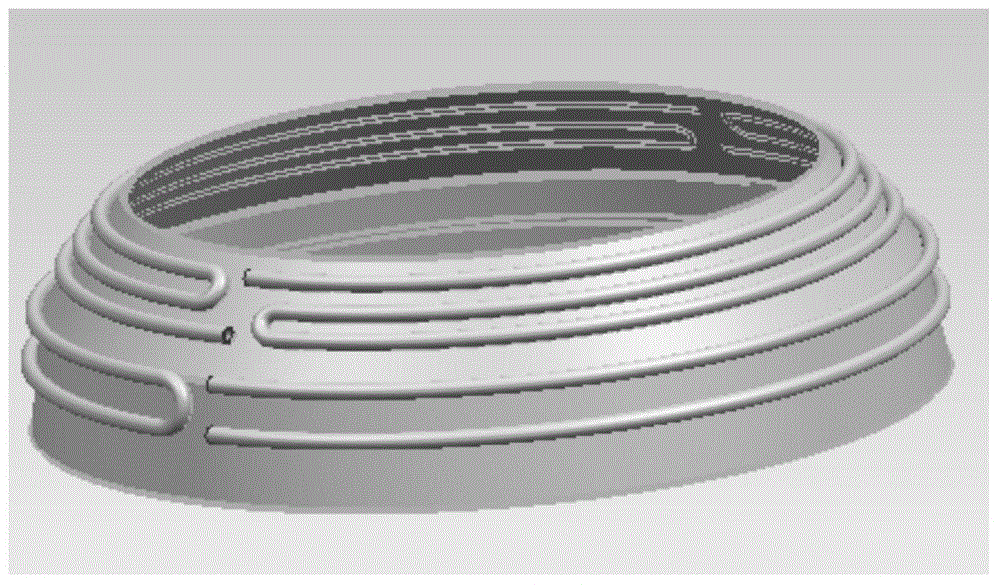

Optimum spacing obtaining method for cooling pipelines on back side of mirror body in extreme ultraviolet collecting system

A collection system and cooling pipeline technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of spot deformation, not paying attention to the high heat introduction of high-power light sources, and the reduction of the life of the mirror substrate and film layer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

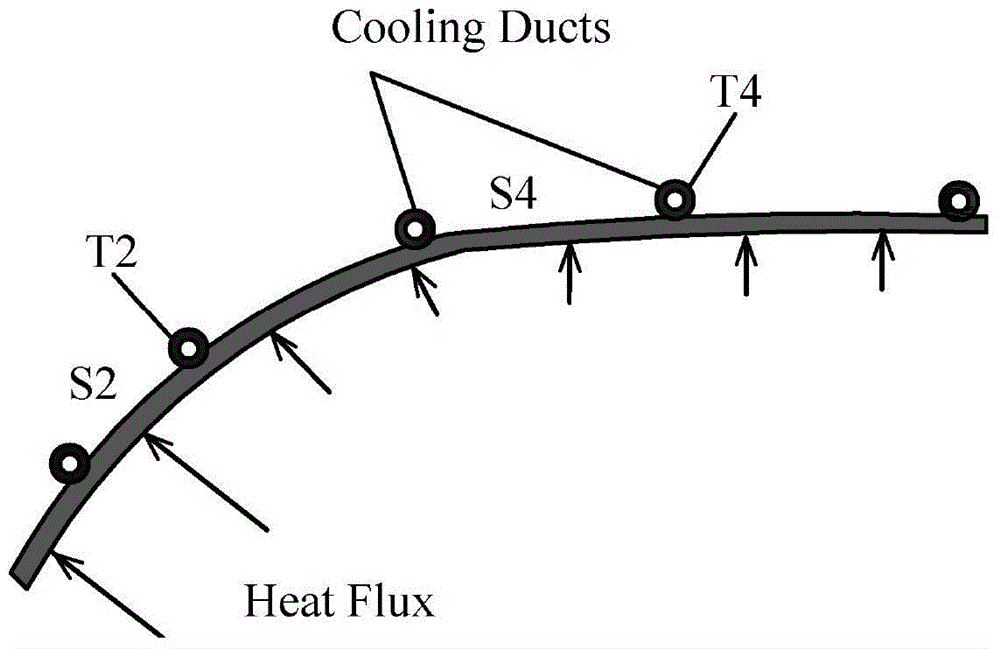

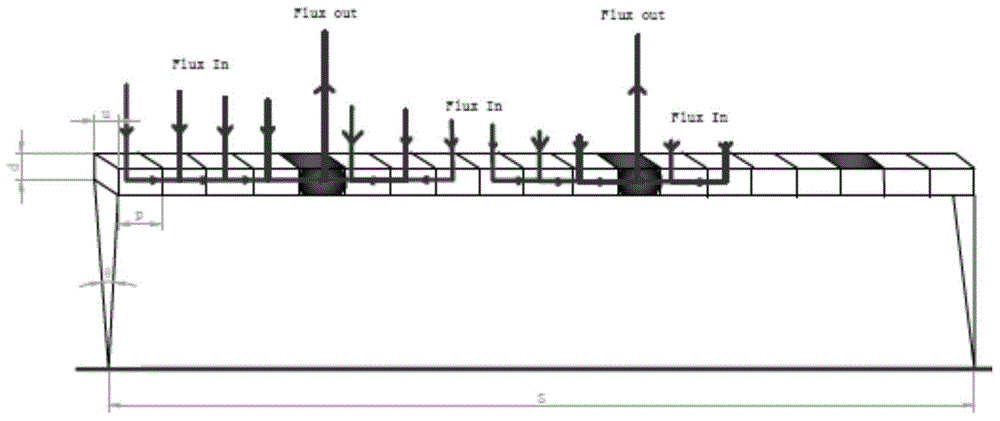

[0053] In the extreme ultraviolet light source collection system, for a given light source and a single-layer mirror body, the total heat flux density of the mirror surface is:

[0054] Hyperboloid part: fz(x)=3557*exp(-0.02009*x)-814.7*exp(-0.2342*x);

[0055] Ellipsoid part: fz(x)=0.00687*x.^3-2.149*x.^2+217.8*x-5381;

[0056] (The origin of the equation is the intersection point of the axis of the mirror body and the front face of the mirror body)

[0057] The inner diameter of the cooling water pipe is 5mm, and the outer diameter is 8mm; the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com