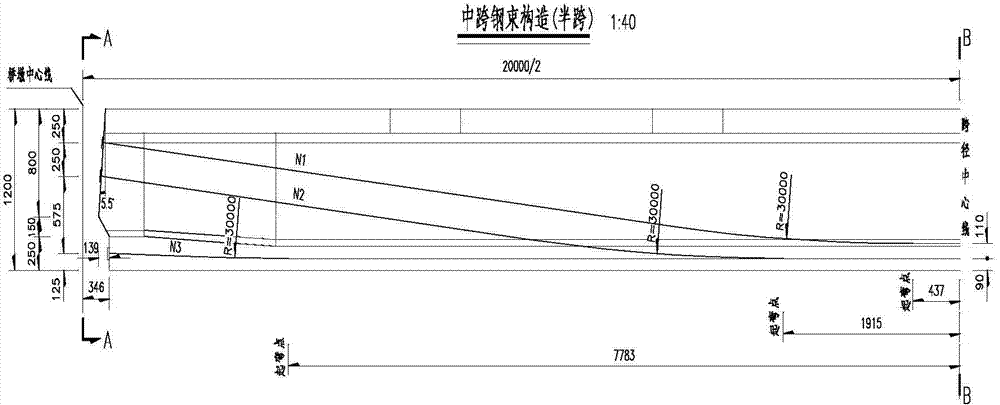

[0018] A 3×20m prestressed concrete simply supported small box girder bridge on a highway. The original design of the small box girder used 6 bundles of φ15.2 steel strands. 2 pieces of φ50 and 4 pieces of φ55 bellows, the wall thickness of the bellows is 1mm. After the concrete pouring is completed and the prestressed steel bars are stretched, a certain proportion of cement slurry is injected into the bellows through special grouting equipment. Fill the gap of the corrugated pipe, and make the steel strand pass through the cement slurry and the concrete beam as a whole. Design see image 3 .

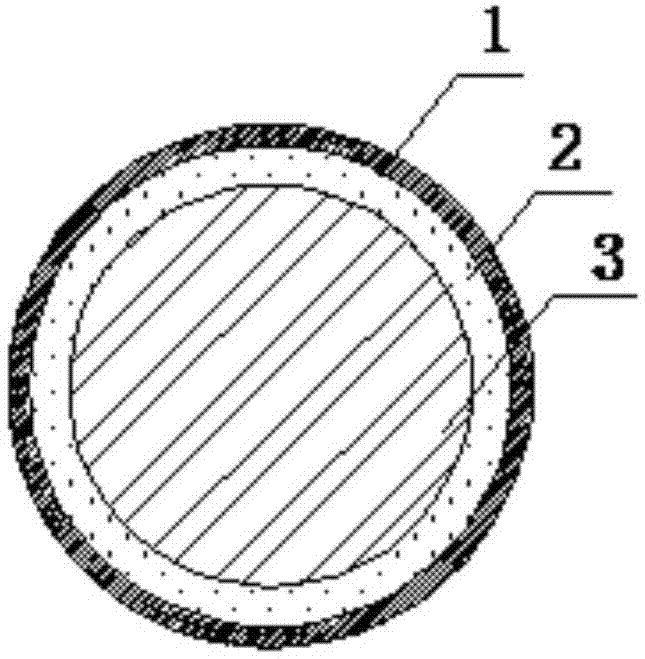

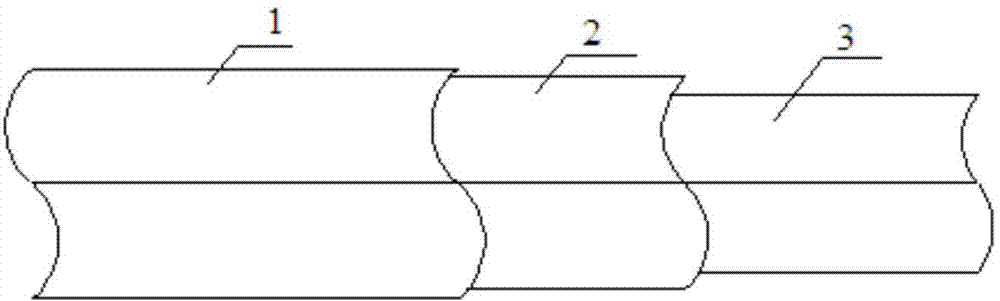

[0019] The preparation method of the glue-bonded prestressed steel bar without grouting according to the present invention, the preparation method is specifically: after filling the corrugated pipe with Huitian brand 6011 (HT606W) single-component heating and curing structure bonding epoxy glue , insert the prestressed steel bar into the bellows, so that the prestressed steel bar can ...

Embodiment 2

[0022] A 90+150+90m prestressed concrete low-tower cable-stayed bridge on a certain grade of road. The original design of the vertical prestressing of the concrete main girder uses φ32 fine-rolled rebar. Before pouring concrete, it needs to be pre-embedded φ50 plastic corrugated pipe, the wall thickness of the corrugated pipe is 1mm. After the concrete pouring is completed and the prestressed steel bars are stretched, a certain proportion of cement slurry is injected into the corrugated pipe through special grouting equipment to fill the gap of the corrugated pipe. , and make the steel strand pass through the cement slurry and the concrete beam as a whole.

[0023] The preparation method of the grouting-free glue-bonded prestressed steel bar according to the present invention, the preparation method is specifically: filling the Huitian brand 6011 (HT606W) single-component heat-cured structural adhesive ring in the φ36 steel bellows After the oxygen glue, insert the prestressed...

Embodiment 3

[0026] A 90+150+90m prestressed concrete low-tower cable-stayed bridge on a certain grade of road. The original design of the vertical prestressing of the concrete main girder uses φ32 fine-rolled rebar. Before pouring concrete, it needs to be pre-embedded φ50 steel bellows, the wall thickness of the bellows is 1mm. After the concrete pouring is completed and the prestressed steel bars are stretched, a certain proportion of cement slurry is injected into the bellows through special grouting equipment to fill the bellows. gaps, and make the steel strand pass through the cement slurry and the concrete beam as a whole.

[0027]The preparation method of the grouting-free glue-bonded prestressed steel bar according to the present invention, the preparation method is specifically: filling the Huitian brand 6011 (HT606W) single-component heat-cured structural adhesive ring in the φ36 steel bellows After the oxygen glue, the glue also added 1% of the total mass of Russula ketoterpene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com