Cleansing Bar Compositions Comprising A High Level Of Water

A technology of composition and cleaning bar, which is applied in the direction of soap detergent composition, detergent composition, surface active non-soap compound and washing composition, etc., and can solve problems such as difficulty in maintaining high water content of finished bar soap composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

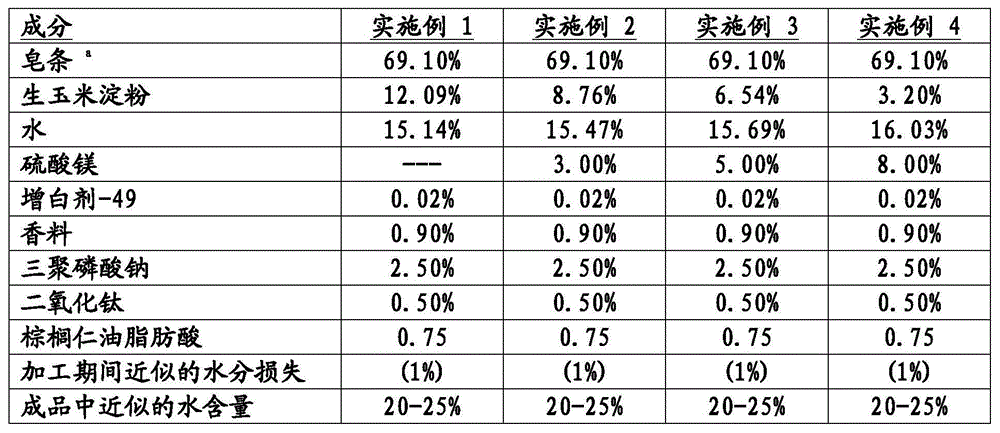

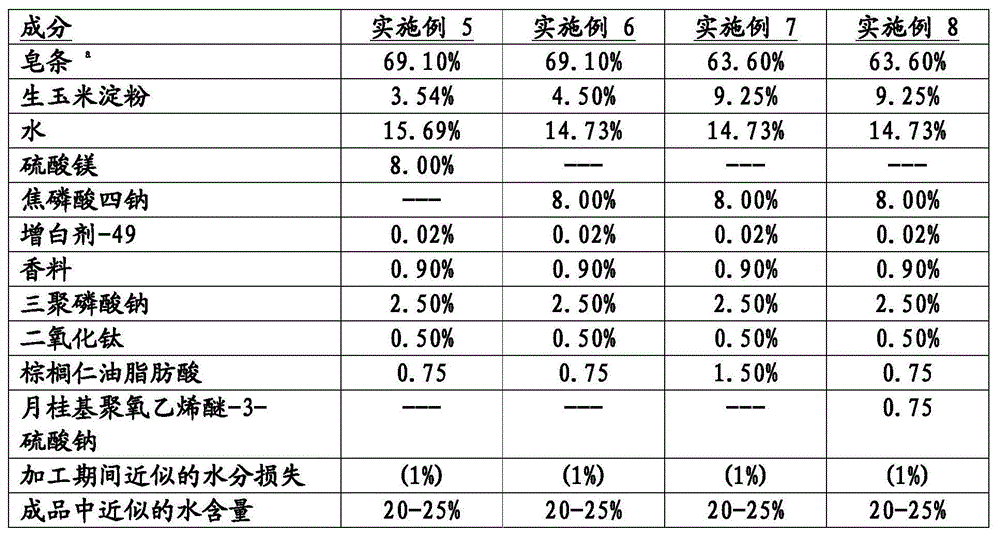

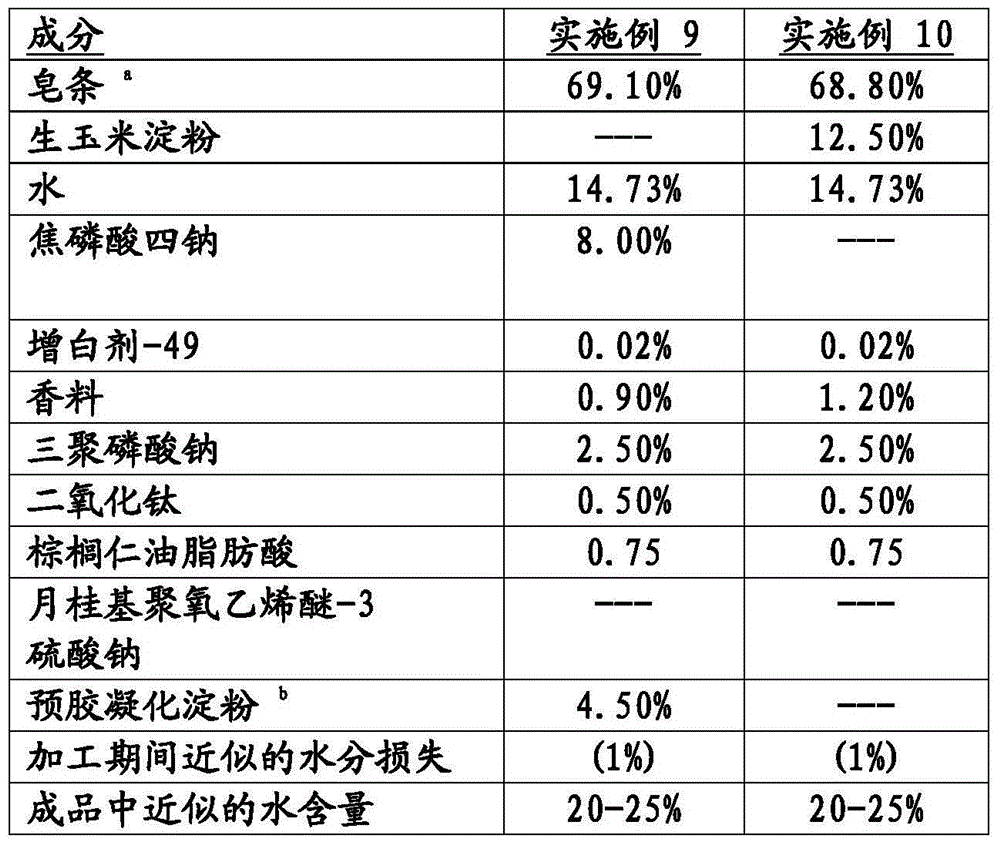

[0069] The following are non-limiting examples of cleansing bar compositions of the present invention. The amount of each ingredient is an approximate weight percent based on the weight of the bar soap composition.

[0070]

[0071]

[0072]

[0073] a The bars used in these examples have the following approximate composition: about 85% anhydrous soap (50% tallow / 30% palm stearic acid / 20% palm kernel oil (or 20% coconut oil)); about 0.2% free citric acid; about 0.2% sodium citrate; about 0.05% tetrasodium DPTA; about 0.05% tetrasodium HEDP; about 0.6% sodium chloride; about 1% glycerin; and about 12% to About 18% water, the balance is unsaponifiable substances. These percentages are by weight of the bar.

[0074] b Pregelatinized starch is available under the trade name PREGEL-A M 0300 from Tianjin Dingfeng Starch Development Co., Ltd., Tianjin, China.

[0075] In these examples, soap bars can be made via conventional methods involving a supporting step and a vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com