Fuel gas processing method for FLNG (floating liquefied natural gas) oil-gas storage and offloading device

A technology of liquefied natural gas and liquefaction equipment, which is applied in the field of fuel gas treatment of floating liquefied natural gas oil and gas storage and unloading equipment, which can solve the problems of high energy consumption and achieve energy-saving and efficient operation, reduce waste, and reduce the liquefaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

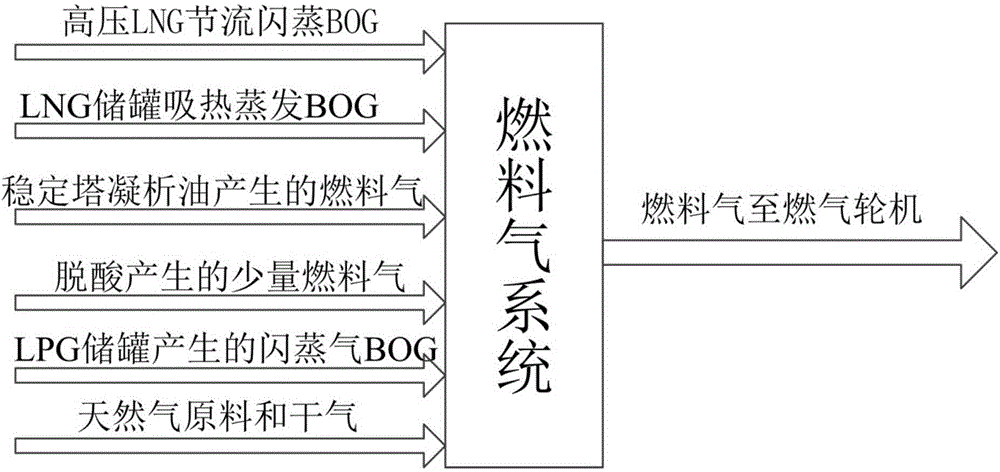

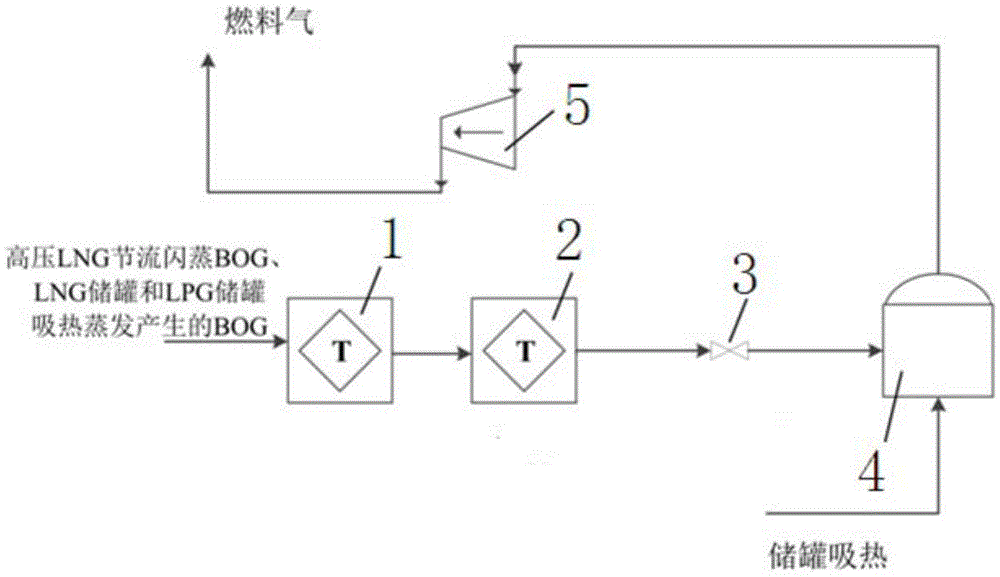

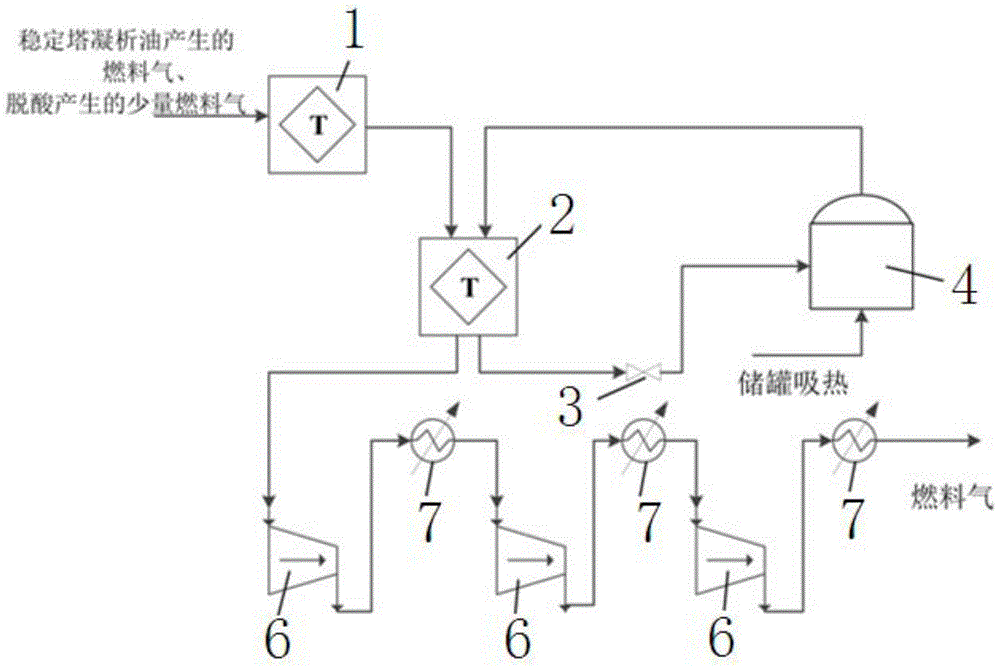

[0037] 1) Fuel gas sources include high-pressure LNG throttling flash BOG, BOG evaporated from LNG storage tanks, flash gas BOG from LPG storage tanks, fuel gas from condensate oil in the stabilization tower, and a small amount of fuel gas from deacidification , also includes the dry gas and natural gas produced by the light hydrocarbon recovery unit in the light hydrocarbon recovery process, including the specific parameters such as the temperature, pressure and flow rate of the fuel gas source, and the determinants of the various gas source parameters (as shown in Table 1).

[0038] Table 1 Characteristics of fuel gas source

[0039]

temperature °C

pressure bar

Flow t / h

Remark

High pressure LNG throttling flash BOG

-160

1.2

21.2

By optimizing the balance with the fuel gas system

LNG storage tank endothermic evaporation BOG

-160

1.2

6.2

Depends on the LNG storage tank; fixed value

Fuel gas from s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com