A highly stable cyanide-free alkaline zinc plating solution

A cyanide-free alkaline galvanizing technology with high stability, applied in the field of electroplating, can solve the problems of low stability and achieve the effects of improved stability, easy maintenance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Hanging galvanizing process of the present invention is as follows:

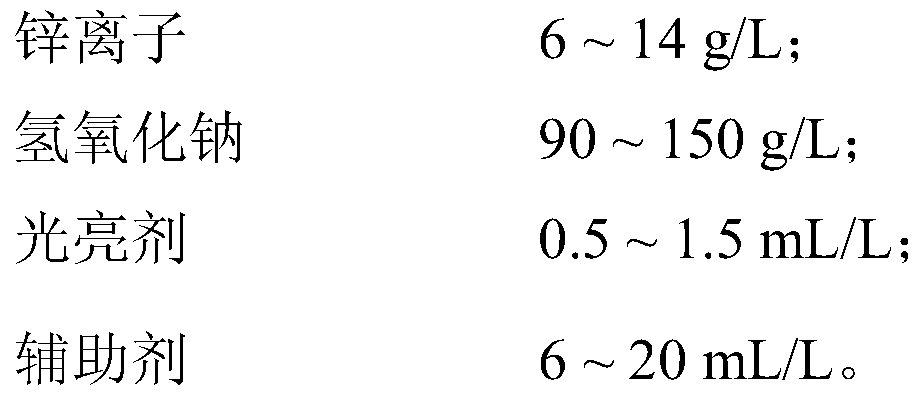

[0018]

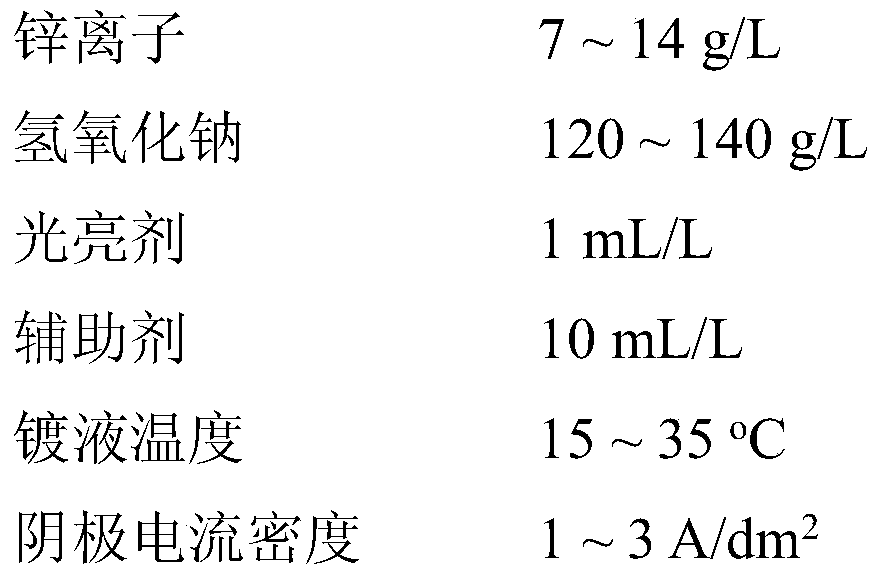

[0019]

[0020] The preparation method of the brightener is as follows: dissolve 30-50 g of sodium metabisulfite in 900 mL of water, and then add 20-50 g of 3-methoxy-4-hydroxybenzaldehyde or 3,4-dimethoxybenzaldehyde or 4-formaldehyde Oxybenzaldehyde, stir until the aldehyde compound is completely dissolved, and then add water to 1000mL.

[0021] The preparation method of the auxiliary agent is as follows: 50-150g of low-molecular-weight polyacrylamide, 20-50g of the reactant of imidazole and epichlorohydrin, 20-50g of pyridinium propane sulfobetaine or pyridinium hydroxypropyl sulfobetaine Add betaine to 750g of water, stir to dissolve, and then add water to 1000mL.

[0022] Hall cell test results:

[0023] Carry out 250mL Hall cell test, each test piece is plated with 1A current for 10min, add 0.15mL of brightener and 0.1mL of auxiliary agent for each plated 6 test pieces, add zinc...

Embodiment 2

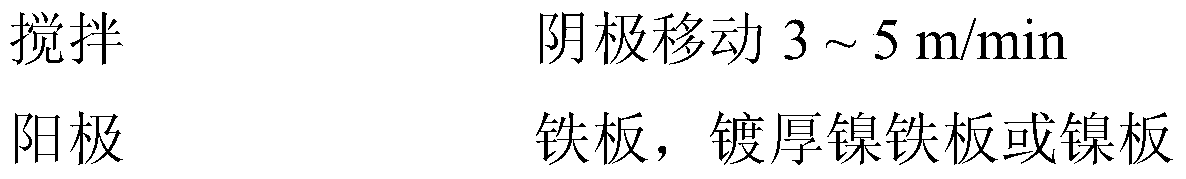

[0031] Barrel galvanizing process of the present invention is as follows:

[0032]

[0033]

[0034] The preparation method of the brightener is as follows: dissolve 30-50 g of sodium metabisulfite in 900 mL of water, and then add 20-50 g of 3-methoxy-4-hydroxybenzaldehyde or 3,4-dimethoxybenzaldehyde or 4-formaldehyde Oxybenzaldehyde, stir until the aldehyde compound is completely dissolved, and then add water to 1000mL.

[0035] The preparation method of the auxiliary agent is as follows: 50-150 g of low molecular weight polyacrylamide, 20-50 g of the reactant of imidazole and epichlorohydrin, 20-50 g of pyridinium propane sultaine or pyridinium hydroxypropyl sultaine One of the alkalis, add 750g of water, stir to dissolve, and then add water to 1000mL.

[0036] According to this process, 80L of plating solution was prepared, and the actual barrel plating test was carried out for 20 hours. The performance of the plating solution remained good, and the coating test res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com