Strip-shaped LED filament support continuous punching mould

A technology of LED filaments and stamping dies, applied in the field of stamping dies, can solve the problems of increasing investment in equipment and personnel, affecting the profitability of enterprises, and unstable product quality, etc., achieving the effect of reducing equipment and personnel, meeting production requirements, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

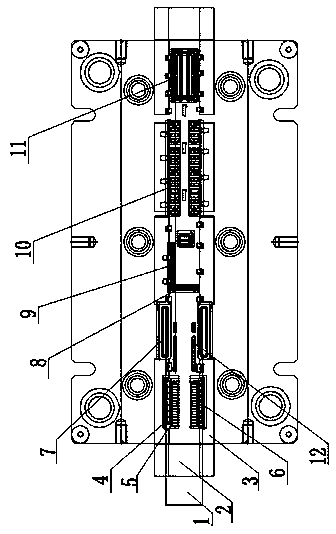

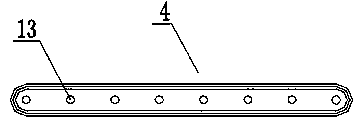

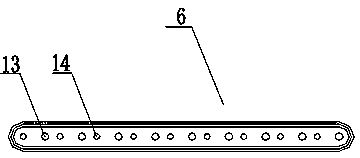

[0028] Such as Figure 1~8 As shown, a continuous stamping die for a strip-shaped LED filament support, including a rough cutting and punching module, a trimming and pressing line module, a punching round small hole module, a forming module and a cutting die set in sequence from left to right Die group, rough cutting punching module comprises punch A 4, punch B 6 and two matching cutters 5, punch A 4, punch B 6 and cutter 5 are positioned on the upper splint 3; trimming The pressing module includes two matching pressing blocks 12 and two matching convex cutting dies 7, the pressing blocks 12 are located on the upper template 1, and the convex cutting dies 7 are located on the upper splint 3; It includes a small hole punch 9 and a side punch 8. The small hole punch 9 is set on the upper backing plate 2, and the side punch 8 is set on the upper template 1; 10 is provided with several punches 16 and two mirrored punching blocks 17; the cutting die group is composed of two sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com