Wide thick titanium alloy plate rolling method

A titanium alloy and wide-width technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of performance deterioration, high resistance to deformation, and coarse material structure, so as to reduce production costs, improve production efficiency, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Place the 300×900×1500mm (thickness×width×length) TC4 ELI titanium alloy slab in a heating furnace, and heat it at a temperature of 950°C for 400 minutes;

[0021] Step 2: Send the TC4ELI slab heated by step 1 into a 3300mm rolling mill with a width of 1500mm for rolling. The rolling is divided into 28 passes. The deformation of each pass is 2-8%, and the rolling rate is controlled at 1m / s~10m / s; use an infrared thermometer to monitor the temperature of the TC4ELI titanium alloy slab to ensure that the final rolling temperature is not lower than 800°C, and obtain a finished titanium alloy thick plate with a thickness of 90mm;

[0022] Step 3: Rapidly cool the finished plate described in Step 2 to below 300° C. by using an online water spray cooling method.

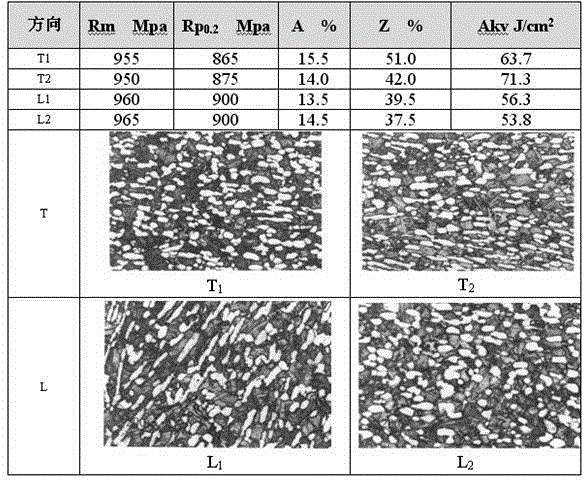

[0023] Step 4: Heat the cooled finished plate at a temperature of 920°C for about 2 hours for solution annealing to obtain a finished titanium alloy thick plate. After testing and testing, its performance da...

Embodiment 2

[0025] Step 1: Place the 200×1700×3200mm (thickness×width×length) TC4 ELI titanium alloy slab in a heating furnace, and heat it at 950°C for 280 minutes;

[0026] Step 2: Send the TC4 ELI slab heated by step 1 into a 3300mm rolling mill with a width of 3200mm for rolling. The rolling is divided into 18 passes. The deformation of each pass is 2~8%, and the rolling rate is controlled. At 1m / s~10m / s; use an infrared thermometer to monitor the temperature of the TC4 ELI titanium alloy slab to ensure that the final rolling temperature is not lower than 800°C, and obtain a finished titanium alloy thick plate with a thickness of 90mm;

[0027] Step 3: Rapidly cool the finished plate described in Step 2 to below 300° C. by using an online water spray cooling method.

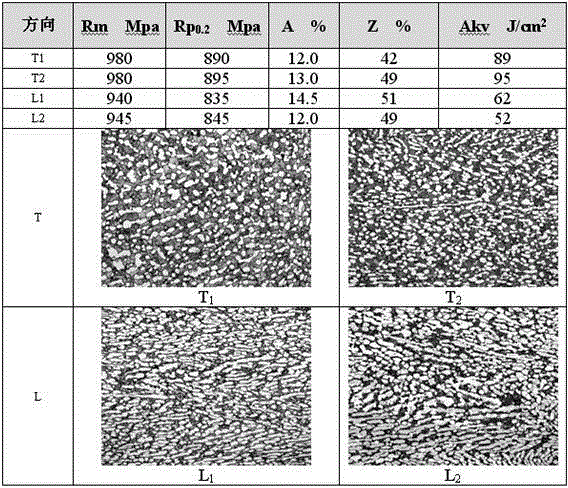

[0028] Step 4: Heat the cooled finished plate at a temperature of 920°C for about 2 hours for solution annealing to obtain a finished titanium alloy thick plate. After testing and testing, its performance data and micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com