Preparation method of spherical strontium carbonate

A strontium carbonate and spherical technology is applied in the field of preparation of spherical strontium carbonate, which can solve the problems of high cost, inability to achieve large-scale production, and high equipment cost, and achieve the effects of low cost, wide source of production raw materials, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

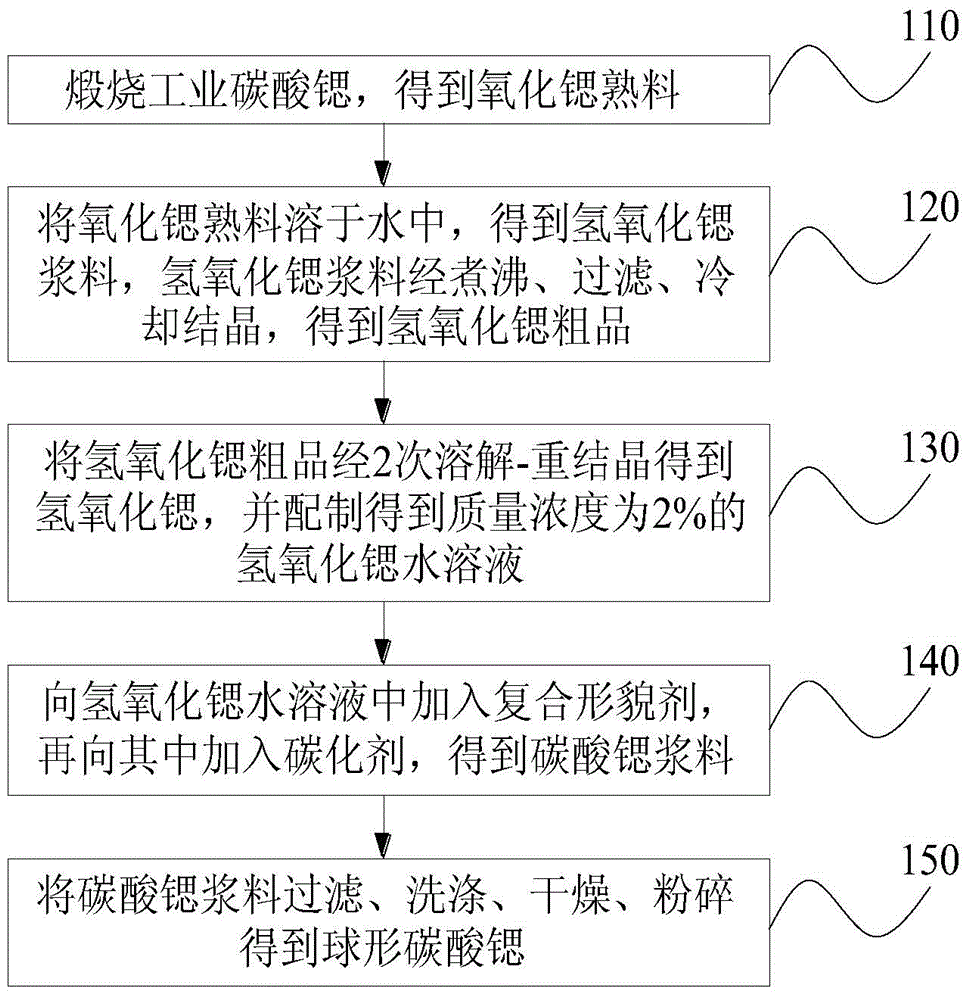

[0028] refer to figure 1 , the preparation method according to the spherical strontium carbonate of embodiment 1 of the present invention comprises the steps:

[0029] In step 110, industrial strontium carbonate is calcined to obtain strontium oxide clinker.

[0030] Specifically, 25g of industrial strontium carbonate (the content of strontium carbonate is about 95%) was weighed, placed in a high-temperature calciner and calcined at 1250° C. for 0.5 h to obtain strontium oxide clinker.

[0031] In step 120, the strontium oxide clinker is dissolved in water to obtain strontium hydroxide slurry, and the strontium hydroxide slurry is boiled, filtered, cooled and crystallized to obtain crude strontium hydroxide.

[0032] Specifically, slowly add the strontium oxide clinker obtained in step 110 into water according to the solid-to-liquid mass ratio of 1:10, and stir while adding, and obtain strontium hydroxide slurry after the leaching reaction continues for 30 minutes; The stron...

Embodiment 2

[0043] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 2 and embodiment 1 is that in step 110, the calcination temperature of industrial strontium carbonate is 1250°C, and the calcination time is 1h to obtain strontium oxide clinker; in step 120, the solid-liquid mass ratio Add water to the strontium oxide clinker under the condition of 1:12, boil it after leaching for 30 minutes, obtain the crude product of strontium hydroxide through hot filtration, cooling and crystallization; in step 130, the crude product of strontium hydroxide is dissolved three times Crystallization obtains strontium hydroxide, and by strontium hydroxide preparation mass concentration is the strontium hydroxide aqueous solution of 4%; In step 140, in the strontium hydroxide aqueous solution, add 27.84g edetate disodium and 19.94g hexahydrate chlorine Strontium...

Embodiment 3

[0046] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 3 and embodiment 1 is that in step 110, the calcination temperature of industrial strontium carbonate is 1200°C, and the calcination time is 1.5h to obtain strontium oxide clinker; Add water to the strontium oxide clinker at a ratio of 1:15, boil it after leaching for 30 minutes, heat filter, cool and crystallize to obtain the crude product of strontium hydroxide; in step 130, the crude product of strontium hydroxide is dissolved three times- Recrystallization obtains strontium hydroxide, and by strontium hydroxide preparation mass concentration is the strontium hydroxide aqueous solution of 6%; In step 140, in the strontium hydroxide aqueous solution, add 55.40g edetate disodium and 39.68g chloride Strontium is used as a composite morphology agent, so that the amount of strontiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com