Treatment method for moisture-proof surface of resin-based insulating material

A technology for insulating materials and processing methods, which is applied in the field of preparation of moisture-proof surfaces of resin-based insulating materials, can solve problems such as tunnel humidity, large dust, insulation damage, tunnel water vapor, and large dust, and achieve low cost, increased roughness, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

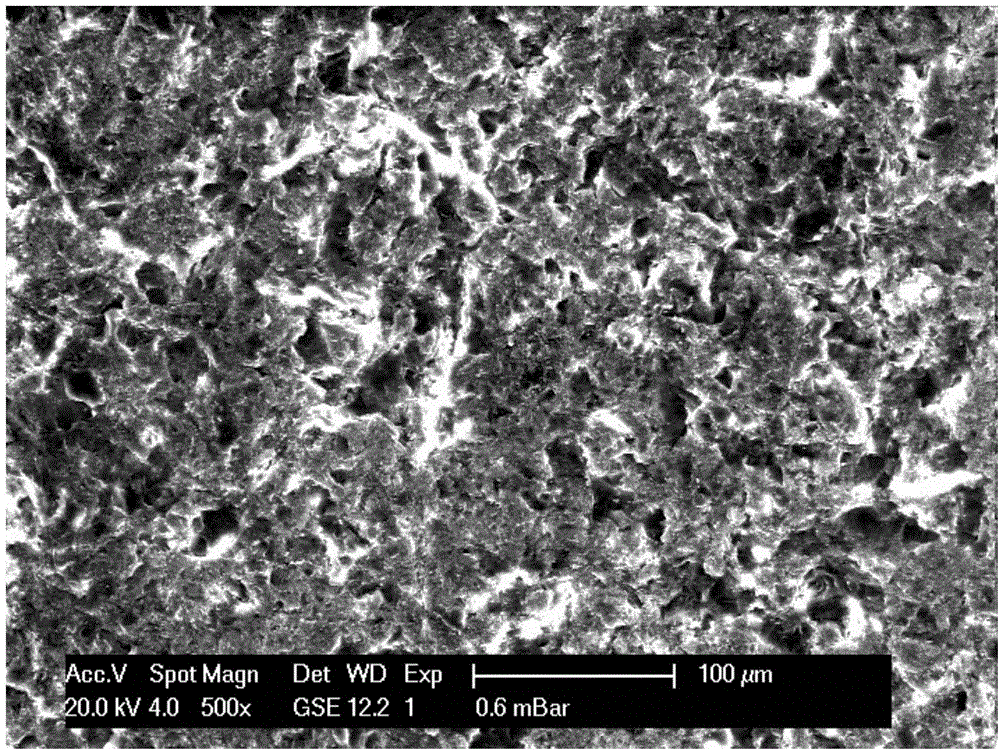

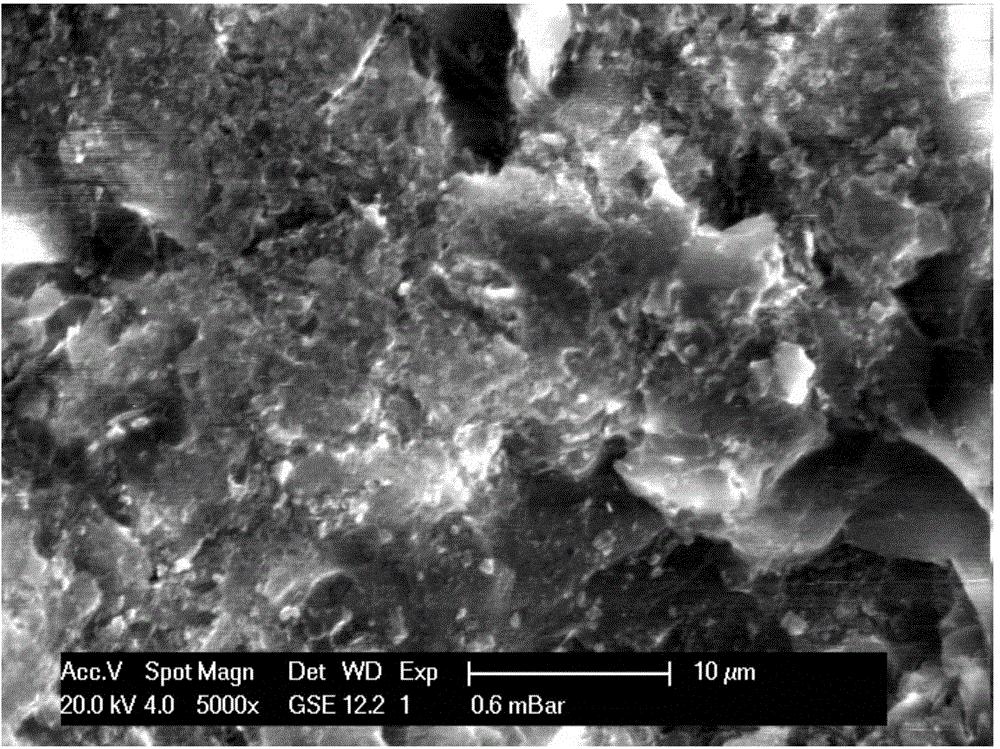

[0034] First, use 20-mesh brown corundum sand pellets to sandblast the surface of the resin-based insulating pad for subway screen doors under 0.6MPa air pressure until the surface of the workpiece is completely roughened. Then use 180-mesh glass sand pellets and 0.4MPa air pressure. Next, sand blast the entire surface of the insulating pad again to build a multi-level rough structure, such as figure 1 and 2 As shown; put the workpiece into 10g / L NaOH aqueous solution, treat it in a water bath at 50°C for 15 minutes, take it out, put it in clean water and ultrasonically clean it for 10 minutes, and then use oxygen plasma after drying for 20 minutes at a power of 18W; finally, Place the insulating mat in a vacuum drying oven, add 0.1 mL of fluorinated siloxane dropwise next to it, and place it in an airtight place for 1 hour to obtain an insulating mat with moisture-proof and anti-condensation functions.

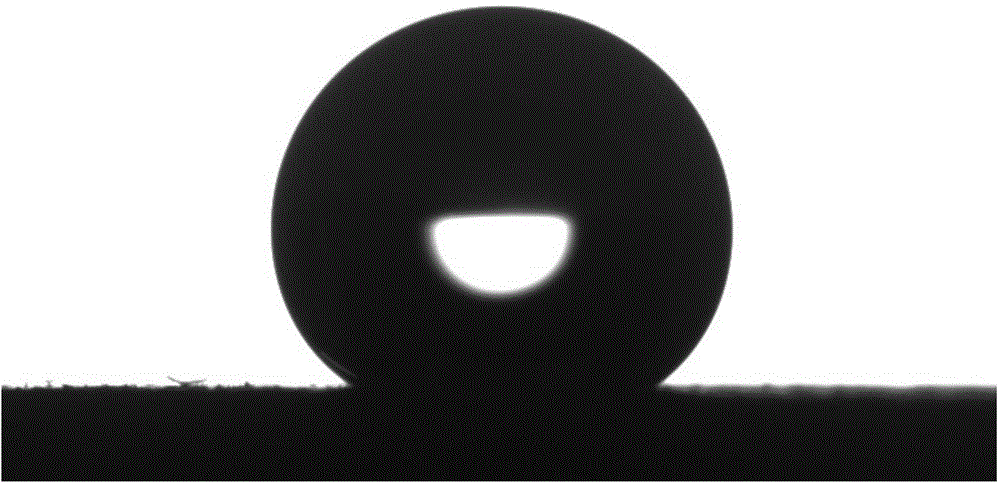

[0035] The contact angle measurement results show that the contact angl...

example 2

[0037]First, use 80-mesh white corundum and glass sand mixed shot (mixed by weight ratio 1:1), sandblast the insulating material under 0.5MPa air pressure until the surface of the workpiece is completely roughened, then use 200-mesh corundum shot, Under the condition of 0.5MPa air pressure, the entire surface of the insulating material is sandblasted again, and the sand shot can be one or more mixtures of brown corundum, white corundum, glass sand, corundum or stainless steel sand;

[0038] Put the workpiece into 20g / L H 2 SO 4 Aqueous solution, treated in a water bath at 80°C for 10 minutes, after taking it out, put it in clean water and ultrasonically clean it for 15 minutes, then use oxygen plasma after drying, and treat it with 18W power for 30 minutes; finally, put the insulating workpiece in a vacuum drying oven, next to it Add 0.2mL of fluorinated siloxane dropwise and place it airtight for 1.2h, then the resin-based insulating material will have a moisture-proof and a...

example 3

[0040] First, use 150-mesh corundum sand shot to sandblast the insulating material under 0.4MPa air pressure until the surface of the workpiece is completely roughened, then use 320-mesh glass sand shot to blast the insulating material again under 0.4MPa air pressure. Sand blasting treatment; put the workpiece into 30g / L NaOH aqueous solution, treat it in a water bath at 60°C for 20 minutes, take it out and put it in clean water for ultrasonic cleaning for 20 minutes, and then use oxygen plasma after drying for 40 minutes under the condition of 18W power; Place the insulating workpiece in a vacuum drying oven, add 1mL of fluorinated siloxane dropwise next to it, and place it in an airtight place for 2 hours, so that the resin-based insulating material has a moisture-proof and anti-condensation surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com