Crude oil emulsion fluid electrostatic coalescer

An electrostatic coalescence and emulsion technology, applied in the direction of electricity/magnetic dehydration/emulsion breaking, etc., can solve the problems of easy breakdown of electrodes, low coalescence efficiency, and inability to effectively use turbulent pulsation dielectrophoretic coalescence, etc. Achieve the effects of improving coalescence efficiency, enhancing processing capacity, and good coalescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

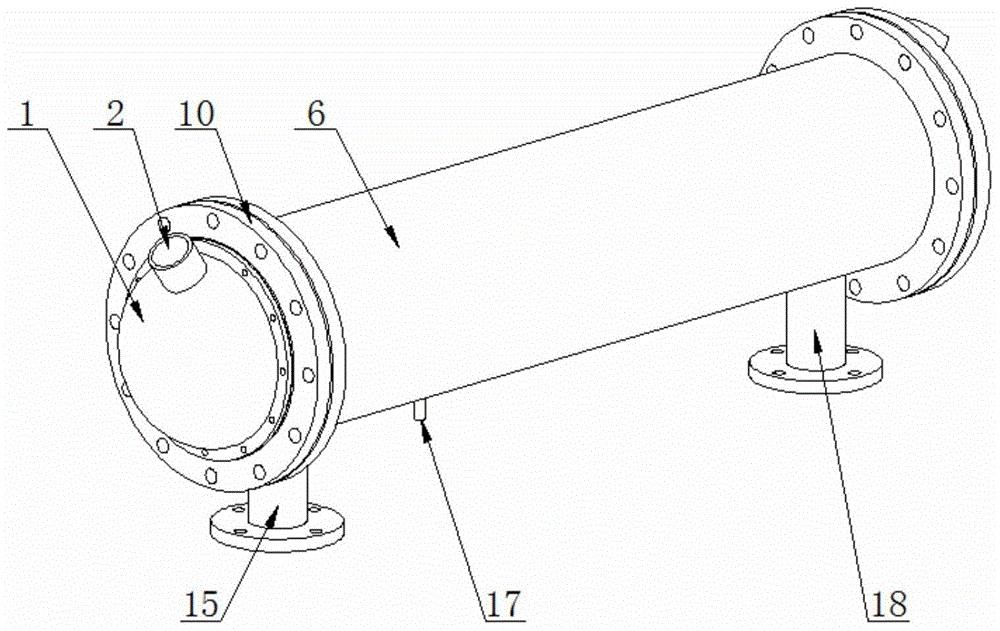

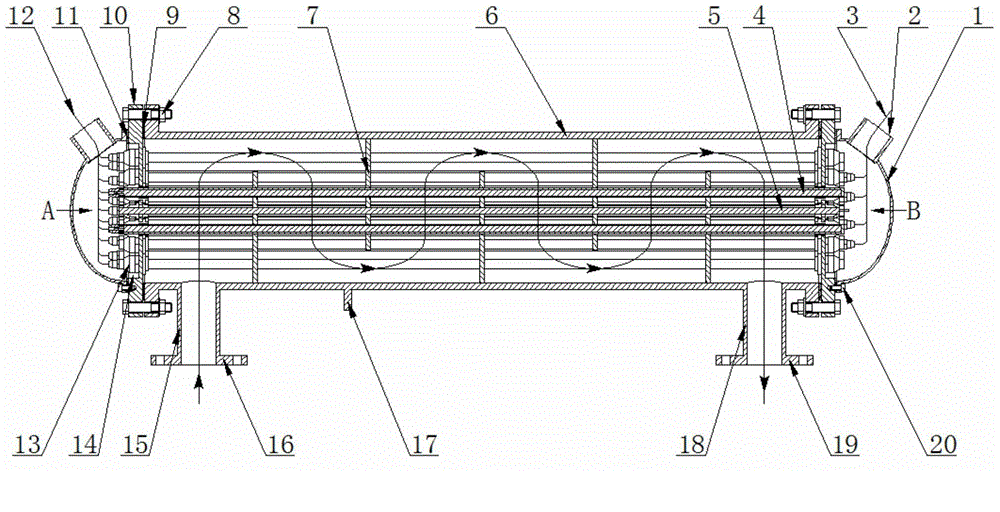

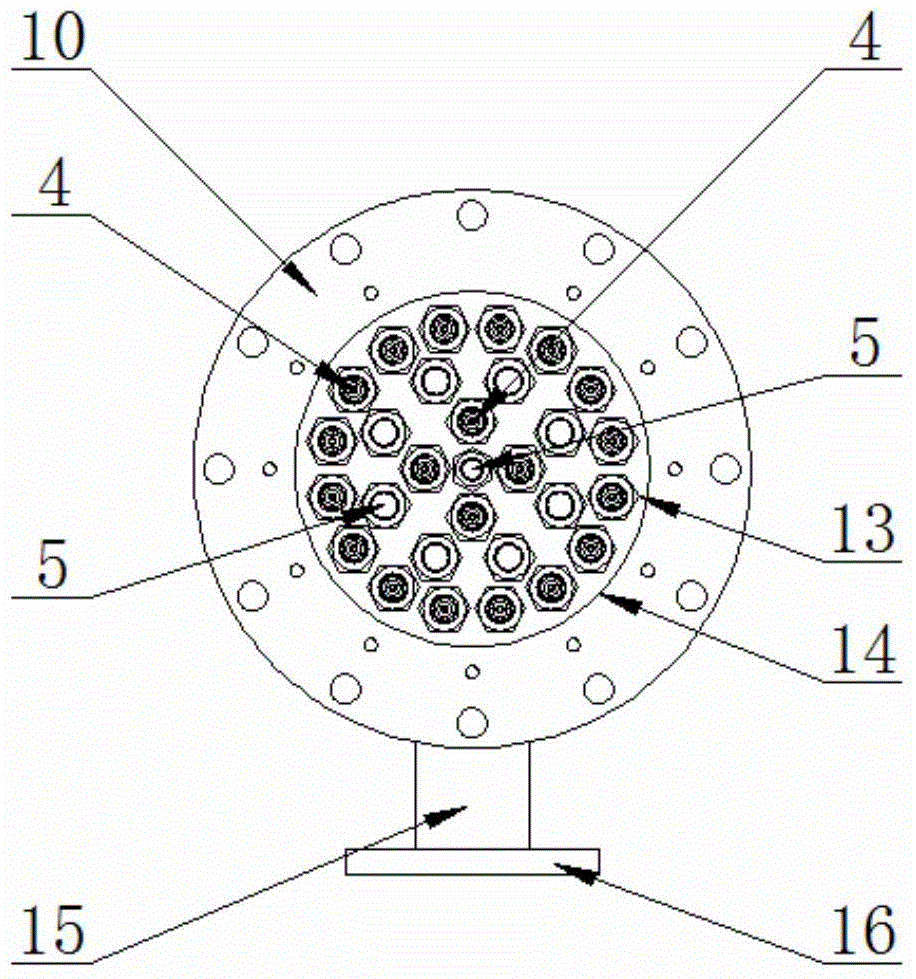

[0034] Reference attached figure 1 ~ attached Figure 7 , the present invention consists of a high / low voltage terminal cover 1, a high / low voltage cable lead hole 2, a low voltage cable 3, a high voltage columnar insulating electrode 4, a low voltage columnar insulating electrode 5, a coalescer cylinder 6, a baffle support plate 7, Insulation head fastening bolt 8, crude oil emulsion gasket 9, insulation head 10, transformer oil gasket 11, high voltage cable 12, electrode fixing sealing joint 13, stepped groove 14, inlet pipe 15, inlet connection Flange 16, barrel grounding terminal 17, outlet pipe 18, outlet connecting flange 19, fastening bolts 20 on the terminal face cover, high-voltage electrode guide hole 21, low-voltage electrode guide hole 22, electrode lead sealing joint 23, electrode insulation shell Tube 24, electrode terminal 25, fastening sealing thread 26, sealing rubber pad 27, electrode metal skeleton 28 and so on.

[0035] Reference attached figure 1 And at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com