Shock-absorption foamed rubber

A technology of foam rubber and silicone rubber, which is applied in the field of shock-absorbing foam rubber to achieve good damping performance, excellent shock-absorbing effect, and good sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

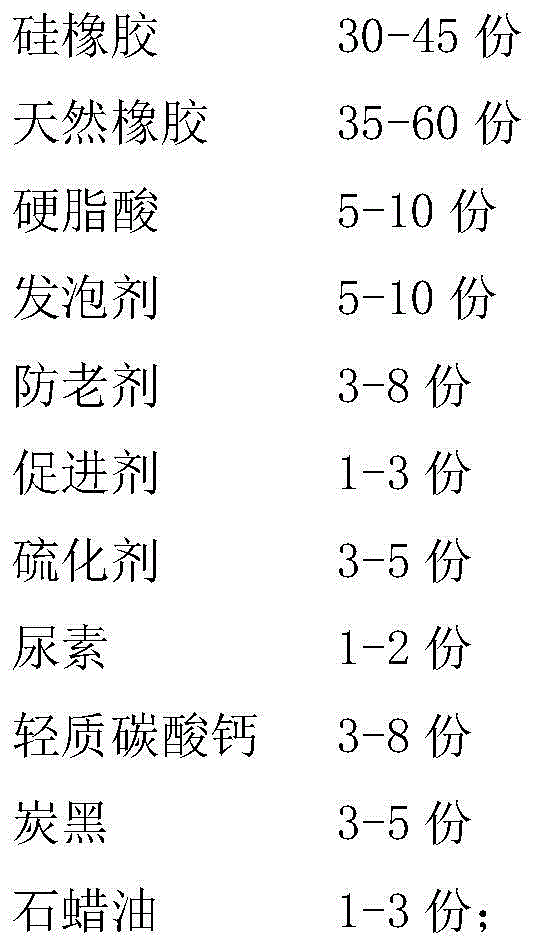

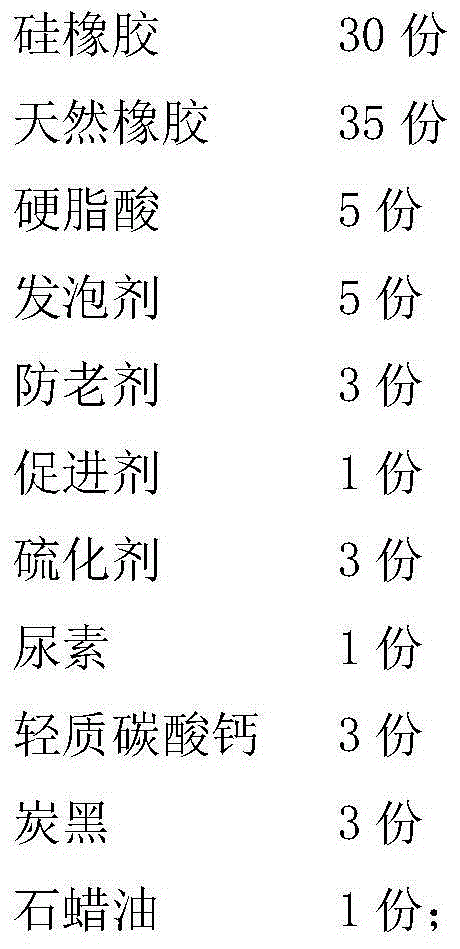

[0019] The invention discloses a shock-absorbing foam rubber, which comprises the following raw materials measured in parts by mass:

[0020]

[0021] The preparation method of described shock-absorbing foam rubber is:

[0022] Step 1. Mix natural rubber, light calcium carbonate, stearic acid, urea, carbon black, and paraffin oil evenly, put them into an open mill for mastication, then add foaming agent, anti-aging agent, accelerator, and finally add vulcanizing agent , to prepare the rubber compound, the distance between the rollers for masticating is 0.5cm, and the masticating temperature is 40°C;

[0023] Step 2: Put the silicone rubber into the open mixer for masticating, and after the silicone rubber is softened, add the rubber compound prepared in step 1 for plasticizing until the silicone rubber and the rubber compound prepared in step 1 are evenly mixed, and then release the sheet , to obtain the secondary compound rubber, the distance between the rollers for masti...

Embodiment 2

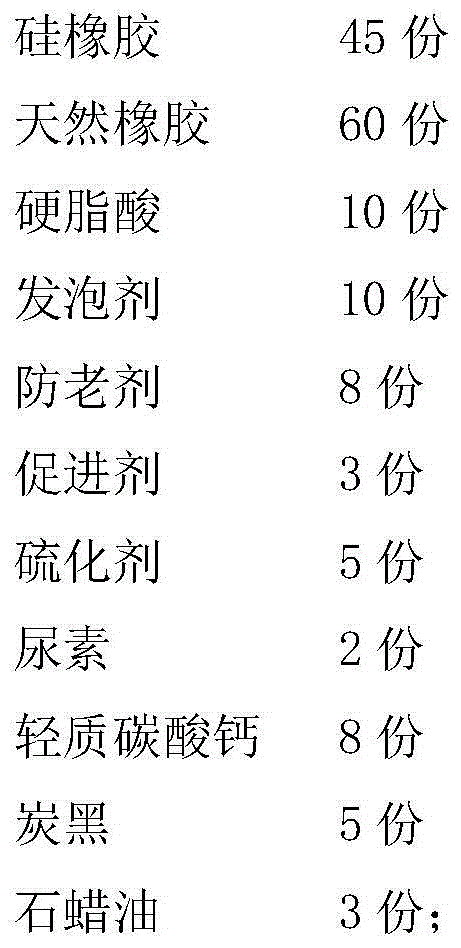

[0027] The invention discloses a shock-absorbing foam rubber, which comprises the following raw materials measured in parts by mass:

[0028]

[0029] The preparation method of described shock-absorbing foam rubber is:

[0030] Step 1. Mix natural rubber, light calcium carbonate, stearic acid, urea, carbon black, and paraffin oil evenly, put them into an open mill for mastication, then add foaming agent, anti-aging agent, accelerator, and finally add vulcanizing agent , to prepare the compounded rubber, the distance between the rollers for masticating is 1cm, and the masticating temperature is 50°C;

[0031] Step 2: Put the silicone rubber into the open mixer for masticating, and after the silicone rubber is softened, add the rubber compound prepared in step 1 for plasticizing until the silicone rubber and the rubber compound prepared in step 1 are evenly mixed, and then release the sheet , to obtain the secondary compound rubber, the distance between the rollers for masti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com