Method for modifying epoxy resin by reaction type multi-block copolymer

A multi-block copolymer and epoxy resin technology, which is applied in the field of modified epoxy resin, can solve the problems of harsh reaction conditions, inability to form obvious microphase structure, and inability to significantly improve the performance of modified epoxy resin to achieve toughness Improve and increase the effect of interface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

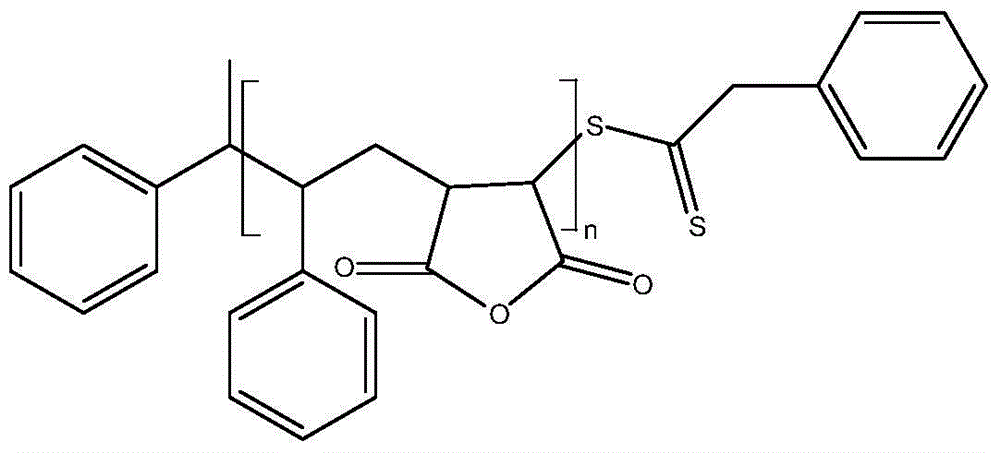

[0017] Add 0.08g of compatibilizer to 100g of E-44 epoxy resin, mix well, add 1.7g of styrene, heat up to 60°C, add 0.01g of azobisisobutyronitrile, start the polymerization reaction; add 3.4g after 6 hours n-butyl acrylate, after 3 hours of polymerization reaction, obtained the epoxy resin modified by reactive multi-block copolymer. The structural formula of the compatibilizer is:

[0018]

[0019] Wherein the number of units of styrene is 4, the number of units of maleic anhydride is 4, and the number average molecular weight is 1000.

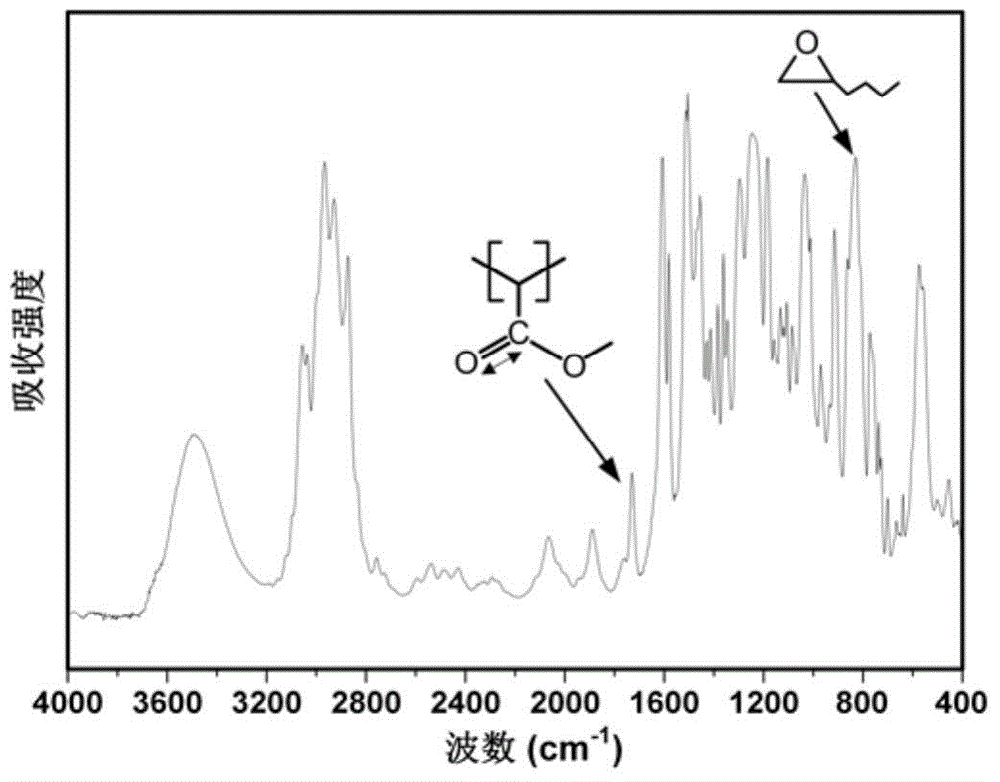

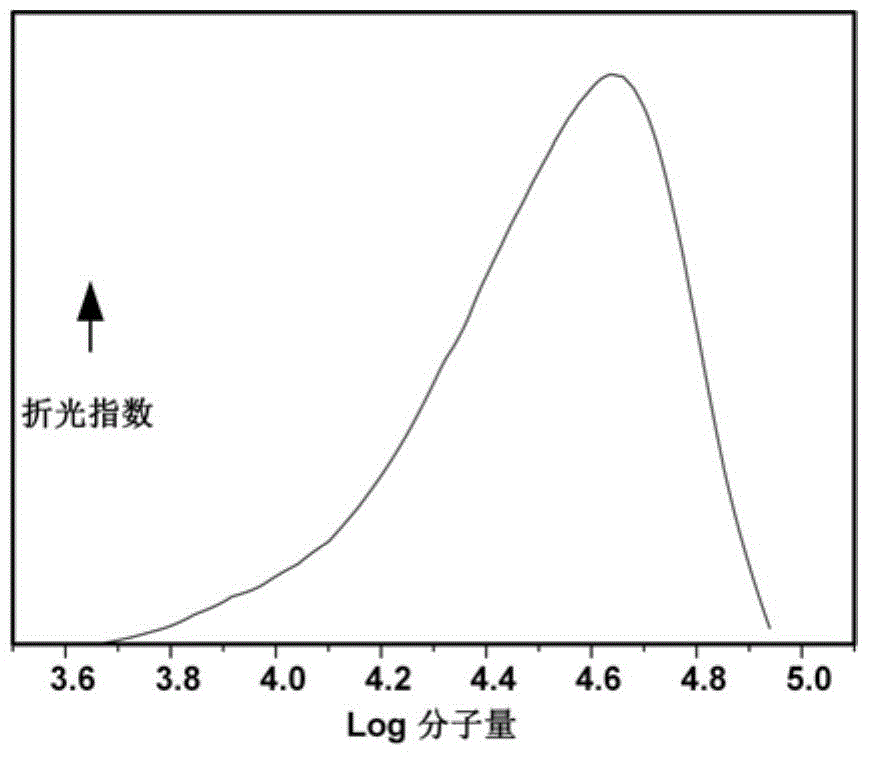

[0020] The infrared spectrum of the reaction product is attached figure 1 As shown, 1730cm -1 Nearby characteristic peaks represent the generation of ester bonds, indicating that a covalent bond has been formed between the compatibilizer and bisphenol A diglycidyl ether, and the product obtained by this method has reactivity. Further carried out GPC test to this mixture, the high molecular weight part of GPC curve is as attached figur...

Embodiment 2

[0022] Add 0.53g compatibilizer to 100g E-51 epoxy resin, mix well, add 2g methyl methacrylate, heat up to 60°C, add 0.11g dicumyl peroxide, start polymerization reaction; add after 6 hours 4.30g of n-butyl acrylate, after polymerization reaction for 3 hours, obtained the epoxy resin modified by reactive multi-block copolymer. The structural formula of the compatibilizer is:

[0023]

[0024] Wherein the number of units of styrene is 4, the number of units of maleic anhydride is 4, and the number average molecular weight is 1000.

Embodiment 3

[0026] Add 0.74g compatibilizer to 100g E-51 epoxy resin, mix well, add 8.42g methyl methacrylate, heat up to 60°C, add 0.02g benzoyl peroxide, start polymerization reaction; after 8 hours 16.84g of n-butyl acrylate was added, and after 5 hours of polymerization reaction, a reactive multi-block copolymer-modified epoxy resin was obtained. The structural formula of the compatibilizer is:

[0027]

[0028] Wherein the number of units of styrene is 50, the number of units of maleic anhydride is 50, and the number average molecular weight is 10000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com