Device and method for detecting abrasion resistance of honeycomb-shaped ceramic-metal composite material

A technology of metal composite materials and honeycomb ceramics, which is applied in the direction of testing wear resistance, etc., can solve the influence of the comparison results of the wear resistance of wear samples, and cannot reflect the advantages of the wear resistance of honeycomb ceramic-metal composite materials. Quickly find out the wear resistance of honeycomb ceramic-metal composites and other issues, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

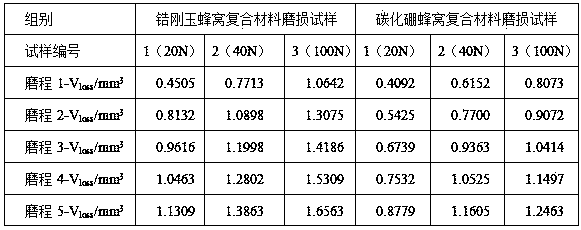

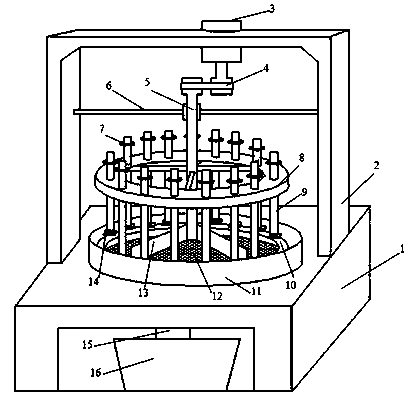

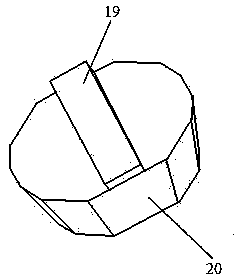

[0042] Embodiment 1: as Figure 1-9 As shown, a testing device for the wear performance of honeycomb ceramic-metal composite materials includes a workbench 1, a motor bracket 2, an adjustable speed motor 3, a conveyor belt 4, a rotating spindle 5, a rotating shaft bracket 6, a weight table 7, and a rotating shaft. Ring 8, sample rotating shaft 9, wear rail 10, retaining ring 11, abrasive screen 12, collecting plate 13, fixture 14, abrasive funnel 15, abrasive recovery cylinder 16, tough metal column 17, wear-resistant composite area 18, test Sample clamping step 19, feeding slope 20, electronic output instrument of hardness tester 21, electronic output instrument of quantitative metallographic microscope 22, electronic output instrument of precision balance 23, computer 24; wherein the workbench 1 and the motor bracket 2 are welded together, and the motor The bracket 2 and the adjustable speed motor 3 are connected together by bolts, the adjustable speed motor 3 drives the rot...

Embodiment 2

[0055] Embodiment 2: as Figure 1-9As shown, a testing device for the wear performance of honeycomb ceramic-metal composite materials includes a workbench 1, a motor bracket 2, an adjustable speed motor 3, a conveyor belt 4, a rotating spindle 5, a rotating shaft bracket 6, a weight table 7, and a rotating shaft. Ring 8, sample rotating shaft 9, wear rail 10, retaining ring 11, abrasive screen 12, collecting plate 13, fixture 14, abrasive funnel 15, abrasive recovery cylinder 16, tough metal column 17, wear-resistant composite area 18, test Sample clamping step 19, feeding slope 20, electronic output instrument of hardness tester 21, electronic output instrument of quantitative metallographic microscope 22, electronic output instrument of precision balance 23, computer 24; wherein the workbench 1 and the motor bracket 2 are welded together, and the motor The bracket 2 and the adjustable speed motor 3 are connected together by bolts, the adjustable speed motor 3 drives the rota...

Embodiment 3

[0058] Embodiment 3: as Figure 1-9 As shown, a testing device for the wear performance of honeycomb ceramic-metal composite materials includes a workbench 1, a motor bracket 2, an adjustable speed motor 3, a conveyor belt 4, a rotating spindle 5, a rotating shaft bracket 6, a weight table 7, and a rotating shaft. Ring 8, sample rotating shaft 9, wear rail 10, retaining ring 11, abrasive screen 12, collecting plate 13, fixture 14, abrasive funnel 15, abrasive recovery cylinder 16, tough metal column 17, wear-resistant composite area 18, test Sample clamping step 19, feeding slope 20, electronic output instrument of hardness tester 21, electronic output instrument of quantitative metallographic microscope 22, electronic output instrument of precision balance 23, computer 24; wherein the workbench 1 and the motor bracket 2 are welded together, and the motor The bracket 2 and the adjustable speed motor 3 are connected together by bolts, the adjustable speed motor 3 drives the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com