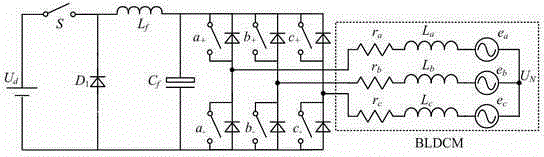

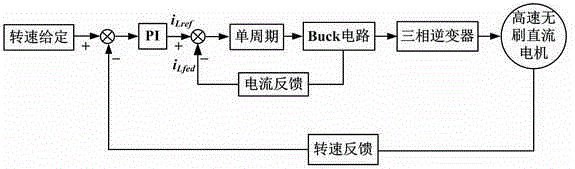

Active damping method of Buck circuit brushless direct current motor control system

A brushed DC motor and control system technology, applied in excitation or armature current control, etc., can solve problems such as capacitor boost, unstable motor phase current waveform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

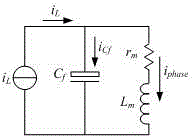

[0076] Example 1: Buck capacitors connected in parallel with virtual resistors

[0077] (1) Figure 5 is the equivalent circuit diagram after adding the damping resistor. Such as Figure 5 As shown, the inductor current keeps constant at the moment of commutation of the motor, which can be regarded as a constant current source, and its current value is i L . Capacitance C f It is connected in parallel with the motor phase winding at both ends of the inductance, r m is the motor phase resistance, L m is the motor phase inductance. R is the resistance value of the added virtual resistance, which is equivalently connected in parallel at both ends of the capacitor. according to Figure 5 , write the circuit equation in the complex frequency domain as follows:

[0078] i cf ( s ) . 1 Cs = u cf ...

Embodiment 2

[0094] Example 2: Buck capacitor in series with virtual resistor

[0095] (1) Figure 9 is the equivalent circuit diagram after adding the damping resistor. Such as Figure 9 As shown, the inductor current keeps constant at the moment of commutation of the motor, which can be regarded as a constant current source, and its current value is i L . Capacitance C f It is connected in parallel with the motor phase winding at both ends of the inductance, r m is the motor phase resistance, L m is the motor phase inductance. R is the resistance value of the added virtual resistance, which is equivalently connected in series with the capacitor branch. according to Figure 9 , write the circuit equation in the complex frequency domain as follows:

[0096] i cf ( R + 1 Cs ) = u cf

[0097] ...

Embodiment 3

[0109] Embodiment 3: Inverter bus bar series virtual resistance

[0110] (1) Figure 13 is the equivalent circuit diagram after adding the damping resistor. Such as Figure 13 As shown, the inductor current keeps constant at the moment of commutation of the motor, which can be regarded as a constant current source, and its current value is i L . Capacitance C f It is connected in parallel with the motor phase winding at both ends of the inductance, r m is the motor phase resistance, L m is the motor phase inductance. R is the resistance value of the added virtual resistance, which is equivalently connected in series on the inverter bus branch. according to Figure 13 , write the circuit equation in the complex frequency domain as follows:

[0111] i cf ( R + 1 Cs ) = u cf

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com