Method for enabling nano molten iron purifying modifier to be used in austenite ductile cast iron wear-resistant casting

A modification agent, austeric technology, applied in the field of ausferitic ductile iron wear-resistant castings, nanometer molten iron purification modification agent, can solve the problems of difficulty in adding nanoparticles, restricting the application of nanomaterials, etc., to reduce inclusions and improve mechanical properties Performance, the effect of reducing slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

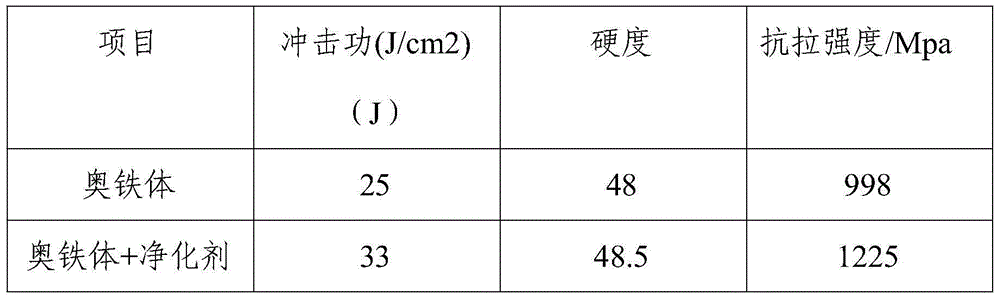

Examples

Embodiment 1

[0025] The method of using nanometer molten iron purification and modification agent in ausferitic ductile iron wear-resistant castings, adding nanometer molten iron purification modification agent is: after the conventional deoxidation of molten steel, a certain amount of nanometer molten iron purification agent is added to the ladle for strengthening Deoxidation and desulfurization, further degassing at the same time, fully stirred by the impact force of molten iron when tapping, so that the molten steel is greatly purified, including the following steps:

[0026] Step 1, smelting molten iron;

[0027] Step 2, spheroidizing treatment: the spheroidizing agent is placed on the bottom of the ladle by the flushing method, and the bottom of the ladle is used as a dam so that the molten iron can convect. Clean the processed molten iron slag and add covering agent, add 1.2kg covering agent for every 100kg molten iron;

[0028] The third step, pouring: the pouring temperature of mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com