Nitrogen protective continuous type brazing furnace

A technology of nitrogen protection and brazing furnace, applied in welding equipment, electric heating devices, auxiliary devices, etc., can solve problems such as long welding time, prone to water leakage, complex structure, etc., to improve brazing efficiency and quality, and improve heating efficiency , The effect of simplifying the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

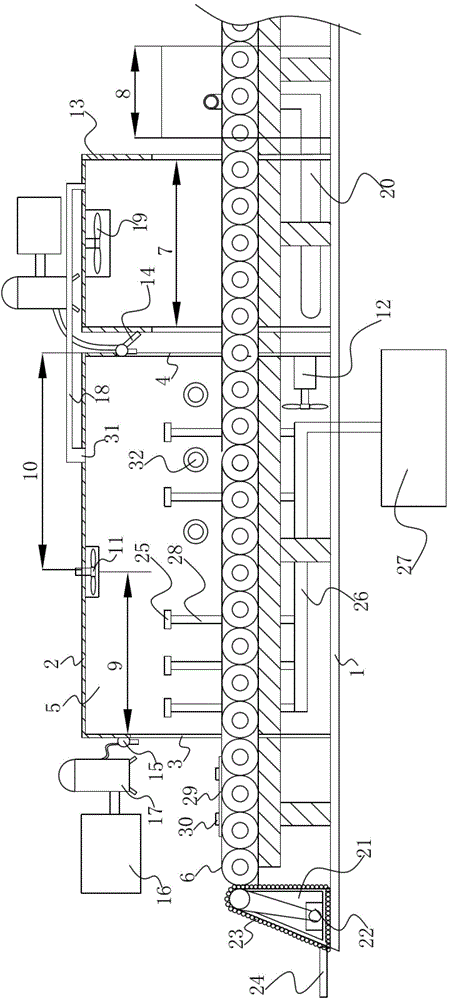

[0018] refer to figure 1 , the present invention comprises a frame 1, a furnace body 2 fixed on the frame 1 and provided with a furnace 5 therein, the furnace body 2 is provided with an inlet 3 and an outlet 4 for entering and leaving the furnace, the inlet 3 and the outlet 4 places are provided with a nitrogen sealing mechanism, a nitrogen protection system is provided in the furnace 5, a conveyor belt 6 that runs through the inlet 3 and the outlet 4 of the furnace body 2 is provided on the frame 1, and the conveyor belt 6 is provided with It can be transported to the fixture in the furnace 5 by the conveyor belt 6. The fixture is made of austenitic stainless steel for fixing the brazing object. The upper feeding mechanism, the other end is provided with an air-cooled zone 7 and a water-cooled zone 8 located on the conveyor belt 6 in turn, the furnace 5 is provided with a preheating zone 9 and a heating zone 10, and the preheating zone 9 is set on the Between the inlet 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com