Method preparing abamectin Bla fine powder by secondary crystallization in abamectin Bla

A technology of abamectin and crystallization mother liquor, which is applied to the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of abamectin B1a product purity and low yield, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

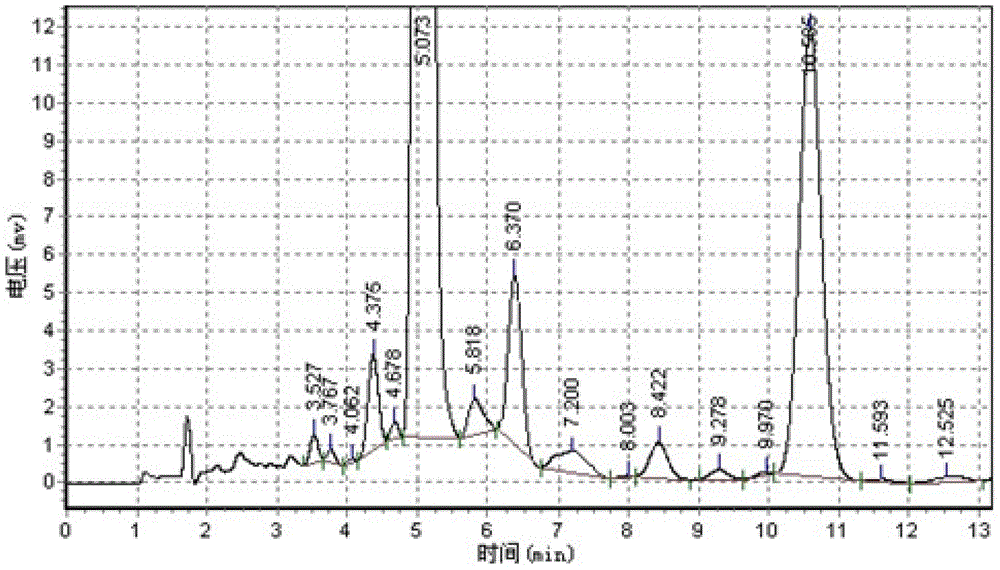

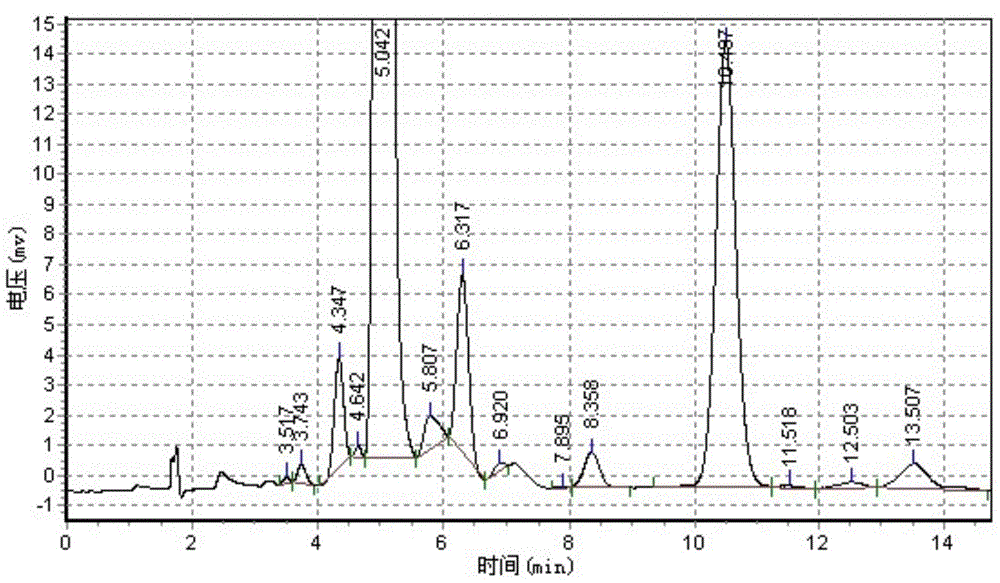

Image

Examples

Embodiment 1

[0040] A method for preparing the fine powder of abamectin B1a by secondary crystallization in an abamectin B1a crystallization mother liquor, comprising the following steps:

[0041] 1. Weigh 1500ml of abamectin B1a crystallization mother liquor, heat up to 70°C for vacuum distillation for 2 hours, and concentrate the solution into a paste to obtain a thick ointment. The vacuum degree during concentration is -0.07MPa.

[0042] 2. Weigh the weight of the paste obtained above as 450g (content: Abamectin B1a5.2%), add 1150ml of sec-butyl acetate, heat up to 60°C and stir to dissolve for 30 minutes until the ointment thick material is completely dissolved, then add 350ml of saturated Saline, stirred at 80°C for 1 hour, then allowed to stand for 30 minutes, then separated the water, repeated the above washing twice, separated the layers, and removed the water phase to obtain a sec-butyl acetate solution.

[0043] 3. The obtained sec-butyl acetate solution was heated to 95° C. with...

Embodiment 2

[0046] A method for preparing the fine powder of abamectin B1a by secondary crystallization in an abamectin B1a crystallization mother liquor, comprising the following steps:

[0047] 1. Weigh 1500ml of abamectin B1a crystallization mother liquor, heat up to 78°C for vacuum distillation for 2 hours, concentrate the solution into a paste to obtain a thick ointment, and the vacuum degree during concentration is -0.06MPa.

[0048] 2. Weigh the weight of the paste obtained above as 460g (content: Abamectin B1a5.1%), add 1100ml of sec-butyl acetate, heat up to 60°C and stir to dissolve for 30 minutes until the ointment thick material is completely dissolved, then add 350ml of saturated Saline, stirred at 80°C for 1 hour, then allowed to stand for 30 minutes, then separated the water, repeated the above washing twice, separated the layers, and removed the water phase to obtain a sec-butyl acetate solution.

[0049] 3. The obtained sec-butyl acetate solution was heated to 94° C. with...

Embodiment 3

[0052] A method for preparing the fine powder of abamectin B1a by secondary crystallization in an abamectin B1a crystallization mother liquor, comprising the following steps:

[0053] 1. Weigh 1500ml of abamectin B1a crystallization mother liquor, heat up to 68° C. for 2 hours and distill in vacuum for 2 hours, and concentrate the solution into a paste to obtain a thick ointment. The vacuum degree during concentration is -0.05MPa.

[0054] 2. Weigh the weight of the paste obtained above as 460g (content: Abamectin B1a5.0%), add 960ml of sec-butyl acetate, heat up to 60°C and stir to dissolve for 30 minutes until the ointment thick material is completely dissolved, then add 350ml of saturated Saline, stirred at 80°C for 1 hour, then allowed to stand for 30 minutes, then separated the water, repeated the above washing twice, separated the layers, and removed the water phase to obtain a sec-butyl acetate solution.

[0055] 3. Use a water bath to raise the temperature of the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com