A method for removing part of metal cobalt in polycrystalline diamond composite sheet by electrolysis

A technology of polycrystalline diamond and composite sheet, which is applied in the field of cobalt removal, to achieve the effects of improving heat resistance and wear resistance, small impact, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

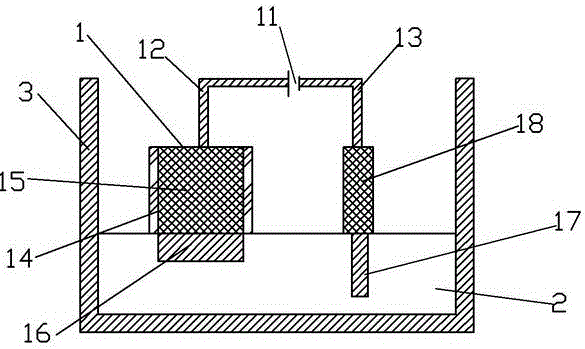

[0010] see figure 1 As shown in the figure, using the basic working principle of electrolytic metal, the polycrystalline diamond composite sheet is used as the object of electrolysis, and the cobalt in the polycrystalline diamond composite sheet is removed by using electrolyte, electrolysis device, inert cathode and regulating voltage to obtain a decobalt Polycrystalline diamond compacts.

[0011] The device used in the method is composed of an electrolysis device 1, an electrolyte 2 and a beaker 3, the electrolysis device 1 is arranged in the beaker 3, and the lower end of the electrolysis device 1 is immersed in the electrolyte;

[0012] The electrolysis device 1 includes a power source 11, a first wire 12, a second wire 13, a protective shielding material 14, a cemented carbide substrate 15, a polycrystalline diamond layer 16, an inert metal 17 and a cathode shielding material 18. The two wires 13 are respectively fixed on both ends of the power supply 11 , the lower end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com