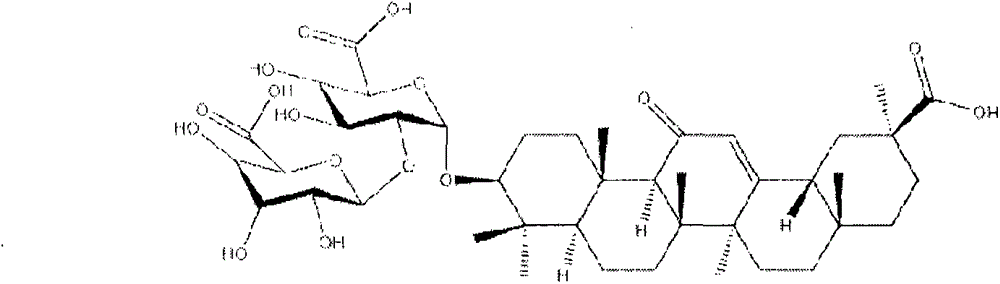

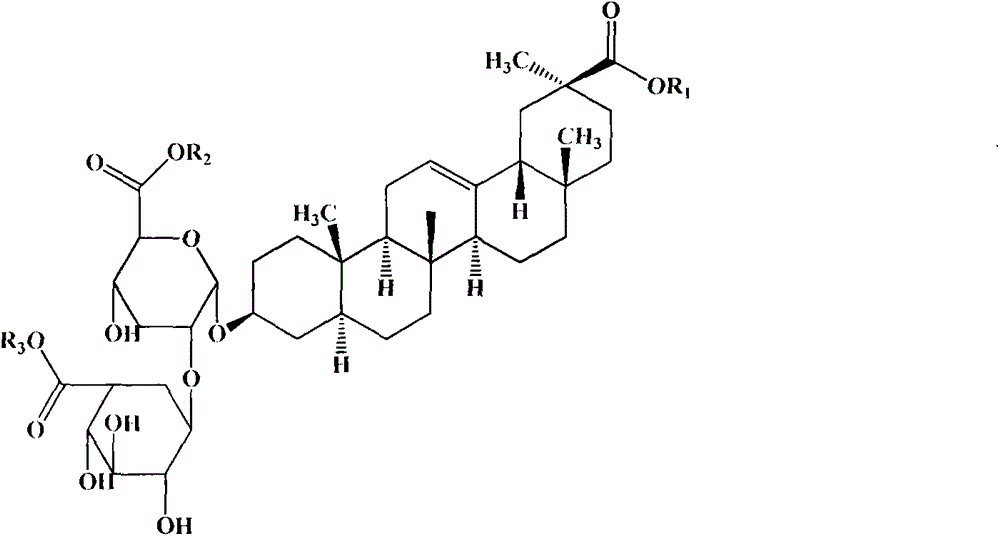

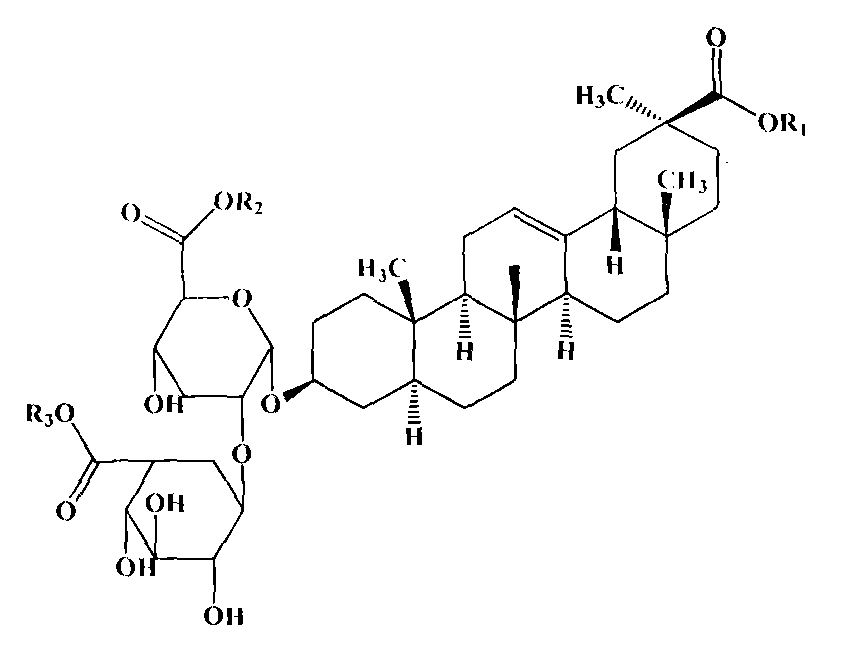

Preparation method of ammonium 18alpha,beta-H-glycyrrhetate and hydrate thereof

A technology of triammonium glycyrrhizate and monoammonium glycyrrhizate, applied in the field of 18α, can solve the problems of incomplete separation, residual products, affecting yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Refining of glycyrrhizic acid: Add 500g of crude glycyrrhizic acid with a content of 75% to 250mL of ethanol with a volume fraction of 95%, stir and extract at 50-60°C for 2.0h, filter the residue with 200mL of ethanol with a volume fraction of 95% at 50-60°C Stir and extract for 1.5 h, and filter the filter residue with 150 mL of ethanol with a volume fraction of 95% at 50-60° C. for 1.0 h. Combine the extracts, add 0.5% EDTA, add 3-5% (W / W) powdered activated carbon, keep warm at 50-60°C for 30 minutes, filter, concentrate the filtrate under reduced pressure to a relative density of 1.15-1.20, let stand, and crystallize. The crystals were peeled off, moved to a porcelain plate, put into a vacuum desiccator, and dried at a temperature of 40-50° C. to obtain 396 g of 18α, β-H-glycyrrhizic acid mixture, with a content of 98.8%.

[0045] Glycyrrhizic acid configuration transformation: Add 200g of the refined glycyrrhizic acid mixture and 800mL of N,N-dimethylformamide int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com