Experimental device for gas thermal diffusion test in loose coal

An experimental device and thermal diffusion technology, which are applied in the field of experimental devices for testing gas thermal diffusion in loose coal, can solve problems such as insufficient understanding of mutual relationships, safety and health hazards of safety production workers, and little research on the mechanism of action and influencing factors. , to achieve the effect of easy control, improved heat utilization efficiency, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

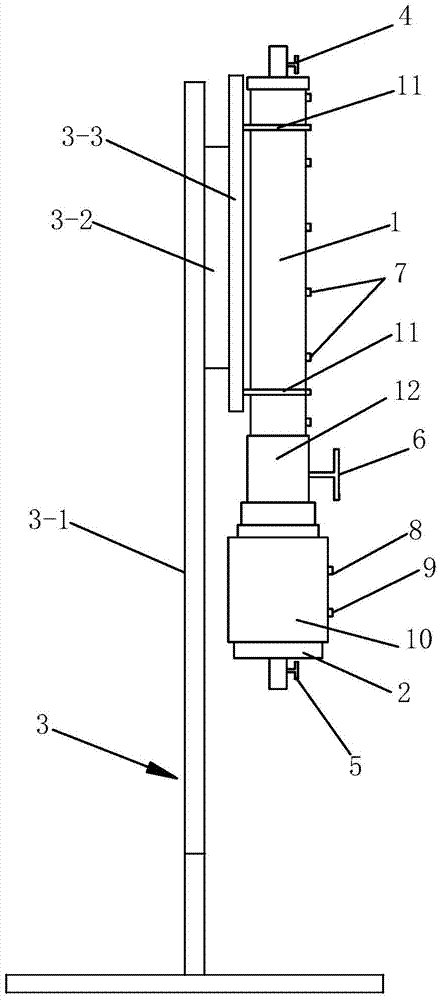

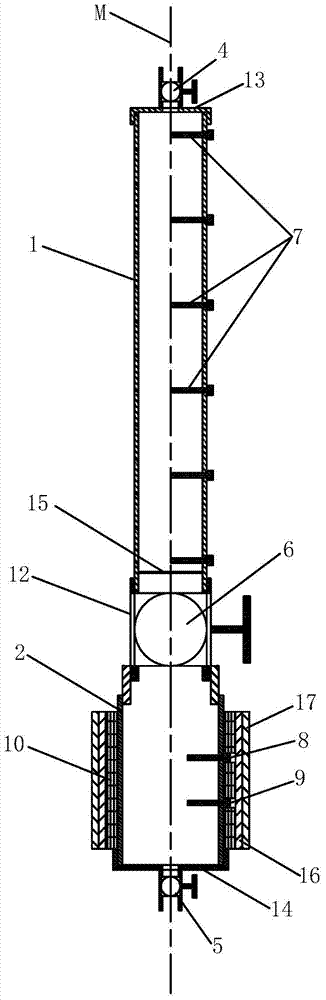

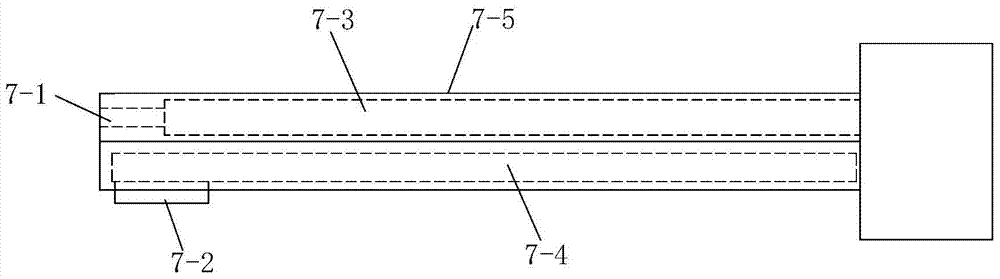

[0036] Such as figure 1 , figure 2 and image 3 The shown experimental device for gas thermal diffusion test in loose coal includes a coal tube 1 for containing loose coal, a gas tube 2 for generating hot air, and a tube 1 for supporting the coal and the support 3 of the gas containing pipe 2, the support 3 is connected with the coal body containing pipe 1; one end of the coal body containing pipe 1 is connected with the end of the gas containing pipe 2 through a variable diameter joint 12, and the coal body containing The other end of the pipe 1 is provided with a first valve 4 for closing or opening its end opening, and the other end of the gas containing pipe 2 is provided with a second valve 5 for closing or opening its end opening. The joint 12 is provided with a third valve 6 for controlling the connection or shut-off of the coal body storage pipe 1 and the gas storage pipe 2. The coal body storage pipe 1 is provided with a partition 15, and the partition 15 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com