Non-woven fabric containing photocatalyst and formula and preparation method thereof

A photocatalyst, non-woven technology, applied in non-woven fabrics, textiles and papermaking, fiber types, etc., can solve the problems of air pollution, deodorization, self-cleaning and air purification, environmental pollution, etc. Long-lasting, long-lasting sterilization and purification function, and the effect of removing formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Viscose fiber: 210kg / t, polyester fiber: 490kg / t, styrene-acrylate crosslinking emulsion: 410kg / t, pure acrylate self-crosslinking emulsion: 136kg / t, photocatalyst titanium dioxide dispersion: 180kg / t, hair Foaming agent K-12: 3kg / t.

[0015] Viscose 1.5D*38MM: 30%;

[0016] Polyester 1.5D*38MM: 70%;

[0017] Styrene-acrylate crosslinked emulsion (anionic, solid content 50%, Tg=-30℃, viscosity <300 cps);

[0018] Pure acrylate self-crosslinking emulsion (anionic, 55% solid content, Tg=3℃, viscosity <300 cps,);

[0019] The solid content of the photocatalyst titanium dioxide dispersion is 10%; (supplier: Shanghai Jianghu Titanium White Chemical Products Co., Ltd.).

[0020] The polyester and viscose fibers are opened and carded, formed into a net, foam sizing and photocatalyst, and then dried and wound.

Embodiment 2

[0022] Viscose fiber: 220kg / t, polyester fiber: 510kg / t, styrene-acrylate crosslinking emulsion: 430kg / t, pure acrylate self-crosslinking emulsion: 145kg / t, photocatalyst titanium dioxide dispersion: 190 kg / t, Foaming agent K-12: 4kg / t.

[0023] Viscose 1.5D*38MM: 30%;

[0024] Polyester 1.5D*38MM: 70%;

[0025] Styrene-acrylate crosslinked emulsion (anionic, solid content 50%, Tg=-30℃, viscosity <300 cps);

[0026] Pure acrylate self-crosslinking emulsion (anionic, 55% solid content, Tg=3℃, viscosity <300 cps,);

[0027] The solid content of the photocatalyst titanium dioxide dispersion is 10%; (supplier: Shanghai Jianghu Titanium White Chemical Products Co., Ltd.).

[0028] The polyester and viscose fibers are opened and carded, formed into a net, foam sizing and photocatalyst, and then dried and wound.

Embodiment 3

[0030] Viscose fiber: 230kg / t, polyester fiber: 540kg / t, styrene-acrylate crosslinking emulsion: 450kg / t, pure acrylate self-crosslinking emulsion: 150kg / t, photocatalyst titanium dioxide dispersion: 200 kg / t, Foaming agent K-12: 5kg / t.

[0031] Viscose 1.5D*38MM: 30%;

[0032] Polyester 1.5D*38MM: 70%;

[0033] Styrene-acrylate crosslinked emulsion (anionic, solid content 50%, Tg=-30℃, viscosity <300 cps);

[0034] Pure acrylate self-crosslinking emulsion (anionic, 55% solid content, Tg=3℃, viscosity <300 cps,);

[0035] The solid content of the photocatalyst titanium dioxide dispersion is 10%; (supplier: Shanghai Jianghu Titanium White Chemical Products Co., Ltd.).

[0036] The polyester and viscose fibers are opened and carded, formed into a net, foam sizing and photocatalyst, and then dried and wound.

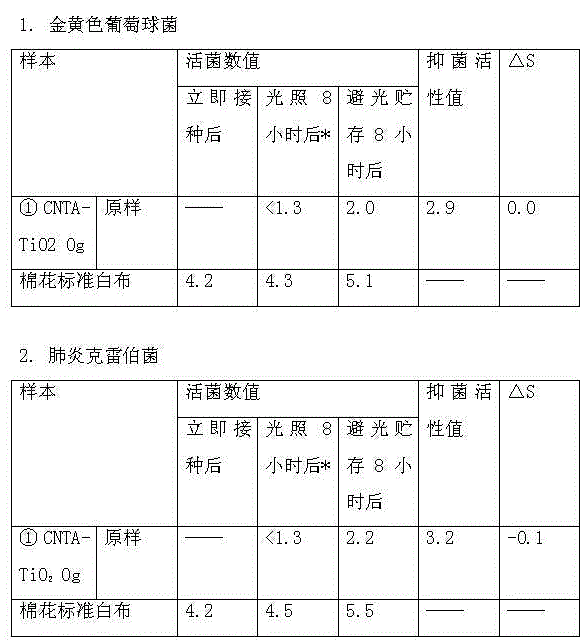

[0037] Indexes of the non-woven fabric prepared by the formula of the present invention:

[0038] Weight: 30+-2g / ㎡; Feel: soft

[0039] Width: 1.00M (or slitting as required); thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com